Carton disputes rarely come from plush quality—they come from unclear cartonization, inconsistent carton qty, missing marks, or late pallet rules. Lock these early and your shipment clears receiving faster, with lower chargeable weight and fewer claims.

Most common failure modes (and the backstop)

3 key impacts of carton specs: freight cost, receiving holds, and claims

Carton specs decide what you pay (chargeable weight), how fast you receive (scan/put-away), and how clearly disputes are resolved (damage, shortage, mixed-SKU errors). This page converts carton conversations into a short, enforceable spec your supplier and warehouse can execute without rework.

Cartons directly affect three outcomes

The boundary what changes everything

If your destination has strict receiving rules (labels, pallets, mixed-SKU limits), carton specs must be designed around those constraints—not guessed later.

Use one shared vocabulary so quotes, CI/PL, labels, and receiving scans all match.

Misalignment happens when the factory, forwarder, and 3PL use the same words differently. These definitions make cartonization “versionable” so quotes, packing lists, carton labels, and receiving scans reference the same packing logic across sampling, bulk, and repeat orders.

Definition Term list

| Term | Definition (plain-English) | Where used |

|---|---|---|

| Cartonization | The full packing data set: pcs/ctn + carton count + dims + GW/NW. | Booking file, CI/PL drafts, warehouse receiving |

| Unit pack | How each unit is packed (polybag/box/kit). | Carton size baseline, protection rules |

| Master carton | The outer carton holding multiple unit packs. | Packing execution, shipping handling |

| Pcs/ctn | Units per master carton (standard + remainder rule). | Carton marks, packing list accuracy |

| Remainder carton | The last carton that may have fewer units than the standard. | Carton marks + packing list notes |

| GW / NW | Gross weight vs net weight (with carton vs product only). | Carton marks, booking, CI/PL |

| Carton marks | The identification printed/labeled on outer cartons. | Receiving scan, put-away, claims verification |

| Label placement | Where the carton label goes for scanning consistency. | Warehouse receiving SOP |

| Mixed carton | A carton containing multiple SKUs/variants (only if allowed). | Receiving policy, carton marks, PL/ASN match |

| Palletization | Cartons stacked on pallets with height/weight/wrap rules. | Retail DC/3PL receiving, routing requirements |

| CI/PL | Commercial Invoice / Packing List documents for shipping. | Customs + receiving checks |

| ASN | Advance Shipping Notice (if your warehouse uses it). | 3PL/retailer receiving workflows |

These fields are what customs and warehouse teams use to verify cartons against paperwork—keep them consistent across CI, PL, and carton marks.

Field checklist (6–8)

Mini rule (optional line under checklist)

If CI/PL can’t be reconciled with carton marks and cartonization, receiving holds and claim disputes become much harder to resolve.

Carton labels are for scanning and put-away—keep the format short, consistent, and aligned with PL fields.

Field checklist (6–8)

Placement rule (one short line)

Place labels on two adjacent sides at consistent height—do not tape over scan fields.

Forwarders book space based on cartonization and totals. Missing or inconsistent packing data often causes re-quotes, re-booking, or pickup delays.

Field checklist (6–8)

Mini rule (optional line)

If packing data changes after booking (dims/carton count), freight cost and ETD/ETA plans may need to be recalculated.

Destination rules, load method, and mixed-SKU policy determine carton qty, labels, and pallet constraints.

Carton optimization only works after three inputs are locked: destination receiving type, whether pallets are required, and whether mixed-SKU cartons are allowed. These rules decide carton quantity, carton marks, label placement, and whether pallet limits become the real bottleneck.

FBA / 3PL / Retail DC / General Warehouse

Why it matters: Sets receiving rules, labels, and hold risk.

Palletized Required / Floor-Loaded / Optional

Why it matters: Determines whether pallet limits become hard constraints.

Options:

Not Allowed

Allowed with Disclosure (carton must say “MIXED”)

Allowed with Carton-Level Breakdown (SKU qty must match PL/ASN)

Why it matters: Prevents count errors and receiving holds.

Output Mapping (What changes when you choose)

This one-page spec turns “preferences” into enforceable fields that prevent oversize cartons and receiving rework.

