Sampling is not “try and hope.” Our in-house sample room runs on an iteration system: measurable reviews, version control, and approval records—so your prototype becomes a repeatable production standard.

Sampling turns your idea into a risk-tested, market-ready product before any scale investment is made.

lead time clarity

early issue detection

fewer revision cycles

launch timeline protection

deadline reliability

cost driver visibility

material cost control

construction complexity awareness

rework avoidance

budget predictability

visual appeal testing

hand-feel evaluation

proportion accuracy

sell-through confidence

buyer feedback readiness

buildability validation

structural integrity review

attachment risk identification

process limitation awareness

scalability assurance

workmanship standards

inspection reference sample

batch consistency baseline

repeat-order stability

quality expectation clarity

faster internal approvals

clearer decision criteria

reduced back-and-forth

licensor / partner alignment

smoother communication flow

This is the cornerstone of the bridge between excellent design and successful product.

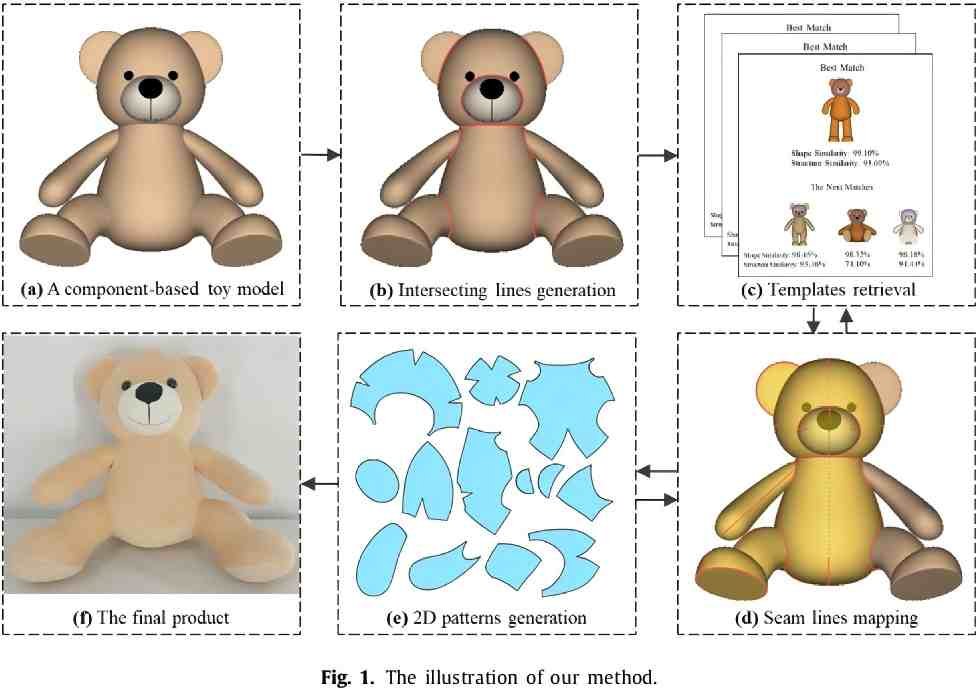

5 structured sampling workflow that turns ideas into buildable, reviewable, and production-aligned samples—without guesswork or endless revisions.

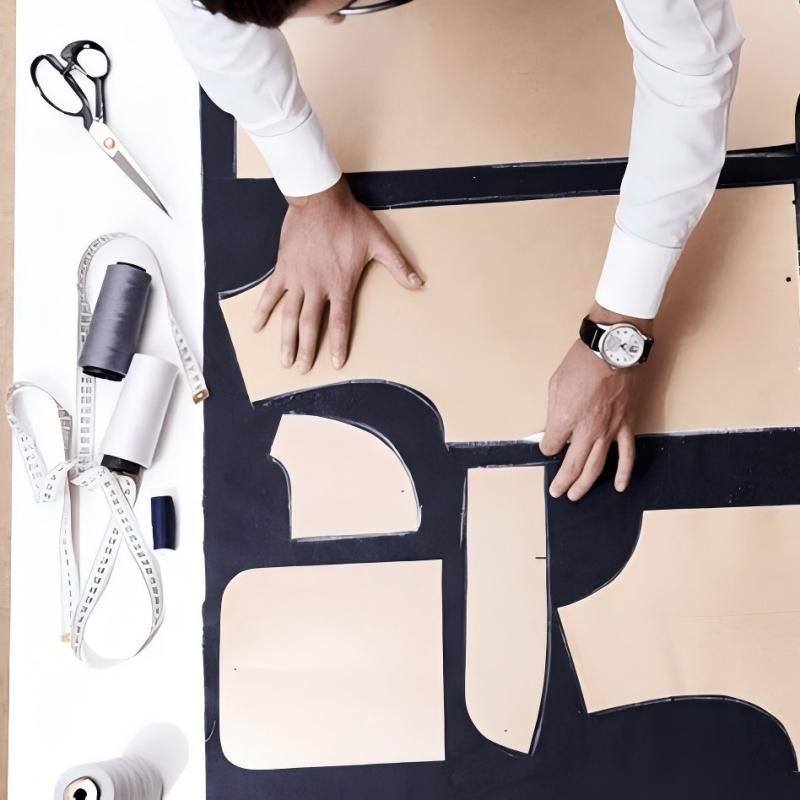

Workstations Inside the Sample Room

Dedicated workstations are used for patterning, cutting, sewing, detail work, stuffing and shape control, and finishing. The goal is consistent execution across revisions—so later sample rounds stay true to the approved structure.

