At Uniomy, repeatable bulk results shouldn’t depend on luck. The factory system locks the right decisions early—specs, materials, construction, labeling, and acceptance rules—so the approved sample stays matched in production and every shipment arrives receiving-ready for smooth reorders.

Uniomy was established to bridge the gap between a design concept and a production-ready custom plush product. Built around a coordinated workflow—pattern engineering, materials selection, sampling, decoration craftsmanship, quality control, and mass production—each project is managed under one system to reduce revisions, control risk, and keep results consistent from sample to bulk.

Located in Guangdong, China, one of the world’s most mature manufacturing hubs, Uniomy benefits from supply-chain efficiency while meeting international expectations for quality standards, compliance awareness, and clear communication.

Clients served include global brands, agencies, importers, and e-commerce teams seeking stable execution: buildable specifications, consistent workmanship, and dependable delivery.

Built for repeatable programs.

Approvals stay consistent from sample to bulk.

Best for: Brand and IP teams that need shape accuracy, clear character identity, and reorder stability across runs.

Tags: Approval locking · Shape accuracy · Reorder stability

Listings scale with repeatable quality and packaging.

Best for: Sellers building a SKU that must stay consistent across replenishment cycles, including label/barcode and warehouse-ready packing.

Tags: Replenishment rhythm · Packaging rules · Defect control

Campaign plush stays brand-clear and scalable.

Best for: Marketing-led programs needing fast approvals, high logo readability, durable decoration, and stable output across multiple locations or timed drops.

Tags: Campaign timing · Brand clarity · Multi-location scale

Complex ideas become manufacturable plush.

Best for: Creative teams translating art into a sewable, repeatable build—balancing detail, softness, durability, and a realistic production route.

Tags: Feasibility-first · Pattern translation · Detail control

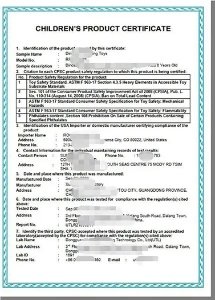

Safety readiness is built into execution.

Best for: Kids and education programs that require stable materials, consistent construction, and clear acceptance rules aligned to market compliance expectations.

Tags: Compliance readiness · Material stability · Safer builds

Deadlines stay protected with repeatable execution.

Best for: Campaign gifting and promotional programs needing readable branding, clean finishing, and packaging consistency for fast distribution and on-time arrival.

Tags: Deadline-driven · Logo readability · Pack-out accuracy

Souvenir quality holds up to heavy handling.

Best for: Attractions and entertainment brands needing durable builds, stable character likeness, and repeatable gift-shop readiness across seasonal restocks.

Tags: Durability · Character likeness · Restock-ready

Kitting stays accurate unit to unit.

Best for: Multi-item sets requiring inserts, barcode/label rules, checklist-based packing, and repeatable unboxing presentation across recurring waves.

Tags: Kitting accuracy · Checklist packing · Unboxing repeatability

Shelf-ready output stays consistent by batch.

Best for: Retail programs and channel launches that need uniform appearance, measurable acceptance rules, and predictable delivery for repeated drops.

Tags: Shelf consistency · Acceptance rules · Drop planning

A Controlled System From Sample to Scale

Classic stuffed animals built for repeatable bulk consistency and durable everyday handling.

Best for toy brands, e-commerce SKUs, and gift programs needing stable reorders.

Tags: Bulk consistency · Durable seams · Stable finishing

Character and doll plush with controlled proportions, facial placement, and stable finishing from sample to scale.

Best for IP teams, creative studios, and brands managing approval-heavy character builds.

Tags: Shape accuracy · Face placement · Version locking

Brand mascots and campaign plush designed for logo clarity, shelf impact, and reorder stability.

Built for corporate merch teams, promotional programs, and campaign agencies with deadlines.

Tags: Logo readability · Placement repeatability · Deadline planning

Pet plush toys built for higher pulling and chewing intensity with safer construction choices (project-dependent).

Built for pet brands and subscription programs needing durability and repeatable safety choices.

Tags: Pull resistance · Safer build rules · Durable seams

High-friction plush keychains built for reinforced attachments, durable decoration, and consistent placement.

Best for e-commerce and campaign giveaways where daily rubbing and pulling are expected.

Tags: Reinforced hardware · Wear durability · Placement stability

Plush pillows and cushions controlled for size, rebound feel, weight consistency, and clean edges.

Best for lifestyle brands and gifting programs that need comfort-driven repeatable bulk output.

Tags: Rebound feel · Weight range · Edge finishing

Interactive plush builds with stable electronics integration, safety-first assembly, and repeatable function checks.

Built for brands and promo programs needing sound/interaction features that remain reliable in bulk.

Tags: Function testing · Safety assembly · Stable integration

Wearable plush accessories designed for fit logic, comfort, durability, and repeatable sizing.

Best for brand merch and event programs needing wearable impact with consistent fit.

Tags: Fit sizing · Comfort lining · Reinforced stress points

Seasonal plush for launches and campaigns—optimized for deadlines, repeatable appearance, and packaging readiness.

Best for seasonal campaigns, retail programs, and promotional drops with fixed ship dates.

Tags: Deadline-driven · Repeatable look · Pack-out readiness

Blind box plush series managed for lineup consistency, variant control, and collectible-ready packaging.

