Plush designs don’t fail in production by accident.

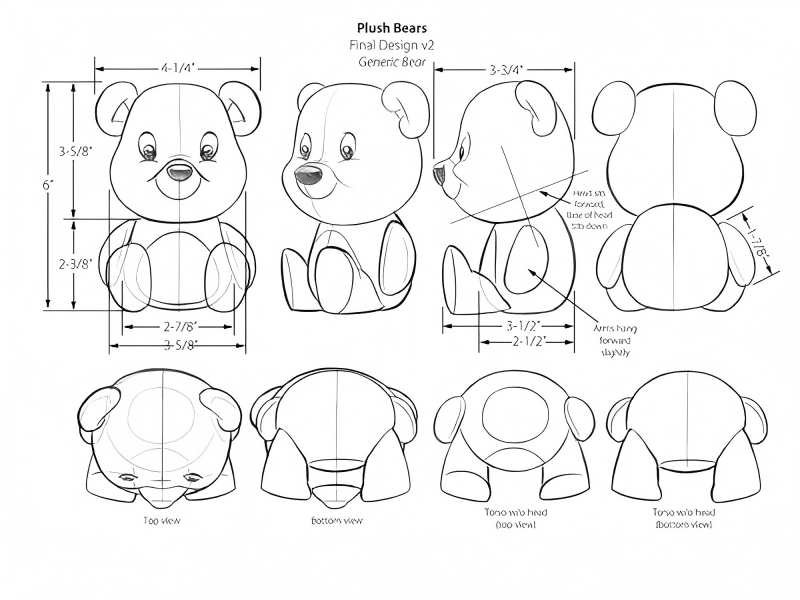

Pattern engineering determines whether shapes hold, proportions stay consistent, and attachments remain stable—especially for complex silhouettes and multi-part characters.

Pattern engineering addresses the structural risks that artwork alone can’t resolve.

