Make sampling predictable: clear sample types, measurable review points, and structured revisions—so your team can approve faster and move to production with confidence.

Uniomy’s controlled custom plush sampling system resolves the biggest risks before prototyping:

“feels different” → swatch baseline

“color looks off” → one approval standard

“revision drift” → structured rounds

Sampling turns your idea into a risk-tested, market-ready product before any scale investment is made.

Sampling turns your design into an approved reference that bulk production must match—so output stays consistent from the first unit to the last.

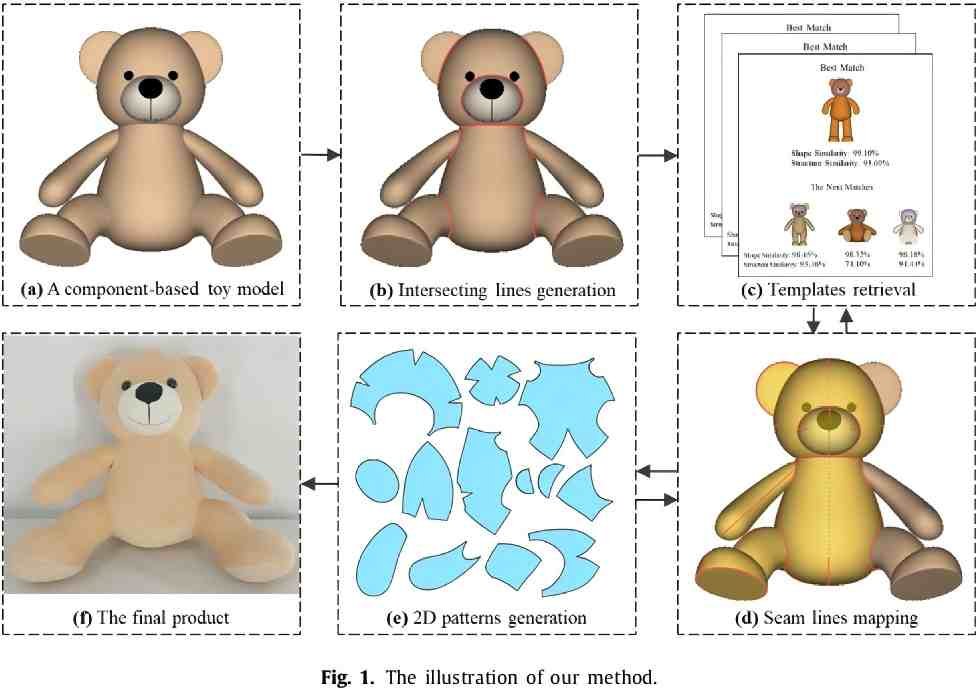

A sample proves the plush can be built as intended: pattern pieces, seam paths, proportions, and assembly steps are workable before you scale.

Sampling confirms the visual targets—face shape, silhouette, proportions, and character features—so approvals are based on clear, repeatable details.

A sample lets your team approve the hand feel, pile height, and pile direction/sheen behavior that can change how the plush looks on camera and in hand.

Sampling locks logo/patch/label placement using measurable anchors (distance to seams, centerlines, zones), preventing “looks shifted” disputes in bulk.

Sampling defines what “approved” means: PP sample / golden reference becomes the benchmark for QC, reorders, and repeatability—so production isn’t based on interpretation.

When sampling has a clear goal (structure, feel, placement, consistency), feedback becomes actionable, revisions stop drifting, and approvals happen faster.

Sampling turns vague comments (“cuter”, “softer”) into specific change requests—dimensions, fabric selection, placement rules—so the next round fixes the right things.

Sampling is not “making one perfect piece.” It’s locking a repeatable standard your production can follow.

Choose one path to reduce revision rounds and cost.

Idea Stage → Concept Sample → Revised Sample

Best for: first-time designs, new characters, unclear structure, complex shapes

Outcome: confirm feasibility and direction before polishing details

Launch Stage → Photo Prototype → Final Approval

Best for: e-commerce listings, marketing shoots, brand reveal deadlines

Outcome: camera-ready look, branding clarity, and finish standard

Production Stage → PP Sample / Golden Sample → Mass Production

Best for: reorder programs, tight timelines, compliance-sensitive markets

Outcome: production-ready baseline for bulk consistency and repeat orders

3 workfolw from Sample Types, Revision Timeline & Input Checklist

Each sample has one job—so approvals stay clean.

