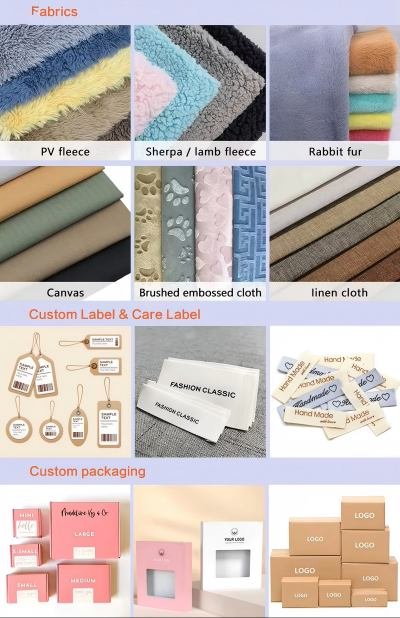

Many plush issues start with materials—looks right, feels wrong, or changes between batches. This fabrics and materials lab is built to verify fabric options, hand-feel targets, and batch consistency, so approved samples can be reproduced reliably in production.

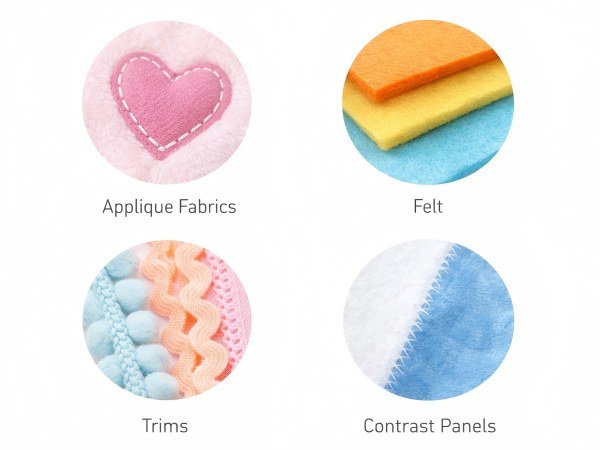

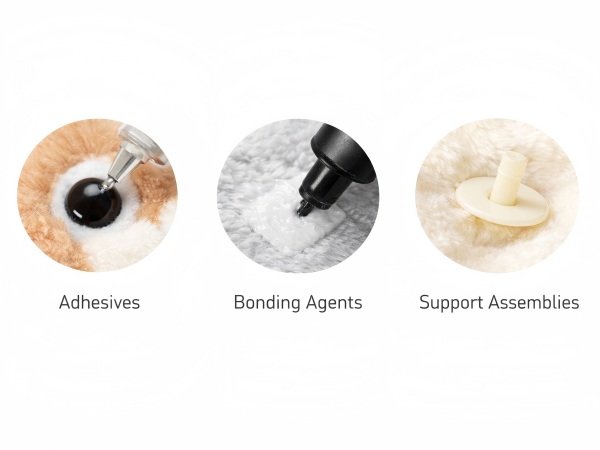

A complete view of materials—not just surface plush.

Primary Materials — Define Look & Hand-Feel

The main exterior material that defines first impression

Used for outfits and soft garment components

Supporting Materials — Define Structure & Durability

Hidden materials that support surface stability

Materials that support pose, load, and attachment points

Materials that define weight, firmness, and form

Detail & Assembly Materials — Define Finish & Reliability

Materials that enhance visual identity

Often overlooked, but critical for durability

Used when stitching alone is insufficient

Turn “soft enough” into a repeatable standard. Define feel once. Repeat it every time.

Hand-feel is not subjective guesswork. It is defined, referenced, and controlled. This lab aligns fabric choice, pile direction, filling behavior, and assembly handling so the approved sample’s softness, firmness, and rebound can be reproduced consistently across sampling rounds and production batches.

How hand-feel is defined at the sample stage

Hand-feel is clarified before sampling begins, not adjusted randomly afterward.

This prevents vague feedback like “softer” without a clear baseline.

What factors actually affect hand-feel

Hand-feel is the result of multiple material and process variables working together.

No single material determines feel on its own.

How consistency is maintained from sample to bulk

Once hand-feel is approved, controls are applied to prevent drift.

This reduces batch-to-batch variation and unexpected feel changes.

What typically causes hand-feel variation (and how it’s avoided)

Common causes of inconsistency include:

These risks are addressed before production, not after complaints.

What you gain from controlled hand-feel

Catch material problems before they reach sampling or sewing.

Material issues are cheapest to fix before cutting begins. Incoming inspection screens surface fabrics, supporting materials, and fillings against defined acceptance ranges—so color shifts, feel variation, or structural risks are identified before they affect samples or bulk production.

What is checked at incoming stage

Incoming materials are reviewed against project-specific requirements, not generic standards.

Only materials within acceptable ranges move forward.

Why incoming checks matter for plush projects

Many plush quality problems originate before production starts.

Incoming inspection prevents these issues from reaching sampling or sewing stages.

How non-conforming materials are handled

Materials that fall outside defined ranges are not forced into use.

This avoids downstream rework and sample inconsistency.

What buyers gain from incoming inspection control

Control variation before it reaches bulk output.

Batch variation is a reality, not a surprise. This lab manages acceptable ranges for color and hand-feel, aligns new batches to approved references, and flags risk before use—so repeat orders remain visually and tactually consistent.

Why batch variation happens in plush materials

Even when materials share the same name, batches can differ.

Without controls, these differences surface late—after cutting or sampling.

How acceptable ranges are defined

Consistency does not mean “identical,” but within agreed limits.

Materials outside range are reviewed before use.

How new batches are aligned to approved samples

When a new batch arrives:

This prevents silent drift across repeat orders.

What happens when variation exceeds tolerance

If variation cannot be aligned:

Decisions are made early, not after bulk production begins.

What you gain from batch variation control

Stable materials make scalable production possible.

Repeatable production depends on controlled materials. When fabric options, hand-feel targets, batch tolerances, and incoming checks are aligned early, approved samples translate into stable bulk output—without last-minute adjustments, quality drift, or unexpected rework.

Why fabric control matters beyond sampling

Materials that are not controlled at the start rarely become stable later.

Fabric control sets the foundation before production pressure begins.

How fabric decisions flow into production execution

Once materials are aligned:

Production teams execute standards instead of compensating for variation.

What this prevents during scale-up

Most scale-up failures trace back to uncontrolled materials, not workmanship.

How this connects to other factory systems

Fabric control keeps these systems aligned.

What buyers gain from repeatable fabric control

Q1: Can you recommend fabrics if we don’t know fabric names?

Yes. Tell us the look/feel goal, usage scenario, and target market. We’ll recommend suitable options and confirm during sampling.

Q2: Why does the same fabric look different in photos?

Pile direction and lighting can change perceived color and shading. We manage cutting orientation and alignment to reduce this effect.

Q3: Can you match a specific Pantone color exactly?

We can align to a color reference and reduce variation through early confirmation and batch notes. Exact matching depends on fabric type and supplier conditions—best evaluated early.

Q4: Do recycled fabrics feel different?

Sometimes. We can propose options and help balance feel, durability, and documentation expectations (e.g., recycled content requirements).

Q5: Can you provide material documentation?

We can support documentation paths based on program needs and supplier availability (project-dependent).

Clarity first. Fewer surprises later.

Before sampling or scaling, confirm that fabric options, hand-feel targets, and batch consistency are aligned. Share your product basics or request a material overview to review control points, risks, and next steps—without committing to production.

I am Nika, our team would be happy to meet you and help to build your brand plush.