Import isn’t “one-rule-fits-all.” Different markets and channels (3PL / retailer DC / e-commerce) may require different labeling, documentation, and compliance evidence.

The 4 preventable failure points (and how they’re backstopped):

Cooperate with Uniomy to help the process by Confirm → Lock → Align → Review → Ship, Control levers you can lock in 10 minutes:

Last updated: [Feb. 8th, 2026] · Applies to: custom plush shipments · Channels: 3PL / Retail DC / E-commerce (incl. FBA-like) · Use: non-legal coordination checklist

Import readiness depends on three inputs: what you’re selling (toy vs plush merchandise), where it’s going (market), and how it’s received (channel). This router tells you which checks are required and which checks are optional—so you don’t over-document or discover requirements after packing is locked.

If “yes”, tell broker before packing:

Output you should request (what “good” looks like):

Most clearance delays and disputes happen when responsibilities are assumed instead of assigned. This map clarifies who confirms what: IOR & broker own declaration and import clearance; warehouse/channel owns receiving and label rules; factory executes carton marks and document drafts based on the confirmed inputs.

RACI-style responsibility map (who owns what)

Legend: A = Accountable (final owner), R = Responsible (does work), C = Consulted, I = Informed

| Task / Decision | IOR (Buyer) | Customs Broker | Forwarder | Factory | 3PL / Retail DC / Channel |

|---|---|---|---|---|---|

| Import clearance & entry filing | A | R | I | I | I |

| HS/HTS code direction | A | R | C | I | I |

| Commodity description wording | A | R | C | I | I |

| Declared value & currency basis | A | C | I | I | I |

| Consignee/ship-to/notify party accuracy | A | C | I | I | I |

| Receiving labels, barcode formats, ASN/appointment rules | I | I | I | C | A/R |

| Carton qty rules + mixed-SKU policy | A | C | I | R | C |

| CI/PL drafts prepared from master table | I | C | C | R | I |

| Carton marks printed & matched to PL | I | I | I | R | C |

“Do not start packing until…” (control gate)

Brokers clear faster when they receive a clean package with complete declaration fields and consistent shipment data. This field table is the minimum dataset to avoid rework: HS/commodity description/value approach, consignee chain, SKU mapping, carton plan, and receiving rules. Confirm these before booking.

Minimum broker intake fields

A) Declaration fields (broker/IOR confirms)

B) Party fields (IOR provides)

C) Shipment fields (factory executes from locked master)

The fastest way to get held is a mismatch between Commercial Invoice, Packing List, carton marks, and the actual carton count. This system prevents interpretation: one locked master table drives CI/PL lines and carton marks, with fixed rules for carton numbering, mixed-SKU disclosure, and last-minute change control.

The “Single Source of Truth” rule

Lock one Cartonization Master Table that outputs:

Consistency rules

Quick self-check

The same shipment can clear customs but still fail receiving. Channels differ most on label formats, ASN/appointments, pallet rules, and mixed-SKU carton policy. Confirm these receiving deltas before printing labels or carton marks—so your packed cartons are receivable on arrival, not “held at dock.”

What must be confirmed before packing

| Receiving Item | 3PL Warehouse | Retail DC | E-commerce / FBA-like |

|---|---|---|---|

| Appointment / dock hours | Often required | Usually strict | Strict or platform-defined |

| ASN / pre-advice | Sometimes | Often required | Often required |

| Label format & placement | 3PL SOP-driven | DC compliance-driven | Platform-driven |

| Pallet requirement | Case-by-case | Common | Case-by-case |

| Mixed-SKU cartons | Often allowed if disclosed | Often restricted | Often restricted |

