Plush logistics is where cost and launch timelines are won or lost—dim-weight surprises, receiving holds, and document mismatches. This hub shows your next step and the exact inputs to lock cost, timeline, and warehouse acceptance before packing and booking.

Partner with uniomy in control levers

Tell us your destination, receiving type (3PL / Retail DC / E-com / FBA-like), and in-hand date. You’ll get a method recommendation, a back-planned checkpoint list, and a broker/warehouse-ready dataset that keeps CI/PL/carton marks/booking consistent.

Last updated: [Feb. 8th, 2026] · Applies to: Ocean / Air / Express · Receiving: 3PL / Retail DC / E-com / FBA-like · Best for: plush (dim-weight sensitive)

From 5 logistics situations, get the right guide, lock responsibilities, and prevent costly shipping failures.

Plush logistics becomes predictable when five blocks are aligned early: shipping method, Incoterms, carton rules, document consistency, and market/channel deltas. Miss one block and you usually get re-quotes, receiving holds, or disputes. Use the same system to scale reorders without reinventing the workflow.

The 5 blocks with direct links

Non-negotiables

Glossary Plush Logistics Terms

Most plush logistics failures are predictable: receiving rules weren’t locked, or the shipping method was chosen without carton assumptions. Use the matrices below to identify what must be confirmed before labels/packing/booking. Then route to the correct page to lock responsibilities, carton specs, and document consistency.

| Receiving type | Must confirm early (before labels & carton marks) | Failure if missed (what happens) | Route |

|---|---|---|---|

| 3PL (standard warehouse) | Dock hours + appointment SOP, label format, carton marking rules, pallet requirement (Y/N), max carton weight | Receiving pauses, relabeling request, re-measurement at dock | Carton specs & carton marks template+ Shipping documents checklist for plush |

| Retail DC | ASN requirements, SSCC/GS1-128 (if required), pallet pattern + height limit, carton label placement, compliance/packing rules | Chargebacks, DC refusal, forced relabel/repack, delayed put-away | Carton specs & carton marks template + Import notes by market & channel for plush shipments |

| E-commerce / DTC fulfillment | SKU/carton mapping, carton label/barcode, mixed-SKU carton disclosure rules, carton size limits, returns handling expectations | Mis-receive, inventory mismatch, slow inbound, claims disputes | Shipping documents checklist for plush + Carton specs & carton marks template |

| FBA-like programs | Polybag/label warning rules (if applicable), FNSKU/barcode logic, carton label format, carton count discipline, appointment/booking rules | Check-in delays, non-compliance tickets, relabel at cost, shipment split | Carton specs & carton marks template + Import notes by market & channel for plush shipments |

| Method | Best when | Primary cost driver | Risk trigger to declare early | What must be ready first | Route |

|---|---|---|---|---|---|

| Express | Hard deadline, small CBM, urgent replenishment | Chargeable weight (dim-weight) | Oversized cartons, lithium/battery, magnets, mixed SKUs | Carton dims/weights + label rules | Air vs Sea vs Express shipping methods for plush + Carton specs & carton marks template |

| Air freight | Deadline is tight but volume is controlled | Dim-weight + peak surcharges | Oversize cartons, DG items, routing cutoffs | Cartonization plan + CI/PL draft | Air vs Sea vs Express shipping methods for plush + Shipping documents checklist for plush |

| Sea LCL | Flexible timeline, mid volume, many SKUs | CBM + origin/destination handling | Late document alignment, receiving mismatch | Packing list mapping + carton marks consistency | Shipping documents checklist for plush + Carton specs & carton marks template |

| Sea FCL | Large volume, stable carton plan | Container utilization + local charges | Poor carton discipline wastes container space | Carton size standardization + pallet plan (if required) | Carton specs & carton marks template + Air vs Sea vs Express shipping methods for plush |

| Split shipment (Air + Sea) | Launch date is fixed but total volume is high | Air portion dim-weight + sea base cost | Wrong split ratio, late version changes | Tiered cartonization + back-planned checkpoints | Air vs Sea vs Express shipping methods for plush |

Non-negotiables that prevent rework loops

Lock carton volume (dim weight) and keep CI/PL/carton marks consistent to avoid cost spikes, clearance holds, and receiving delays.

Plush freight is often dominated by carton volume (dim-weight), not actual kilograms. Oversized cartons inflate air/express charges and trigger re-quotes. Most controllable savings come from carton discipline: standard + remainder rules, consistent dimensions, and marks that match the packing list line-by-line.

Buyer actions that cut cost

Simple “Cost control targets” rules

Go deeper: Carton specs & carton marks template

Most delays and disputes are document-consistency issues, not “customs surprises.” If CI, packing list, carton marks, and booking data don’t match, brokers ask questions, warehouses pause receiving, and claims become harder. Use the checklist to align drafts before dispatch.

