Packaging & Unboxing Assembly, Executed and Verified

Packaging is where bulk orders drift: missing inserts, wrong labels, inconsistent sets, and carton errors. This page shows how packaging, kitting, labeling, and carton packing are executed as a repeatable system—so every unit matches the approved pack-out spec and arrives ready for retail, e-commerce, or 3PL intake.

Packaging, Kitting, Labeling, Carton-Out

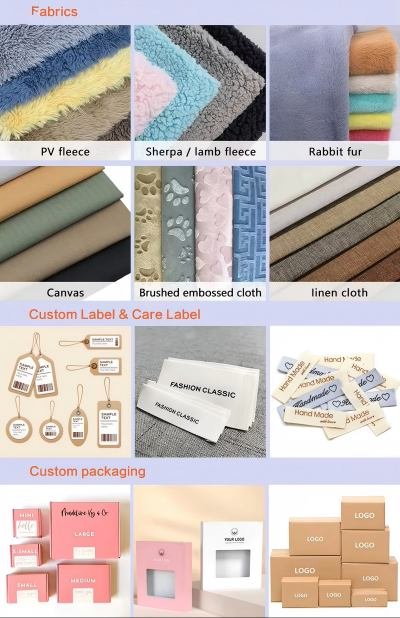

Polybag/inner bag, protective wrap, box packing, insert placement (project-dependent).

Hangtag tying, string/fastener setup, tag orientation and position consistency.

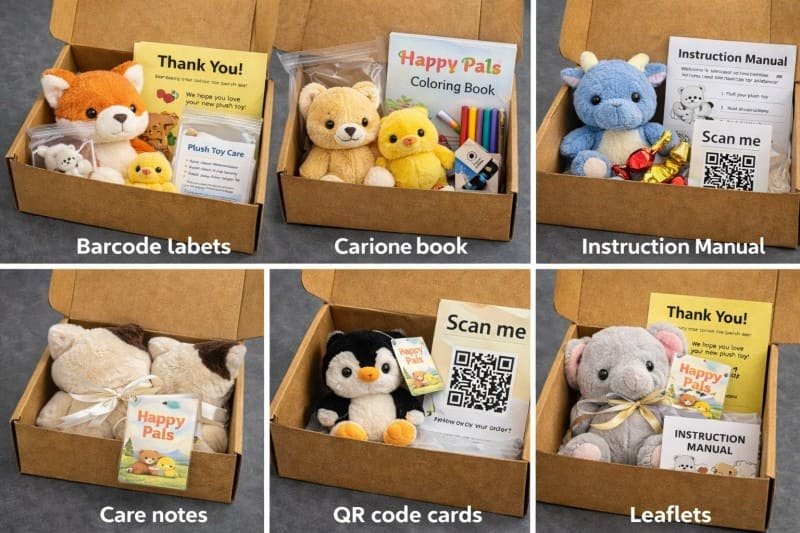

Barcode labels, warning labels, SKU labels, placement rules based on approved templates.

Instruction cards, thank-you cards, care notes, QR cards, leaflets—placed in fixed positions.

Bundling main plush + accessories + gifts + cards into repeatable sets with a pack-out BOM.

Carton quantity rules, carton marks, packing list alignment, and shipment-ready consistency.

Beyond manufacturing—pack-out execution that ships brand-ready, batch after batch.

Different Packaging for Retail, E-commerce, 3PL/FBA, Events

Different channels don’t judge packaging the same way. Pack-out needs to match the way items are scanned, handled, displayed, returned, or checked-in—so orders don’t get delayed by labeling errors, missing components, or inconsistent sets.

No missing parts. No label mistakes.

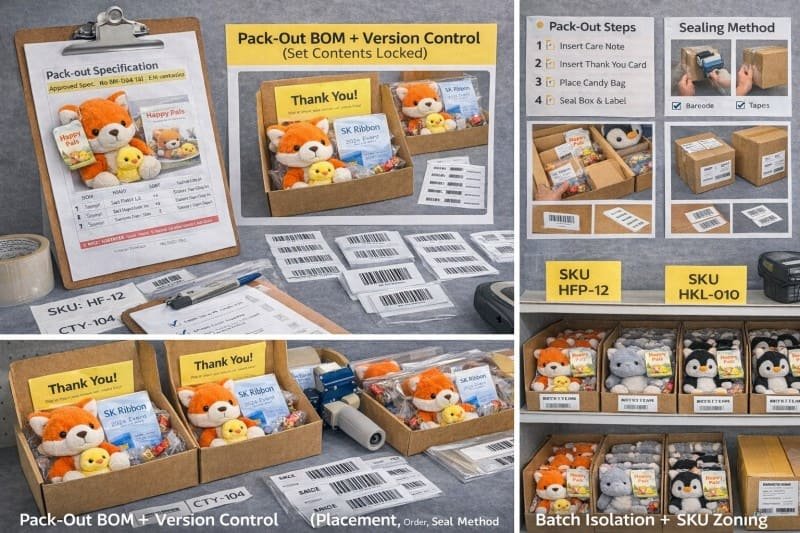

Pack-out errors don’t happen because packaging is “hard.” They happen when execution relies on memory, ad-hoc decisions, or unclear references. Consistency comes from a simple control system: one approved spec → one visible reference → one repeatable check method.