| Carton marks format | Flexible | Strict | Strict |

| Barcode type | Warehouse preference | Retail spec | Platform spec |

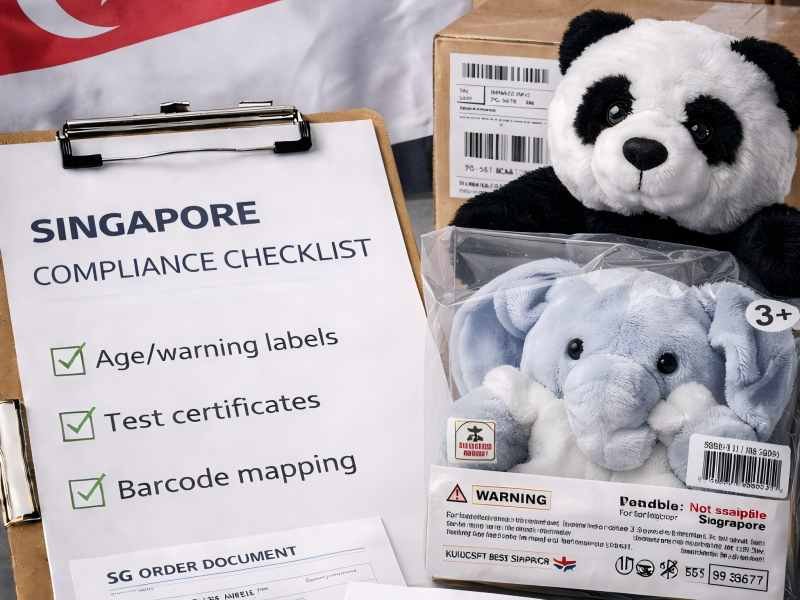

Most “import surprises” are not market-specific; they are execution failures (fields missing, documents inconsistent, receiving rules late). Use this section only to confirm what differs by destination market. Each market below lists three delta checks plus the typical avoidable hold pattern.

Important: final requirements are confirmed by your IOR/broker and channel for your SKU.

Confirm IOR + broker workflow and destination warehouse intake rules (owner: IOR/broker)

Confirm channel label/track rules (owner: channel/3PL)

Confirm mixed-SKU disclosure expectations (owner: channel + PL/carton marks execution)

Avoidable hold pattern: CI/PL/carton marks mismatch; carton numbering 1/xx not equal actual count

Confirm import/VAT workflow responsibility split (owner: IOR/broker)

Confirm whether toy-positioned SKUs need internal compliance evidence for approval (owner: channel/stakeholders)

Confirm label/traceability expectations for receiving/listing (owner: channel)

Avoidable hold pattern: incomplete consignee details across documents; late compliance scope confirmation

Confirm 3PL/DC receiving label rules early (owner: warehouse/channel)

Confirm Incoterms responsibility split (owner: buyer + broker)

Confirm carton marks format preferred by receiving warehouse (owner: warehouse)

Avoidable hold pattern: carton mark format rejected at receiving; PL not aligned with carton numbering

Confirm receiving label formats and appointment SOP (owner: warehouse/channel)

Confirm palletization requirement (owner: warehouse/route)

Confirm document pack scope if stakeholders require it (owner: buyer/channel)

Avoidable hold pattern: missing receiving labels; late packing changes after booking

Confirm broker workflow and required declaration wording (owner: broker)

Confirm whether stakeholders request toy safety evidence for child-use SKUs (owner: channel/stakeholders)

Confirm barcode/carton mark rules for receiving (owner: warehouse/channel)

Avoidable hold pattern: address fields inconsistent; PL/carton marks mismatch

Confirm age/warning display expectations for packaging and listing (owner: channel)

Confirm whether channel requests test evidence for toy-positioned SKUs (owner: channel/stakeholders)

Confirm SKU mapping + barcode placement rules (owner: channel/warehouse)

Avoidable hold pattern: missing warning/age info in listing/pack where required; mixed-SKU disclosure missing

Confirm destination country + channel workflow (owner: importer/broker)

Confirm whether conformity marking/evidence is required for toy category (owner: importer/channel)

Confirm label language + warning format expectations (owner: channel/importer)

Avoidable hold pattern: treating GCC as one market; evidence requested after packing is fixed

Most holds are not “customs surprises.” They are preventable operational errors: missing declaration fields, inconsistent documents, receiving rules confirmed too late, mixed-SKU cartons undisclosed, or carton plan changes after booking. Use the table below to diagnose the trigger and assign the correct owner to fix it fast.