Sample types are faster to approve when each has a clear purpose: concept, structure validation, photo prototype, PP sample, and golden sample. This overview helps your team know exactly what they are approving—and links to the full milestone guide for detailed expectations.

Common Confusion:

PP sample proves production readiness; golden sample locks the final reference standard used to judge bulk.

Predictable rounds beat unpredictable resets.

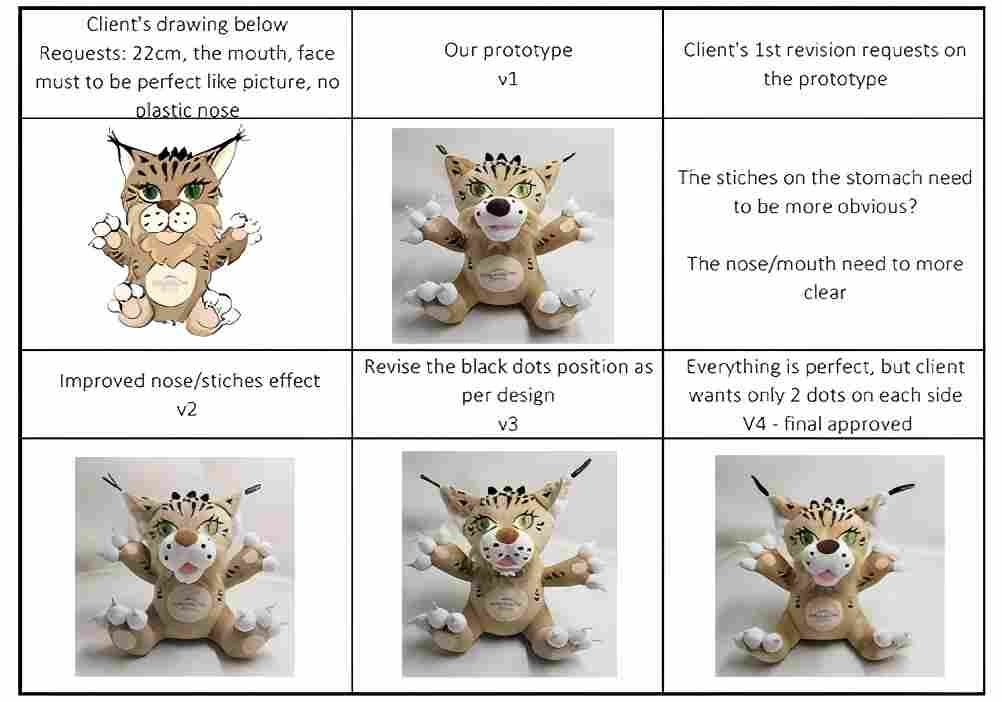

A typical custom plush sampling cycle follows V1 → feedback → V2/V3 → approval. Timing depends on input completeness, material stability, and how feedback is consolidated. This section summarizes common delay triggers and links to the full sampling timeline and revision rules.

Typical expectation:

What most impacts timeline and revision rounds:

Clear inputs remove guesswork and reduce revisions.

You don’t need perfect specs—but you do need clear inputs to start custom plush sampling smoothly. A structured “what to provide” checklist helps align size, market, materials, branding placement, and packaging expectations. It also flags feasibility and compliance risks early to prevent rework.

Minimum inputs to start:

High-impact inputs (often save a revision round):

Fabric decisions :

If your risk is “feels different” or “color looks off,” lock fabric early with a Fabric Swatch Pack—confirm hand feel, pile length, thickness, sheen direction, and color standard before prototyping.

Measurable review points create actionable feedback.

Fast approvals come from a measurable sample review framework: dimensions, proportions, placement, hand feel, attachments, and finishing. When feedback is quantified, revision rounds don’t drift and the approved sample becomes a stable production baseline—especially across multiple internal stakeholders.

Use this review checklist to keep feedback clear:

How to submit feedback : one consolidated feedback list per round to avoid conflicting edits and timeline resets.

One click routes you to the fastest sampling path.

Start based on what you already have: artwork ready, photo-ready needs, production approval, or fabric decisions not yet locked. This quick selector routes you to the right guide page—so you avoid wasted rounds and move from sampling to production with confidence.

I am Nika, our team would be happy to meet you and help to build your brand plush.