The Pack-Out Control System (Anti-Miss / Anti-Mix / Anti-Wrong-Label)

1) Pack-Out BOM + Version Control (Set Contents Locked)

2) Workstation Reference Photos (Placement, Order, Seal Method)

3) Batch Isolation + SKU Zoning (Stop Mix-Ups Before They Start)

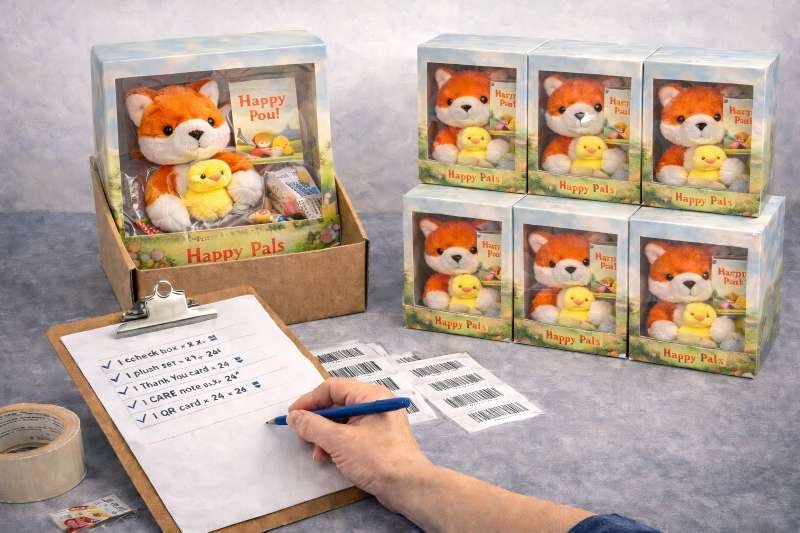

4) Two-Step Verification (No Jargon, Just Reliable Checks)

5) “One-Look” Visual Standards (Fast Pass/Fail Consistency)

A pack-out should be verifiable in seconds. The visual standard is built around:

Unboxing stays identical—unit after unit.

Unboxing is a brand moment—and it only works when presentation is repeatable. This section proves the approved unboxing layout is treated as an execution standard, not a “nice-to-have,” so every unit opens the same way across the run.

Fixed placement for every insert and add-on

Box alignment and presentation consistency (gift box / window box / inner tray)

Packing actions that protect presentation (execution only)

“Same-series” consistency across sizes and SKUs

Warehouse ready to ship Labels, Carton Marks, Packing List

Warehouse intake rejects and delays usually come from simple gaps: wrong carton marks, inconsistent carton quantities, unclear packing lists, or SKUs that can’t be verified quickly. Carton-out readiness means every carton is packed and labeled to be countable, scannable, and easy to audit—before leaving the factory.

Carton marks executed by the provided template

Consistent carton rules (count stays predictable)

Packing list that matches cartons (easy verification)

“Countable and scannable” handling—without talking shipping

Q1: Can label placement and carton marking follow a provided template?

Yes. Pack-out runs on a packing spec sheet with fixed placement rules, verified by spot checks and (if requested) photo confirmation.

Q2: Can sets, bundles, and subscription kits be assembled consistently?

Yes. Kitting runs on a pack-out BOM + count verification, with SKU zoning to reduce mix-ups and missing parts.

Q3: When should packaging be finalized—early or later?

It depends. If box dimensions or inserts constrain product size, align early. If not, packaging can be locked closer to final pre-production approval.

Q4: How are missing parts, wrong labels, and mixed SKUs prevented?

Pack-out is controlled by BOM versioning, workstation reference photos, SKU separation, and a second-person verification step on critical points.

Q5: Can pack-out photos or verification snapshots be provided without exposing brand IP?

Yes. Cropped or redacted photo sets can verify layout, labeling, and carton-out readiness while keeping sensitive artwork hidden.

Q6: Can different pack-out versions be prepared for different channels (DTC vs 3PL/FBA)?

Yes. Channel-specific pack-out rules can be set as separate versions (labels, inserts, carton rules), so each channel receives the correct configuration.

No mix-ups. No missing parts.

Send pack-out requirements, channel needs, and any label/carton templates to get a clear execution setup—Pack-Out BOM, placement references, version control, and verification points. The result is warehouse-ready cartons and repeatable unboxing, with IP-safe proof options when needed.

I am Nika, our team would be happy to meet you and help to build your brand plush.