| Preventable Hold Reason | Cause / Mismatch | Fix (one-time + prevention) | Owner |

|---|---|---|---|

| CI / PL / carton marks mismatch | SKU names, carton count, carton numbering 1/xx differs | Lock one master table; re-issue CI/PL drafts from same source; reprint carton marks | Factory executes; Buyer approves; Broker informed |

| Missing/unclear declaration fields | HS/commodity description/value approach not confirmed | Broker confirms HS/description/value basis; update CI descriptions; avoid marketing terms | IOR + Broker |

| Receiving rejection at dock | Label format/placement, ASN/appointment missing | Confirm receiving SOP before label printing; provide label proof and carton mark proof | Channel/3PL; Buyer coordinates |

| Mixed-SKU cartons undisclosed | PL does not match carton content | Explicit mixed-SKU disclosure rule in master table; align carton marks + PL notes | Buyer sets policy; Factory executes |

| Carton plan changed after booking | dims/weight/carton count changed late | Freeze carton plan before booking; if change required, re-issue booking + CI/PL + marks | Buyer + Factory + Forwarder |

Risk Triggers → Timeline → Broker Pack

Some plush programs trigger extra scrutiny or special handling. These are not problems—unless they’re discovered after packing is fixed. Use this list to surface risks early so your broker can confirm the correct declaration approach and your warehouse can confirm receiving requirements before labels and carton marks are printed.

Red-flag checklist

What to send when a trigger exists

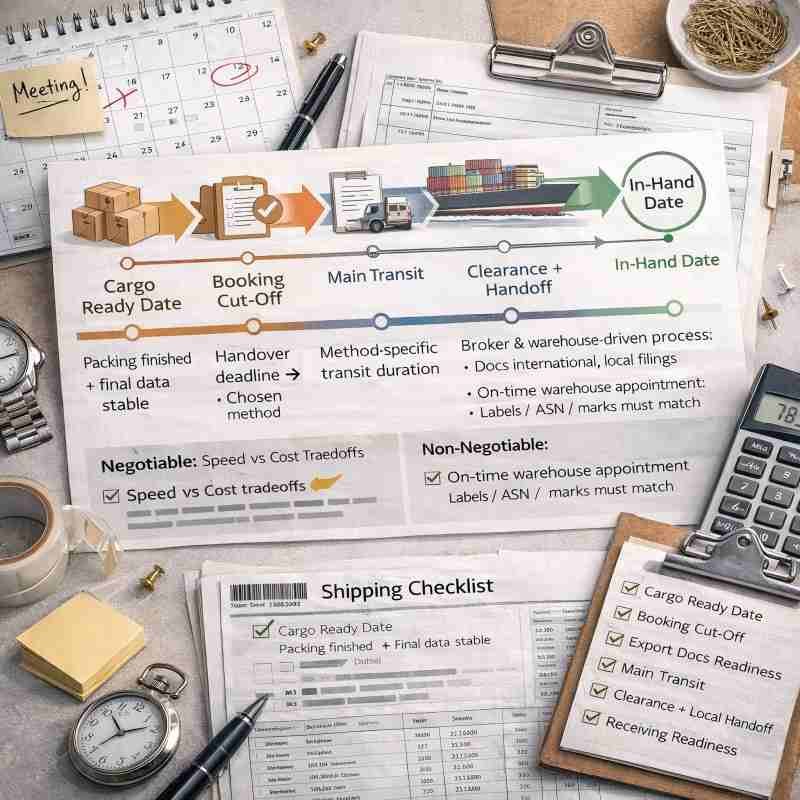

High-confidence importing is a timeline discipline. These checkpoints prevent last-minute rework: declaration fields confirmed early, receiving rules locked before labels, and final documents issued only after carton plan is frozen. Use this back-planning sequence to avoid changes after booking.

Recommended checkpoints to adjust to your program pace

T-21 to T-14 days: Broker confirms declaration fields (HS/description/value approach) + receiving rules requested

Deliverables: Broker intake sheet + draft CI/PL structure

T-14 to T-7 days: Carton plan frozen (pcs/ctn, dims, GW) + label formats locked

Deliverables: Cartonization master table + label proof

T-7 to T-2 days: CI/PL drafts finalized from master table + carton marks generated

Deliverables: Final CI/PL drafts + carton marks file

T-2 to T-0: Booking confirms totals; final file pack delivered to broker/forwarder

Deliverables: Broker-ready package (H2-11)

