Picking the wrong shipping method doesn’t just change freight cost—it can miss your in-hand date and trigger warehouse receiving holds.

Simple definitions: Express / Air / Sea (LCL/FCL)

Choose air, sea, or express based on your deadline, order quantity, carton volume, and destination warehouse rules.

Last updated: [Feb. 8th, 2026] · Applies to: Express / Air / Sea (LCL/FCL) · Destinations: 3PL / Retail DC / E-commerce · Built for: custom plush shipments

This quick selector helps buyers choose a default shipping method using three inputs: in-hand deadline, shipment size/shape (carton volume), and destination receiving rules. Pick first, then validate with red-flag constraints and booking checkpoints to avoid re-quotes and delays.

Non-negotiable boundary: A “method recommendation” only becomes real when carton volume assumptions exist (even estimated).

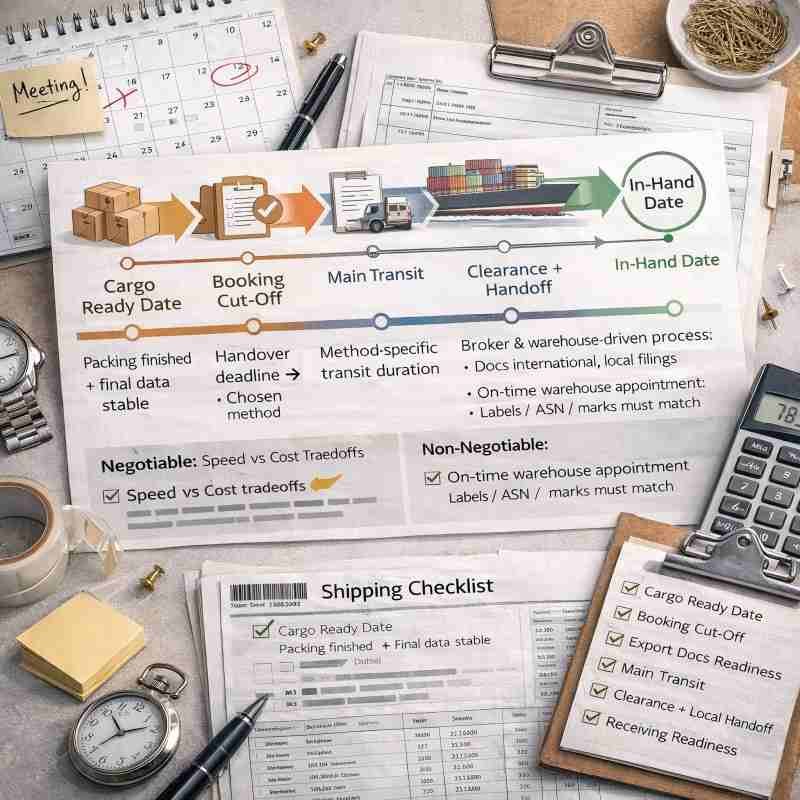

In-hand date = (cargo ready) + (handoff/cut-off) + (main transit) + (clearance/handoff) + (appointment-ready receiving)

Buyers miss launch dates because they plan for transit only. This module back-plans from your in-hand (receivable) date using booking cut-offs, doc readiness, clearance, and warehouse appointment rules—so “fast shipping” doesn’t become “arrived but not receivable.”

Confirm these timeline checkpoints:

Negotiable: speed vs cost tradeoffs.

Non-negotiable: receiving readiness (appointment + labels + docs) if you want “in-hand” to be true.

