Use these copy-ready Gantt templates to plan your plush project backwards—from launch date to sampling, production, packing, and shipping.

Uniomy’s controlled planning system helps solve the common timeline blockers below:

8 blocks same for every custom plush project

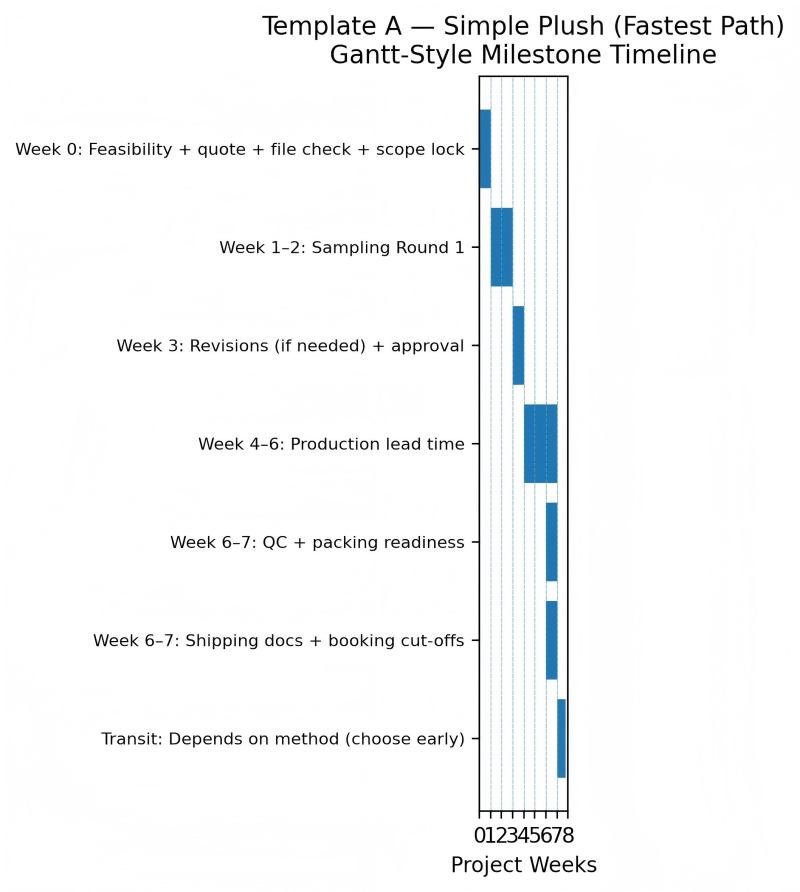

Learn the fastest way to plan a custom plush timeline.

Simple designs move fastest when materials and approvals don’t drift.

Use this template for simple plush designs with standard fabrics, minimal accessories, and straightforward embroidery. It fits pilot programs and fast launches because sampling risk is low and production lead time is easier to stabilize.

Best for

Gantt blocks

Key inputs to lock early

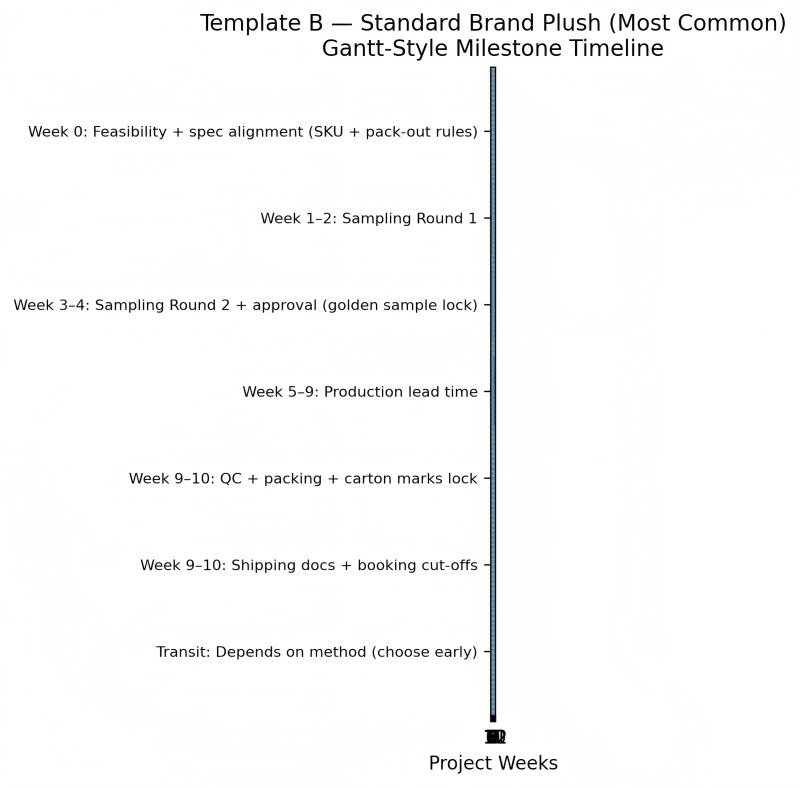

Most common path for retail and e-commerce brands.