Whether shapes are feasible as drawn

Areas that require simplification

Construction risks before sampling

Limits of handcraft vs mass production

Panel breakdown logic

Seam placement and joining order

Distortion risk at curves and joints

Shape stability after stuffing

Head / body / limb ratio control

Symmetry across left and right sides

Proportion consistency across sizes

Visual balance after assembly

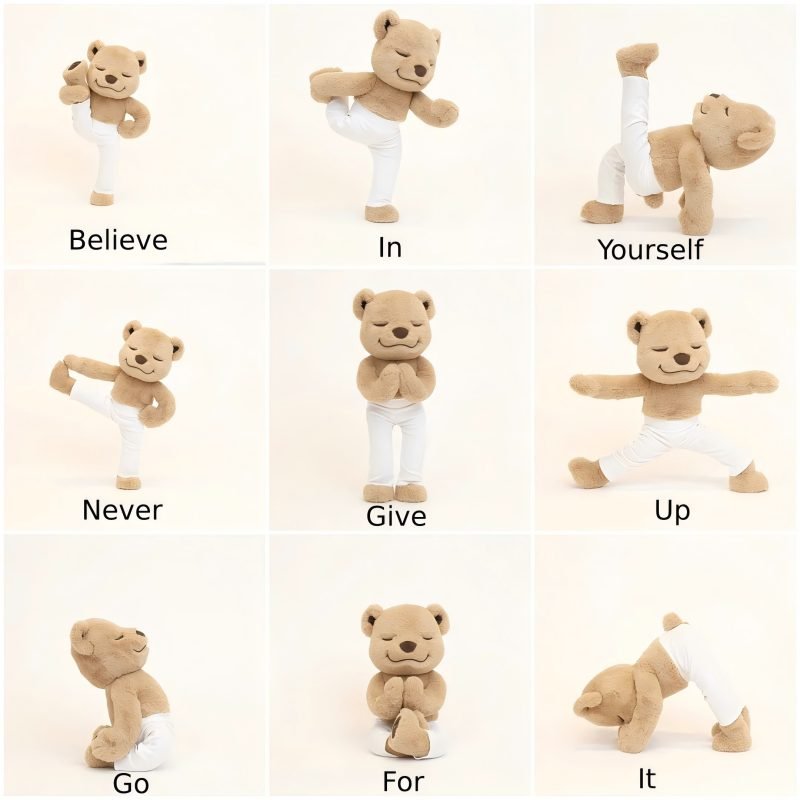

Standing or sitting stability goals

Center-of-gravity considerations

Internal support or shaping needs

Pose behavior after repeated handling

Attachment type and load stress

Reinforcement at connection points

Accessory placement stability

Safety and durability considerations

Key measurement points

Structure “must-not-change” areas

Repeatable assembly logic

Controls that prevent production drift

These checks determine whether a plush design can be built, stay stable, and be reproduced consistently—before sampling and long before mass production begins.

Breaking down the 6 structural challenges

Design Feasibility

Design feasibility determines whether a plush concept can move forward without costly rebuilds. This evaluation looks beyond appearance to assess structure, proportions, stability, attachments, and repeatability—so risks are identified and trade-offs decided before sampling rounds begin.

What pattern feasibility evaluation focuses on

Common issues this evaluation helps prevent

What buyers receive

Shape & Proportion Control

Proportion control keeps a plush character from drifting “off-model.” This step defines key ratios, reference points, and symmetry rules so facial expression, silhouette, and overall character feel remain consistent—from first sample through mass production and across different sizes.

What shape and proportion control focuses on

Common issues this control helps prevent

What buyers receive

Engineering Complex Shapes

Plush stability is engineered, not guessed. Pose and stability planning defines how weight, panels, seams, and stuffing zones work together—so a plush can stand, sit, or hold a fixed pose consistently, without collapsing, leaning, or deforming after handling.

What stability and pose engineering focuses on

Common issues this control helps prevent

What buyers receive

Attachment Engineering

Attachments create stress points that affect durability and safety. Attachment engineering evaluates load direction, reinforcement needs, and integration into the pattern—so loops, straps, and accessories remain secure during use, inspection, and shipping.

What attachment engineering focuses on

Common issues this control helps prevent

What buyers receive

Approval Outputs

Clear approvals prevent production guesswork. Pattern outputs translate design decisions into measurable standards—dimensions, placement rules, and build notes—so an approved sample becomes a repeatable reference for bulk production, not a one-off result.

What approval and repeatability control focuses on

Common issues this control helps prevent

What buyers receive

From Pattern Engineering to Sampling

Strong pattern engineering shortens the sampling process. When structure, proportions, and attachments are defined early, sample rounds focus on finish and brand clarity—not rebuilding shapes—leading to faster approvals and fewer late-stage surprises before production.

What early pattern engineering helps avoid

How this connects to sampling and QC

This connection is what allows sampling speed without sacrificing repeatability.

Consistent Bulk Output, No Sample Drift

Approved samples stay consistent in mass production only when structure decisions are engineered, documented, and measurable. Pattern engineering turns sample approval into repeatable standards—so bulk production follows defined structure logic, not visual guesswork or individual operator judgment.

What pattern engineering locks before production begins

These elements form the structural baseline every production step relies on.

How this prevents sample-to-bulk drift

This reduces variation caused by manual interpretation or production shortcuts.

6 Key Differences in a Procurement-Grade System

A “perfect sample” VS A “perfect bulk system”

What typical suppliers run into:

A “perfect sample” exists, but bulk units change—face placement shifts, seams vary, fabric feel drifts, packaging changes quietly.

What Uniomy controls instead:

Version locking after approval: the approved reference becomes the bulk benchmark, not a suggestion.

Spec boundaries defined early: what can change vs must-not-change (fabric, pile direction, fill feel, embroidery placement, packaging layout).

Change control discipline: any change triggers review before it hits production—no silent substitutions.

Customer Benifits:

Bulk stays matched to the approved reference, and reorders don’t restart the project from scratch.