The “match set” fields must match across files

The draft timing rule

Go deeper: Shipping documents checklist for plush

US/UK/EU/AU/MY/SG/GCC

Import expectations vary by destination and receiving channel. Our key market notes are a broker-ready operational checklist—not legal advice—so you can confirm what differs early and avoid holds caused by missing consignee details, inconsistent labels, or late compliance scoping.

What this section helps you prevent?

Go deeper: Import notes by market & channel for plush shipments

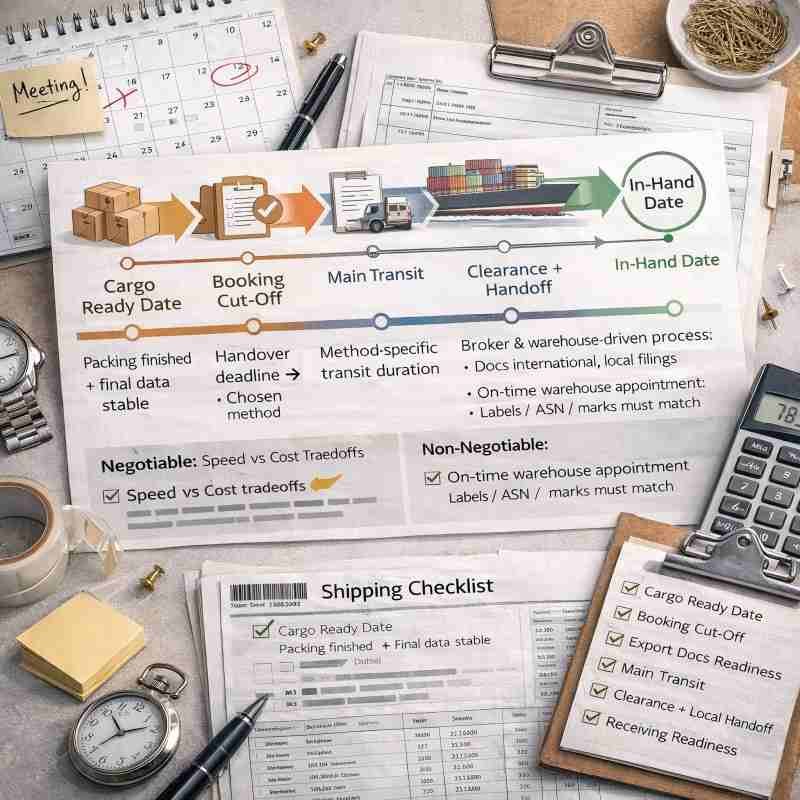

Work backward from your in-hand date, lock the right milestones, and use ready-made checklists to move without rework.

Logistics works when dates are back-planned from your in-hand receiving deadline. Confirm receiving type and Incoterms first, then lock carton specs and labels, align CI/PL drafts, and only then finalize BL/AWB with your forwarder. This sequence prevents rework loops and missed cutoffs.

Simple Repeatable Back-planned flow

Checkpoints that prevent “re-measurement + relabel” pain

If you want speed, start with templates. These formats reduce back-and-forth and help your broker/forwarder and warehouse move faster because information is consistent. Request the pack and we’ll share the editable formats matched to your shipment type and destination.

Templates included

What we need from you?

Q1: Can you recommend the best shipping method for my plush order?

Yes. Share destination, in-hand date, quantity tiers, SKU count, and carton assumptions. We’ll reply with a method recommendation (air/sea/express or split) plus the back-planned checkpoints your team can follow.

Q2: What delays plush shipments most often?

Most delays come from document mismatch (CI/PL/carton marks/booking data) and late confirmation of receiving rules. Align drafts before dispatch and lock label/ASN/appointment requirements before printing labels.

Q3: Do I need pallets?

Only if your 3PL/retailer/DC requires it. Confirm pallet size, max height, wrap rules, and label format early—so carton dimensions are designed to fit instead of being forced later.

Q4: Do you provide import advice for every country?

We provide operational coordination checklists for key markets to reduce preventable holds. Final legal/compliance requirements must be confirmed by your IOR and customs broker for your SKU and selling channel.

Most “logistics surprises” come from predictable gaps: DIM-weight carton drift, receiving rules locked too late, and CI/PL/carton marks mismatch. Send your shipment details and we’ll return a risk-action checklist that locks these before booking.

Share your:

If you have questions or need a quote, leave us a message. We’ll reply within 12 hours with the best-fit solution for your requirements.

This form is built for accurate quoting—size, quantity, materials, accessories, and compliance needs. The more complete your brief, the fewer revisions and the faster your sample can start.

I am Nika, our team would be happy to meet you and help to build your brand plush.