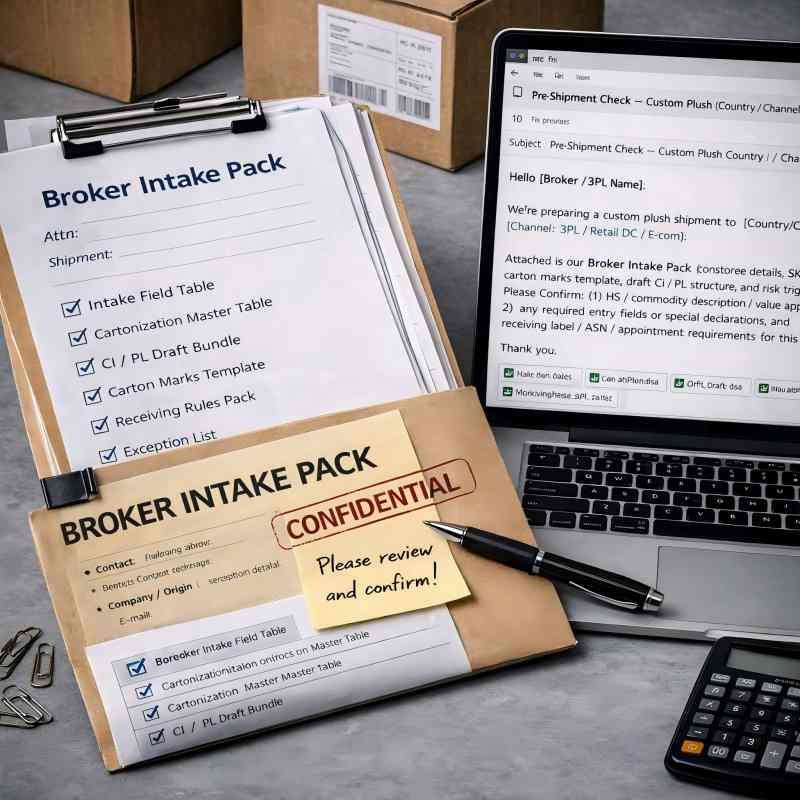

Brokers move fastest when they receive a complete, consistent package that matches the packed cartons. This broker-ready package reduces clarification loops, re-quotes, and receiving disputes. Request the templates below, then submit your destination + channel inputs to receive a formatted intake pack.

Broker-ready package contents

Subject: Pre-Shipment Check — Custom Plush (Destination + Channel + Intake Pack)

Body:

Hello [Broker/3PL Name],

We’re preparing a custom plush shipment to [Country/City] for [Channel: 3PL / Retail DC / E-com].

Attached is our Broker Intake Pack (consignee details, SKU list, carton plan, carton marks template, draft CI/PL structure, and risk trigger notes).

Please confirm: (1) HS/commodity description/value approach, (2) any required entry fields or special declarations, and (3) receiving label/ASN/appointment requirements for this destination/channel.

Thank you.

Q1: Is this page legal advice?

No. It’s a coordination checklist. Final import/compliance requirements are confirmed by your IOR, broker, and selling/receiving channel.

Q2: Do we always need compliance reports to import plush?

Not always. It depends on product positioning (toy vs merchandise), market, and channel/stakeholder requirements. The safest approach is to scope evidence needs before mass production finishes and packing is locked.

Q3: Can you work with our broker/forwarder?

Yes. Share the broker checklist and contact chain. Document drafts and packing data can be aligned to their preferred format to reduce rework.

Q4: What causes the most delays in practice?

Document inconsistency (CI/PL/marks), unconfirmed declaration fields (HS/description/value), and receiving rules discovered after labels are printed.

A complete, market-and-channel checklist plus editable templates that help your team and broker lock HS/commodity/value, keep CI/PL/carton marks consistent, and prevent the most common clearance and receiving holds—before packing is fixed.

What you will receive:

Best if you ship to 3PL / Retail DC / E-commerce, manage multi-SKU cartons, or have risk triggers (magnets/electronics/batteries/sets/oversize) and need a pack your broker can approve without back-and-forth.

If you have questions or need a quote, leave us a message. We’ll reply within 12 hours with the best-fit solution for your requirements.

This form is built for accurate quoting—size, quantity, materials, accessories, and compliance needs. The more complete your brief, the fewer revisions and the faster your sample can start.

I am Nika, our team would be happy to meet you and help to build your brand plush.