Use this for typical brand plush programs: multiple colors/variants, mixed decoration (embroidery + patch/print), packaging labels/carton marks, and 1–2 sampling rounds. It’s the most realistic template for clean approvals and repeatable reorders.

Best for

Gantt blocks (copy-ready)

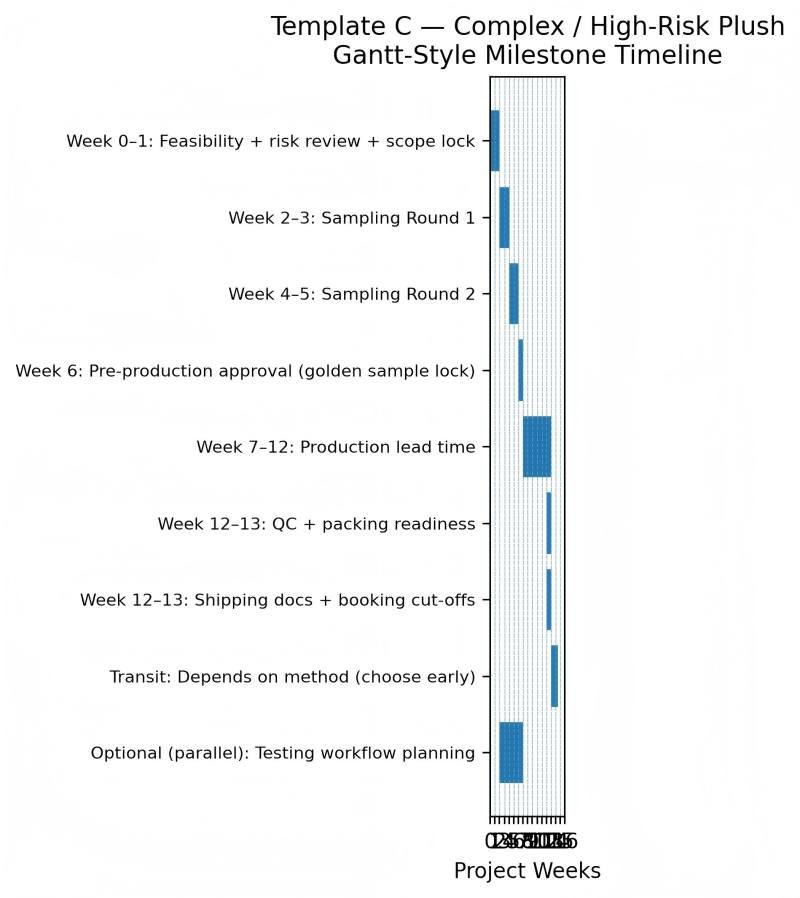

Accessories, Electronics, Compliance checkpoints

Use this when you have magnets/electronics, complex attachments, special prints/coatings, strict market/channel requirements, or multiple approvers. Plan more sampling time, lock final-spec earlier, and allocate buffer for testing and documentation—ideally running testing in parallel where possible.

Best for

Gantt blocks (copy-ready)

Critical must-not-change items before any testing submission

Shipping assumptions miss launch dates more often than production does.

Launch dates are missed more often due to shipping assumptions and document cut-offs than sewing time. Choose shipping method early, lock carton specs to control dimensional weight, and draft shipping documents before dispatch. Split shipments are the best strategy when you need speed and cost control.

| Risk Trigger | What Happens | Lock Point |

|---|---|---|

| Late ship method decision | re-plan booking & arrival | before production ends |

| Carton dims/qty changed late | DIM weight jumps / re-pack | before packing starts |

| CI/PL/carton marks not aligned | document hold / miss cut-off | pre-dispatch draft stage |

| Launch needs speed + cost | overpay air or miss date | plan split shipment early |

Best practices

Clear inputs produce a timeline your team can approve internally.

Back-planning is fast when key inputs are clear. Send your launch/arrival date, channel, SKU structure, accessories, packaging, and shipping preference. We’ll return a realistic lead time plan with Gantt-style milestones and suggested buffers—ready to share with purchasing, marketing, and QA.

Please share

Most delays are predictable—and preventable with early locks.

Most delays come from the same causes: late spec changes, unclear labels/carton rules, too many sample revisions, and compliance/testing started too late. Prevent them with early scope lock, fewer moving parts, one decision owner for approvals, and consolidated feedback per revision round.

Top delay risks

Q1: Can you guarantee a fixed lead time?

Lead time depends on complexity, revision rounds, and shipping method. We provide a realistic plan and help lock risk items early to keep timelines predictable.

Q2: How many sampling rounds should I plan for?

Simple projects may need 1 round; standard projects often need 1–2; complex projects should plan more buffer and stricter spec lock.

Q3: What’s the fastest way to hit a hard launch date?

Lock must-not-change items early, reduce variants, and use split shipping when needed.

Share your launch date, market/channel, product configuration, and shipping preference. We’ll return an editable Gantt plan (milestones + recommended buffer) aligned with production lead time, document readiness, and shipping cut-offs.

I am Nika, our team would be happy to meet you and help to build your brand plush.