A “good-looking batch” vs repeatable workstation execution.

What typical suppliers run into:

Unit-to-unit variation appears even within the same batch—tightness changes, seams drift, alignment shifts, finishing looks inconsistent.

What Uniomy controls instead:

Standard station-by-station steps: repeatable sewing path and handoff points (not “whoever is available”).

Key alignment points protected: eyes/nose/limb symmetry, openings and closures, hidden stitch finishing.

Feel and weight become measurable: fill weight ranges and fill-zone logic prevent random feel variation.

Customer Benifits:

Fewer reworks, fewer surprises at receiving, and more consistent customer reviews once the SKU scales.

A “nice fabric swatch” vs stable wear-and-wash behavior.

What typical suppliers run into:

Fabrics look good in photos but fail in bulk use: shedding, pilling, dye transfer, shrinkage, or decoration incompatibility.

What Uniomy controls instead:

Material screening by use intensity: display vs frequent handling vs high-friction items (keychains).

Risk flags before sampling: shedding, colorfastness, pile direction stability, print/embroidery suitability.

Substitution logic: alternatives are chosen to preserve the same feel target and appearance.

Customer Benifits:

Fewer compliance and durability surprises, and less re-testing caused by material drift.

A “sharp mockup” vs locked placement + repeatable pack-out.

What typical suppliers run into:

Logos become unreadable, edges lift, placement drifts, packaging varies, and kitting errors appear at scale.

What Uniomy controls instead:

Use-case selection: decoration method chosen by handling intensity (kids / display / keychain friction).

Placement rules locked: size ratio, edge finishing, stabilizer choices, wash/wear outcome.

Pack-out checklists: packaging layout and kitting accuracy kept repeatable unit to unit.

Customer Benifits:

Brand presentation stays consistent, unboxing stays repeatable, and warehouse receiving gets smoother.

“Looks fine” vs pass/fail rules with stop-and-fix control.

What typical suppliers run into:

Quality checks exist, but defects repeat; production continues; issues are discovered only when cartons arrive.

What Uniomy controls instead:

AQL pass/fail rules: defect grading + sampling logic aligned before bulk.

Stop-and-hold triggers: repeated drift pauses the run before defects spread.

Re-check after fix: the first good-after-fix unit becomes the new benchmark for the remaining batch.

Customer Benifits:

Lower defect volatility, fewer last-minute firefights, and clearer accountability when receiving teams inspect.

“Trust us” vs traceable records that protect shipments.

What typical suppliers run into:

Needle/metal incidents become serious risks, or post-delivery disputes have no traceable evidence trail.

What Uniomy controls instead:

Needle tracking + detection coverage: controlled workflow, not luck.

Batch traceability fields: production lots mapped to shipments and labeling fields.

Compliance support paths: document pack structure, testing workflow, labeling/traceability checklist.

Customer Benifits:

Lower risk exposure and faster resolution if issues arise after shipment.

Q1: Do we need perfect technical drawings to start?

No. Artwork plus a clear size target and a few references is enough to begin feasibility review and propose a sampling plan.

Q2: Can you make a plush stand on its own?

Often yes, depending on size, proportions, and design constraints. We’ll propose structure options and tradeoffs early.

Q3: Why do some designs need simplification?

Ultra-small details may not translate well to plush fabrics or may reduce durability/readability. Simplification can improve both consistency and photo impact.

Q4: How do you keep the design consistent in mass production?

We define key measurement points, placement rules, and build notes tied to the approved reference sample, then verify through staged QC.

Q5: Can you help with multi-size versions of the same character?

Yes. Multi-size consistency is planned through key ratio rules and measurement points so the character doesn’t drift across sizes.

Prevent Rework, Keep Bulk Aligned

Share artwork, target size, and intended use. The response focuses on structural feasibility, pattern trade-offs, and how designs can be prepared for stable sampling and repeatable production.

I am Nika, our team would be happy to meet you and help to build your brand plush.