A carton spec sheet is a short, enforceable requirement—not a discussion. It defines strength, target dimensions, max gross weight, carton quantity rules, sealing/protection, and labeling rules. Once locked, carton changes won’t silently increase chargeable weight or trigger receiving holds.

| Field (Required) | What it controls | Recommended / Example | Who provides | Where it’s used |

|---|---|---|---|---|

| Destination type | Receiving constraints & label rules | 3PL / Retail DC / FBA / General warehouse | Buyer | Packing plan + marks |

| Load method | Carton design vs pallet limits | Palletized / Floor-loaded / TBD | Buyer + Forwarder | Packing + booking |

| Unit pack type | Carton size baseline | 1 pc/polybag; 1 pc/box; kit | Buyer + Factory | Dims + protection |

| Carton grade/strength | Damage risk & stacking | 5-ply (or buyer SOP spec) | Buyer/Factory propose | Carton purchase + QC |

| Standard pcs/ctn | Receiving consistency | 24 pcs/ctn (example) | Buyer + Factory | PL + carton marks |

| Remainder rule | Prevent random cartons | Last carton allowed range + special mark | Buyer | PL + carton marks |

| Max GW per carton | Handling + damage | Follow warehouse SOP (often capped) | Buyer/Warehouse | Packing + receiving |

| Target dims (range) | Chargeable weight control | “Within range; no oversize w/o approval” | Factory propose + Buyer approve | Quote + booking + PL |

| Mixed-SKU policy | Mix-up risk | Not allowed / allowed w breakdown | Buyer | Marks + PL + ASN |

| Inner protection | Crush/abrasion | Polybag; divider if needed | Buyer + Factory | Packing execution |

| Sealing method | Carton integrity | H-tape; reinforcement if needed | Factory | Packing SOP |

| Label placement | Scan speed | Two adjacent sides; consistent height | Buyer/Warehouse | Receiving |

| Carton mark format | Traceability | PO + SKU + carton no. + qty + dims | Buyer | Carton labels |

| Pallet required? | Hard constraints | Yes/No/Optional | Buyer + Forwarder | Packing method |

| Pallet size | Footprint | Per destination SOP | Warehouse | Pallet plan |

| Max pallet height | Fit + stability | Per destination SOP | Warehouse | Pallet plan |

| Max pallet weight | Handling | Per destination SOP | Warehouse | Pallet plan |

| Wrap/banding | Acceptance | Per destination SOP | Warehouse | Pallet execution |

A simple standard-and-remainder rule keeps packing lists audit-clean and prevents receiving count errors.

Receiving errors usually come from carton quantity drift: random remainders, mixed SKUs without disclosure, or carton marks that don’t match the packing list. A simple policy—standard pcs/ctn plus a remainder rule—keeps carton marks, packing lists, and warehouse counting aligned.

Carton Qty Policy

MUST

MUST NOT

OPTIONAL (only if allowed)

Boundary

If your warehouse forbids mixed cartons, carton qty rules must be single-SKU per carton—even if it creates more cartons.

The Real Freight Bill, For plush, volume often costs more than mass—stable unit pack and carton dims protect your freight budget.

Plush often pays for volume, not mass. Oversized cartons, inconsistent unit pack thickness, and last-minute compression changes can spike chargeable weight. Control comes from stable unit pack dimensions, carton dimension discipline, and “no change without recalculation” rules.

Quick Formula (Carrier-Dependent)

Air/Express: chargeable weight is usually the greater of

Actual weight vs Volumetric weight (L×W×H ÷ carrier divisor)

Ocean/LCL: cost often correlates with CBM, so carton volume and consistency still drive cost.

Practical Example (Same weight, different volume)

Carton A: 60×45×45 cm, GW 12 kg

Carton B: 55×40×40 cm, GW 12 kg

→ Carton B usually produces lower volumetric/CBM cost and better load efficiency.

Trigger Points (Where cost spikes happen)

Standard carton marks reduce receiving holds and make shortage/damage claims traceable.

Carton Mark Template

| Line / Field | Copy-ready format | Notes (rules) |

|---|---|---|

| PO / Program ID | PO: __________ | Match exactly to CI/PL |

| Style / SKU | SKU / Style: __________ | One main identifier |

| Variant | Variant: __________ | Color/size/version |

| Carton number | Carton No.: ___ / ___ | Sequential |

| Carton quantity | Qty: ___ pcs | Matches packing list |

| Net / Gross weight | NW / GW: ___ / ___ kg | One unit system |

| Carton dimensions | Dims: ___ × ___ × ___ (cm/in) | One unit system |

| Destination code | Dest Code: __________ | Only if used |

| COO (if required) | COO: __________ | Only if required |

Carton marks are operational compliance. A clean mark format reduces receiving friction, prevents mixed-SKU disputes, and makes shortage/damage claims traceable. Use the copy-ready template below so carton labels match packing list fields and scan consistently at receiving.