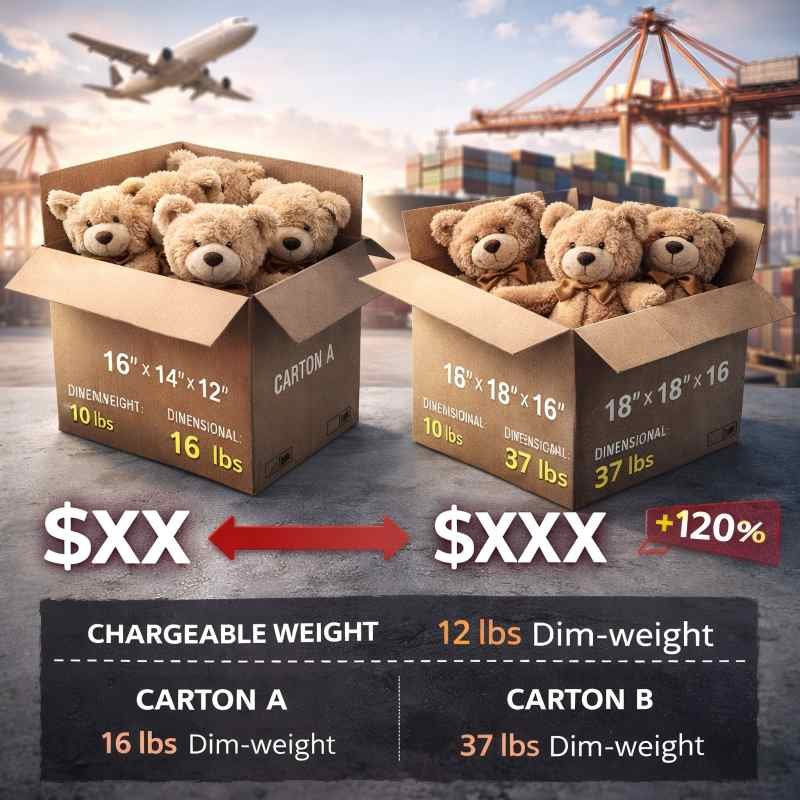

Chargeable Weight Reality of plush packaging.

Plush freight is priced by space more than weight. This module shows the cost mechanics that change real quotes: dim weight for air/express, CBM for sea, and destination handling rules. Use these levers early—before cartons lock an expensive outcome.

Cost mechanics

The 5 cost drivers buyers actually control

Dim-weight micro example

Two cartons can weigh the same physically, but one pays more if it’s bigger outside. For plush, puffy pack-out is the fastest way to inflate chargeable weight—especially on express/air. Check more Carton specs & palletization

Non-negotiable boundary: We won’t “optimize freight” after carton dimensions are already locked.

Chargeable Weight Reality of plush packaging.

Some constraints instantly change feasibility, cost, or routing. This red-flag list prevents wasted quoting loops and last-minute rebookings. If any item applies, method selection must include a constraint check—not just “air vs sea vs express.”

Red flags

What we do :

Related pages:

Chargeable Weight Reality of plush packaging.

Express is best for small urgent shipments (samples, replacements, micro-launch units). It is operationally simple but cost-sensitive to carton size. Success depends on compact pack-out, accurate consignee info, and consistent invoice/packing data.

Express — Buyer Card

Non-negotiable boundary: If cartons are bulky, express will be premium-priced by design.

Air freight is the typical choice when deadlines are tight but courier is uneconomical. It rewards preparation: stable packing data, consistent cartons, and receiving alignment. It also supports split shipping—air for launch quantity, sea for bulk.

Air Freight — Buyer Card

Negotiable: door-to-door vs airport-to-airport options (depends on destination).

Non-negotiable: packing data must be stable enough to book without rework.

Sea freight delivers the lowest unit cost for bulk plush when planned early. Choose LCL for moderate volume and FCL for high volume/control. Results depend on durable cartons, stacking logic, and destination receiving readiness—more than the ocean rate itself.

Related page: Carton specs & palletization

Non-negotiable boundary: Sea is not a last-minute rescue method; it’s a planning method.

Split shipment is the premium buyer strategy: ship a small launch portion by express/air and the bulk by sea. It protects launch dates while controlling margin—when separation rules on cartons and documents are visible and enforceable.

How split shipment works (3-step blueprint)

Where split shipments fail?

Non-negotiable boundary: Separation must be visible on cartons and on documents.

Beyond embroidery supply—an innovation system for consistent decoration.