Sample workfollow:

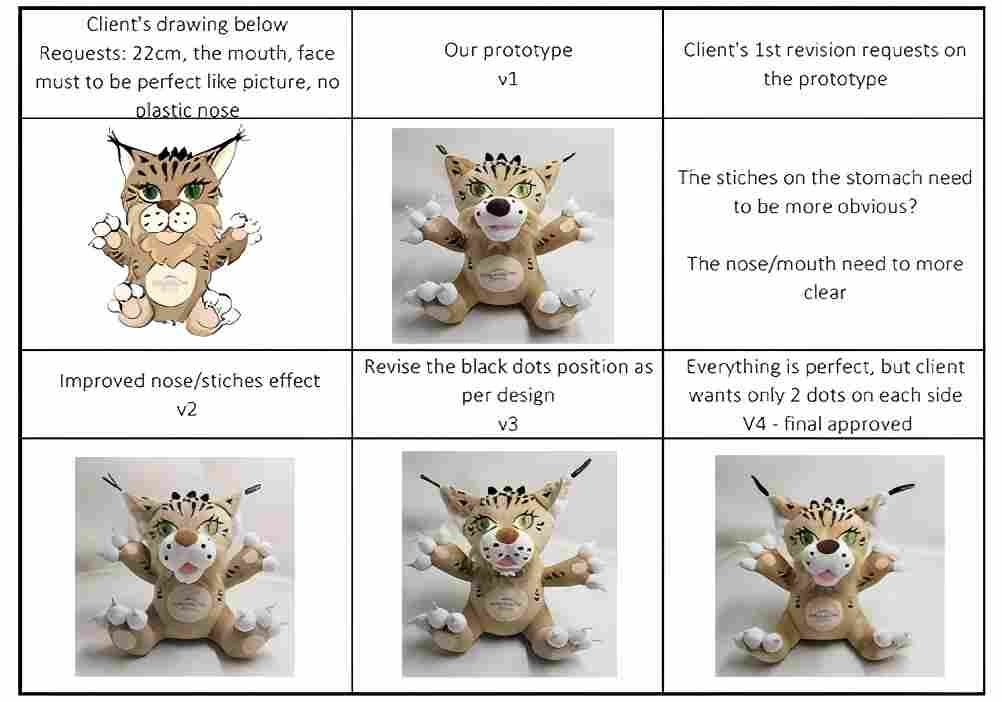

Iteration Rounds: Version, Not Chaos

Revisions are normal—chaos is not. We use clear rounds and version references so your team can review, decide, and move forward. Each round focuses on specific priorities: structure first, then finishing, then production readiness.

Review Standards: So “Approved” Is Measurable

Approval is faster when review standards are clear. We review samples against measurable checkpoints—size points, proportions, symmetry, branding placement, feel targets, accessory function—so feedback is actionable and results improve round by round.

Common review checkpoints (project-dependent):

Deliverable mindset:

Feasibility & Engineering Notes

Complex plush needs engineering decisions: standing/sitting stability, thin parts that collapse, heavy embroidery areas, or late accessories. We document feasibility notes and propose structure options so you choose tradeoffs early—before costly rebuild rounds.

Typical hard problems:

Sample Lock Confirmation: Final Sample Approval

A production program needs a locked reference. The production-ready sample is where size, branding placement, material feel, and workmanship standards are finalized—giving both production teams and QC a single, objective reference to follow.

Faster Decisions, Fewer Revisions

Speed comes from clarity. When inputs are complete and decisions are structured, revisions shrink. We provide guidance to make your sampling faster: artwork readiness, reference samples, and a “decide-first” checklist for brand teams.

What helps samples move faster:

What causes delays and rework:

These patterns are common across slow projects—and easy to avoid with upfront clarity.

Consistent Bulk Output, No Sample Drift

A sample only matters if bulk production matches it. Clear production references—photos, measurements, placement rules, and quality checkpoints—ensure sewing lines and QC teams reproduce the approved sample consistently, instead of guessing once production begins.

What keeps bulk production aligned with the approved sample:

These controls help prevent common issues such as shape drift, logo misplacement, and inconsistent hand-feel between batches.

Q1: Do we need perfect specs to start?

No. Artwork + target size + use case is enough for feasibility review. Clear priorities help the first round land closer to your expectations.

Q2: How many rounds are typical?

It depends on complexity and how consolidated feedback is. Our goal is to solve structure early, then refine details, then lock production reference at PP/golden stage.

Q3: Can we speed up sampling?

Usually yes—by locking size early, avoiding late material/accessory changes, and giving consolidated review feedback with clear priorities.

Q4: What will you share as documentation?

We can share redacted checklist snapshots, change log examples, and photo comparisons as needed for internal approvals.

Q5: How does sampling affect lead time?

Sampling decisions protect production lead time by preventing rebuilds and late rework. It also defines a clear reference for QC and line execution.

Verify First, Then Move Forward With Confidence

Request a tour pack or share your project essentials. You’ll receive feasibility notes, a clear sampling plan, and review-ready references for internal approval.

I am Nika, our team would be happy to meet you and help to build your brand plush.