Copy the Carton Mark Template into your carton label/mark file. It’s designed for fast scanning, clean PL matching, and clear dispute resolution.

Placement Rule (Enforceable)

Related link: Labeling & Traceability

Execution Pack: Pallet Limits, Pre-Ship Check & Carton Plan Submission

If pallets are required, pallet height/weight rules must be known early so carton dims are designed to fit.

Palletization is not optional when the destination requires it. Ignoring pallet height/weight limits causes rework at port, 3PL, or DC. If pallets are required, pallet limits must be locked early so carton dimensions are designed to fit—not forced later.

When palletization is typically required

Pallet Spec Quick Card (Fields to lock)

Boundary

If pallet limits are hard constraints, carton dims and pcs/ctn must be designed around pallet footprint early.

A 2-minute checklist prevents dimension drift, remainder carton errors, and label/PL mismatches.

Most carton issues are predictable and preventable. Instead of “fixing mistakes,” run a short pre-flight check before packing starts. This prevents dimension drift, random remainder cartons, carton marks that don’t match packing lists, and late pallet constraints that cause rework.

Pre-Flight Carton Check

One formatted submission lets us return a usable carton plan without repeated back-and-forth.

Carton confirmation becomes fast when receiving rules are complete and formatted. Send the inputs below and we’ll convert them into a factory-executable carton spec sheet, carton qty policy, carton mark layout, and pallet plan (if required)—ready for packing execution and booking.

Carton & Pallet Input Pack

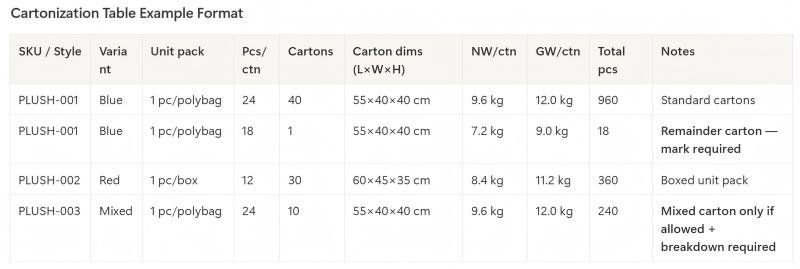

This table is the minimum dataset forwarders and warehouses need—built to match carton marks line-by-line.

This is the minimum cartonization table that prevents re-quotes and receiving disputes. It’s the packing data forwarders and warehouses actually need—structured so carton marks, packing list, and booking files match without interpretation.

Cartonization Table Example Format: please see the right picture

Packing Totals (Add below the table)

| Summary field | Value | Why it matters |

|---|---|---|

| Total cartons | ___ | Booking & receiving |

| Total pieces | ___ | Invoice & receiving |

| Total CBM (if available) | ___ | LCL cost & planning |

| Total GW (if available) | ___ | Freight planning |

| Palletization | Yes / No | Warehouse acceptance |

Quick Rules (Put as a short note)

Q1: Can cartons contain mixed SKUs?

It depends on your receiving SOP. Many retail DC programs prohibit mixed-SKU cartons. If mixed cartons are allowed, the carton mark must clearly disclose “mixed” and show a SKU-by-SKU breakdown that matches the packing list (and ASN if used).

Q2: How many label sides should we use?

If your warehouse scans cartons on arrival, two adjacent sides with consistent placement reduces receiving friction. Follow your warehouse rule first; the key is using one layout per shipment.

Q3: What’s a good max gross weight per carton?

Warehouses often cap carton handling weight. Use your destination SOP as the rule. If you don’t have one, set a conservative cap and keep it consistent so receiving and stacking remain stable.

Q4: When is palletization mandatory?

Often for retail DC and many 3PL routes, and sometimes depending on freight route. If pallets are required, pallet height/weight limits become hard constraints that cartonization must fit.

Q5: Do carton marks need to match CI/PL exactly?

Yes. Mismatches create receiving holds and make shortage/damage claims hard to verify. Treat carton marks and packing list fields as one synchronized dataset.

Avoid Carton Spec Failures Before You Ship

Lock carton specs early to protect freight cost, receiving acceptance, and claims clarity—without relabeling, repacking, or last-minute rebooking.

what breaks shipments?

How to lock it?

If you have questions or need a quote, leave us a message. We’ll reply within 12 hours with the best-fit solution for your requirements.

This form is built for accurate quoting—size, quantity, materials, accessories, and compliance needs. The more complete your brief, the fewer revisions and the faster your sample can start.

I am Nika, our team would be happy to meet you and help to build your brand plush.