Quality Controls That Catch Issues Before Bulk Ships.

Quality is protected by staged checkpoints—materials, in-process execution, finished goods, and outgoing readiness—plus AQL-based acceptance at the release gate when required. The goal is simple: fewer defects, fewer surprises, and shipment-ready consistency backed by clear records and IP-safe proof snapshots.

Checked by stages. Released with proof.

Quality control is structured as staged checkpoints—so issues are found early, corrected fast, and verified before shipment. Coverage spans materials, production execution, final acceptance (AQL-based when required), and outgoing readiness.

Coverage includes:

What this coverage prevents (buyer-visible failures)

Quality coverage is built to stop defects early—and ship with confidence.

Inspect by triggers. Correct fast. Re-check.

Match the decoration method to artwork type, plush size, fabric texture, and end use. This section maps each option to the most stable outcome—logo readability, face expression, color coverage, and durability—so the project stays clear and consistent from sample to bulk.

Inspections run on triggers—not on memory. Common triggers include:

A finding triggers an action—never “let it slide.”

Inspection runs as a control loop—so bulk stays inside the approved standard.

Visible Failure Modes Before Shipping

Checks are organized around buyer-visible failures—the issues that show up in photos, unboxing, handling, and receiving. Each category follows the same logic: risk → checkpoints → recorded outputs.

Risk:open seams, broken stitches, uneven panels, visible misalignment that degrades appearance and durability.

Checkpoints:high-stress seams, edge binding areas, seam intersections, symmetry/shape alignment at key landmarks.

Recorded outputs:defect type + location notes, cropped seam photos for repeat issues, rework/hold decision log.

Risk:under/over stuffing, uneven firmness, leaning shapes, inconsistent weight/hand-feel across units.

Checkpoints:shape profile against reference, firmness balance across key zones (head/body/limbs), weight range consistency when specified.

Recorded outputs:shape/feel notes vs approved reference, out-of-range flags, rework actions and re-check confirmation.

Risk:blurred edges, merged lines, blocked letter openings, drifting placement, inconsistent scale across batches.

Checkpoints:logo/face clarity at normal viewing distance, thumbnail readability, placement alignment to reference landmarks (centerline/eyeline/seams).

Recorded outputs:cropped close-ups (IP-safe if needed), placement confirmation snapshots, drift flags and corrective actions.

Risk:loose accessories, weak stitching points, detachment risk during handling, inconsistent attachment placement.

Checkpoints:attachment points, seam reinforcement areas, pull-risk zones (loops, straps, keychains), consistency of placement and orientation.

Recorded outputs:attachment check notes, defect photos for failure modes, isolate/rework records and post-fix re-check result.

Risk:missing inserts/accessories, incorrect barcode/label, mixed variants, carton rule mismatch that causes receiving delays.

Checkpoints:pack-out BOM match, label template match + placement rule, SKU zoning verification, carton count and packing list alignment.

Recorded outputs:pack-out verification snapshots, checklist tick records (template style), random carton-check photos (redacted if needed).

Checks focus on visible failure modes—so bulk stays brand-ready and verifiable.

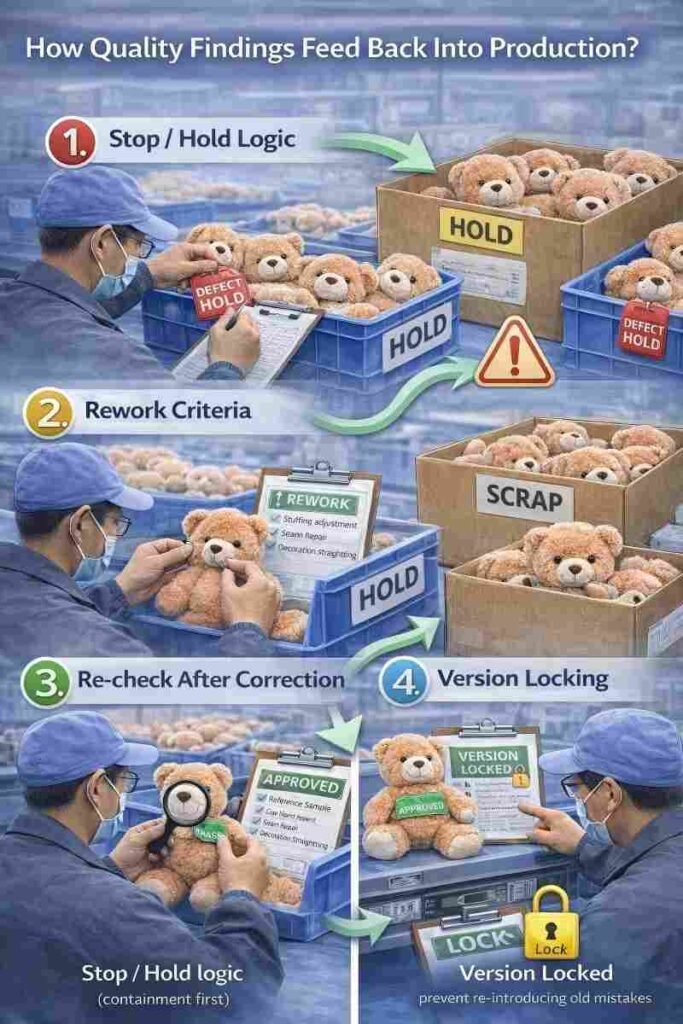

Find. Hold. Fix. Re-check. Lock.

Quality control only works when findings change production behavior immediately. This module shows the corrective loop that prevents the same defect from repeating across the batch—and keeps bulk output inside the approved reference.

Stop / Hold logic (containment first)

Rework criteria (fixable vs non-fixable)

Re-check after correction (proof of recovery)

Version locking (prevent re-introducing old mistakes)

Risk controlled, evidence shown.

Q1: What’s the difference between QA and QC?

QC is how defects are found and contained on the floor. QA is the documented system that keeps those checks consistent and auditable across batches.

Q2: Do AQL inspections apply to the whole process?

AQL is typically used for final/outgoing acceptance decisions on a lot. Earlier checkpoints (incoming and in-process) prevent drift before it reaches the release gate.

Q3: Do you support AQL inspections?

Yes. AQL sampling can be planned to match program requirements, with internal pre-checks and optional coordination for buyer or third-party inspections.

Q4: How are defects defined and judged consistently?

Defects are classified (critical/major/minor) and judged against the approved reference plus project-specific checkpoints—so decisions stay consistent across operators and lots.

Q5: How is consistency maintained across batches?

Execution and inspection criteria are tied to the approved reference, locked checkpoints, and release-gate verification—so bulk output stays inside the same standard.

Fewer defects. Clear release decisions.

Send product specs, target market/channel, and your top risk concerns to map an inspection setup: staged checkpoints, defect judgement rules, and an AQL-based release gate when required. Get verifiable outputs—inspection summaries and IP-safe photo evidence—so shipment quality is auditable, not assumed.

I am Nika, our team would be happy to meet you and help to build your brand plush.