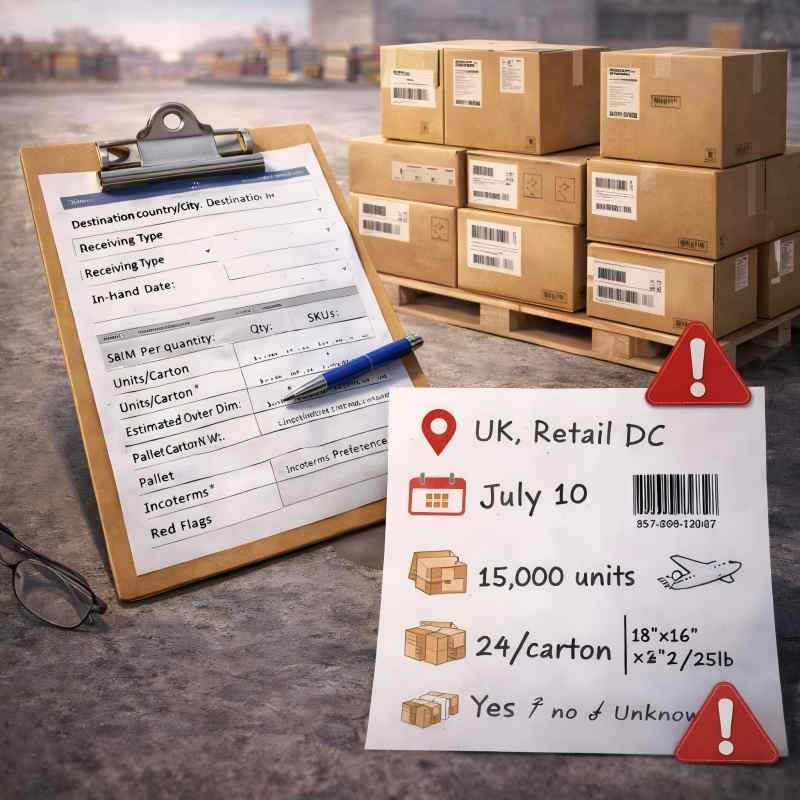

We can recommend the best method quickly

We can recommend the best method quickly when we know your in-hand date, destination receiving type, and carton volume assumptions. Send the inputs below and we return a method recommendation plus timeline checkpoints and a booking-ready checklist.

What you get back (deliverables-first)

Non-negotiable boundary: Outputs are assumption-linked—change carton assumptions → recommendation may change.

Q1: Which is cheaper—air or express?

For very small shipments, express can be operationally simple but not always cheaper. Plush is dim-weight sensitive; once cartons get bulky, air freight often becomes the better cost/speed balance for medium volume.

Q2: How can I reduce shipping cost for plush?

Control chargeable weight: reduce oversized carton volume, raise units/carton within weight limits, standardize carton sizes, and lock pack-out assumptions early. For hard deadlines, split shipment usually protects both timeline and margin.

Q3: Do Incoterms affect which method I should choose?

Yes. Incoterms decide who controls booking, risk, and paperwork. Lock scope early so “method choice” doesn’t collapse into responsibility confusion.

Choose Your Shipping Path — Get a Booking-Ready Recommendation

Pick a route below. Send 3 confirmations. We’ll return a method decision you can approve internally—aligned with carton volume, receiving rules, and document readiness (not guesswork).

Route A — Launch Fast (Express / Air)

Fastest in-hand path for urgent samples or launch-critical units—without dim-weight surprises.

Route B — Balanced Speed vs Cost (Air Freight)

A realistic deadline plan for medium volume—built around packing readiness and booking cut-offs.

Route C — Bulk Economics (Sea LCL / FCL)

Lowest unit cost for bulk programs—paired with pack-out durability and receiving readiness controls.

Route D — Protect the Launch (Split Shipment)

Launch quantity arrives fast, bulk stays economical—two-leg separation rules that prevent receiving confusion.

If you have questions or need a quote, leave us a message. We’ll reply within 12 hours with the best-fit solution for your requirements.

This form is built for accurate quoting—size, quantity, materials, accessories, and compliance needs. The more complete your brief, the fewer revisions and the faster your sample can start.

I am Nika, our team would be happy to meet you and help to build your brand plush.