Best for lifestyle brands and IP programs running multi-variant drops and reorders.

Tags: Variant control · Series consistency · Kitting accuracy

Yarn-based plush styles planned for stitch consistency, clean shaping, and repeatable finishing in production.

Best for designers and boutique brands that need handmade-look builds at scalable quality.

Tags: Stitch consistency · Shape control · Finishing stability

Realistic animal plush with controlled shape, fur direction, and detail readability that holds at scale.

Best for brands and attractions needing premium realism with stable bulk repeatability.

Tags: Fur direction · Detail clarity · Shape stability

Puppet plush with controlled openings, internal structure, and consistent movement-friendly construction.

Built for kids, education, and storytelling programs that require safe, durable interaction.

Tags: Opening control · Internal structure · Reinforced seams

Mini plush and hanging ornaments optimized for small-part stability, neat finishing, and packaging/kitting accuracy.

Best for blind boxes, gift sets, and seasonal drops needing clean, repeatable small builds.

Tags: Small-part control · Neat finishing · Kitting accuracy

Baby-safe plush builds with stricter material choices, construction rules, and risk-reduction priorities.

Built for baby brands and education programs that require safer builds and clear acceptance rules.

Tags: Safer materials · No-small-parts logic · Compliance readiness

Oversized plush with shape-holding structure, controlled stuffing zones, and packable bulk execution.

Built for events, mascots, and display programs that need scale without deformation.

Tags: Support zones · Weight control · Packability planning

Uniomy On-time delivery is protected by a control chain that prevents drift and rework: pattern → materials → stuffing/weight → sewing → decoration → packaging → AQL → needle/metal → capacity. Each link reduces surprises before they become schedule delays.

Bulk stays aligned when approvals become a locked reference—then every critical variable is controlled, not re-interpreted. Shape accuracy, material behavior, fill distribution, sewing routes, and decoration placement are stabilized so the approved look doesn’t drift as quantities scale. This reduces revision loops, prevents “first 200 pcs look good, next 800 drift” outcomes, and protects reorder consistency. The main process you can view:

Quality control works only when findings change production behavior immediately. Pass/fail rules are defined through measurable acceptance standards, and defects are classified consistently so decisions don’t vary by inspector or shift. When drift appears, containment, rework criteria, and re-check loops stop the same defect from spreading across the batch—and keep output inside the approved reference. Review the details:

Shipment readiness is more than packing—it’s repeatable execution. Packaging structure, inserts, labels/barcodes, kitting components, and carton marks must remain consistent unit to unit so warehouse receiving, shelf-ready delivery, and fulfillment flow without errors. Planning discipline also matters: bottlenecks are identified early, parallel workstations are planned, and second-check nodes protect timelines as volume ramps. Checking the control details:

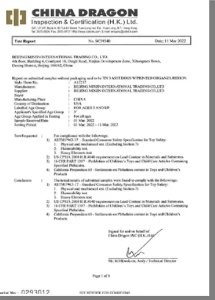

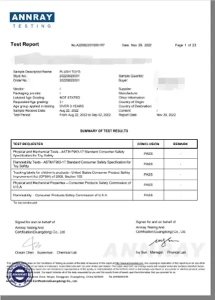

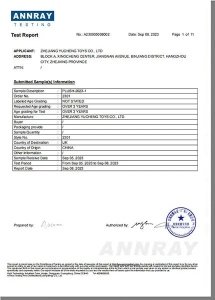

Trust is built through controls, not claims. Uniomy operates with a quality mindset designed for international buyer expectations—focusing on spec discipline, in-process checkpoints, and shipment readiness.

Quality system highlights often include:

AQL inspection options aligned to buyer requirements

QC gates across critical stages (materials → assembly → finishing → packing)

Needle/metal risk controls where applicable

Workmanship consistency checks for batch repeatability

Documentation readiness for approvals (photos, specs, packing marks, labeling references)

Certification availability can vary by project and destination market, but the operating principle remains: auditable process, consistent output.

Sustainability is treated as a practical, spec-driven decision—not a vague label. Uniomy supports brands seeking lower-impact material options and more efficient production planning while maintaining feel, durability, and commercial viability.

Sustainability support may include:

RPET / recycled materials options (fabric, stuffing) where suitable

Packaging reduction and kitting optimization

Material efficiency planning to reduce waste

Supplier documentation alignment when required by brand programs

The focus stays on what buyers actually need: credible material choices, consistent performance, and repeatable supply.

Trusted by Global Brands

Uniomy is built for long-term programs—where the goal isn’t a one-off sample, but a reliable product system that can grow. The long view prioritizes trend-aware creativity, engineering feasibility, and stable execution so product lines can expand without rework chaos.

A long-term partnership typically means:

Specs and build standards becoming clearer over time

Faster approvals through structured sampling checkpoints

Consistency improvements across repeat orders

Better cost and lead-time predictability with stable routing

The vision is straightforward: help brands scale plush lines with confidence—without losing design intent.

Verify Fast, Then Start With a Controlled Plan

If you need a plush factory you can trust on quality, timelines, and accountability—start here, and verify everything before you spend on sampling.

I am Nika, our team would be happy to meet you and help to build your brand plush.