Keychains · Pillows · Mascots · Pet Plush · Interactive · Holiday · Sustainable materials · OEM/ODM for global brands

A strong plush program is built with the same discipline as packaging: defined materials, controlled approvals, measurable checkpoints, and pack-out rules that match your channel.

A plush program that truly works must deliver:

Where brands typically use these plush builds:

Last updated:Feb. 8, 2026 · Applies to: OEM/ODM plush programs · Channels: 3PL / Retail DC / DTC / FBA-like · Covers: prototype → approvals → bulk consistency → pack-out readiness

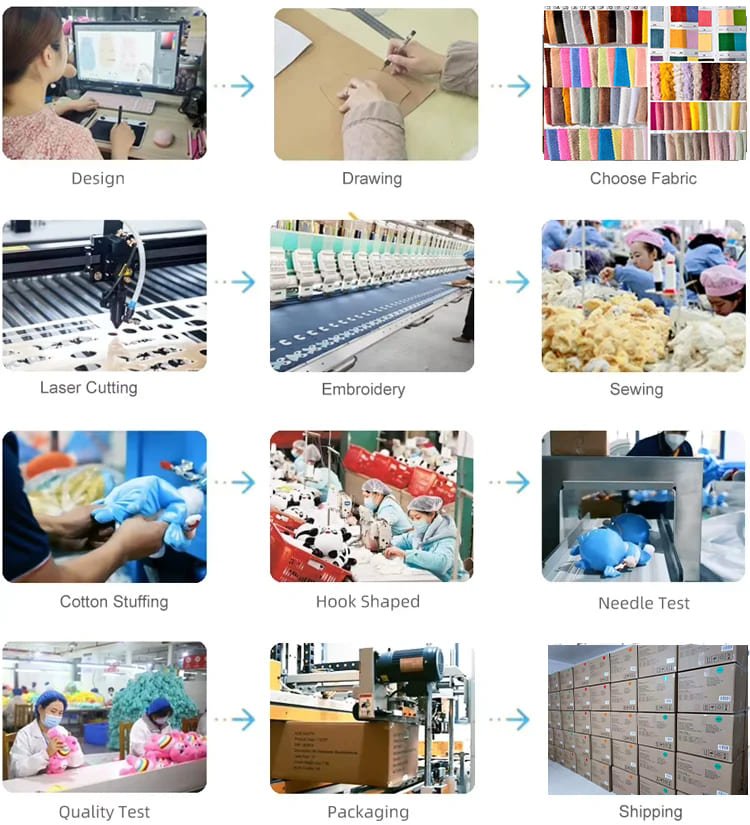

From Concept to Production: The Work Most Suppliers Don’t Show

Most vendors can “sew a plush.” A professional plush manufacturer runs a development system so your team can approve confidently—and bulk stays aligned to what you signed off.

When a brand approves a plush partner, the decision rarely hinges on “can you make it.” It hinges on whether the partner can keep the plush consistent, scalable, and channel-ready without resets.

Different retail tiers tolerate different finishes. What matters is choosing a grade your brand can repeat—then locking it.

Entry-level / promo friendly

Mid-tier retail

Premium / collectable

Plush is judged by touch and silhouette. A “nice sample” is not enough if bulk softens, slumps, or varies across cartons and reorders—so the feel + form must be engineered, not improvised.

Soft / cuddle-first

Balanced retail (touch + structure)

Structured / display-stable (character silhouette)

Brands don’t want 1,000 slightly different faces. Identity repeatability means every key visual point lands in the same place, at the same scale, with the same expression—run after run.

Simple face / promo mascot

Retail character line (multiple SKUs/variants)

Licensed / collectable IP

A plush often becomes a content object. It needs to look “clean” under close-up shots, keep brand cues visible in natural handling, and present well in unboxing—without adding fragile complexity.

Basic merch / event-ready

E-commerce retail (photo + UGC friendly)

Premium gifting / influencer moments

Most plush value is created on the second and third run. Reorder consistency means controlled materials, stored benchmarks, and explicit change handling—so later batches don’t quietly drift.

One-off / short campaign

Seasonal repeat / recurring drops

Long-running program / brand line

A Controlled plush developement System From Sample to Scale

Classic stuffed animals built for repeatable bulk consistency and durable everyday handling.

Best for toy brands, e-commerce SKUs, and gift programs needing stable reorders.

Tags: Bulk consistency · Durable seams · Stable finishing

Character and doll plush with controlled proportions, facial placement, and stable finishing from sample to scale.

Best for IP teams, creative studios, and brands managing approval-heavy character builds.

Tags: Shape accuracy · Face placement · Version locking

Brand mascots and campaign plush designed for logo clarity, shelf impact, and reorder stability.

Built for corporate merch teams, promotional programs, and campaign agencies with deadlines.

Tags: Logo readability · Placement repeatability · Deadline planning

Pet plush toys built for higher pulling and chewing intensity with safer construction choices (project-dependent).

Built for pet brands and subscription programs needing durability and repeatable safety choices.

Tags: Pull resistance · Safer build rules · Durable seams

High-friction plush keychains built for reinforced attachments, durable decoration, and consistent placement.

Best for e-commerce and campaign giveaways where daily rubbing and pulling are expected.

Tags: Reinforced hardware · Wear durability · Placement stability

Plush pillows and cushions controlled for size, rebound feel, weight consistency, and clean edges.

Best for lifestyle brands and gifting programs that need comfort-driven repeatable bulk output.

Tags: Rebound feel · Weight range · Edge finishing

Interactive plush builds with stable electronics integration, safety-first assembly, and repeatable function checks.

Built for brands and promo programs needing sound/interaction features that remain reliable in bulk.

Tags: Function testing · Safety assembly · Stable integration

Wearable plush accessories designed for fit logic, comfort, durability, and repeatable sizing.

Best for brand merch and event programs needing wearable impact with consistent fit.

Tags: Fit sizing · Comfort lining · Reinforced stress points

Seasonal plush for launches and campaigns—optimized for deadlines, repeatable appearance, and packaging readiness.

Best for seasonal campaigns, retail programs, and promotional drops with fixed ship dates.

Tags: Deadline-driven · Repeatable look · Pack-out readiness

Blind box plush series managed for lineup consistency, variant control, and collectible-ready packaging.

Best for lifestyle brands and IP programs running multi-variant drops and reorders.

Tags: Variant control · Series consistency · Kitting accuracy

Yarn-based plush styles planned for stitch consistency, clean shaping, and repeatable finishing in production.

Best for designers and boutique brands that need handmade-look builds at scalable quality.

Tags: Stitch consistency · Shape control · Finishing stability

Realistic animal plush with controlled shape, fur direction, and detail readability that holds at scale.

Best for brands and attractions needing premium realism with stable bulk repeatability.

Tags: Fur direction · Detail clarity · Shape stability

Puppet plush with controlled openings, internal structure, and consistent movement-friendly construction.

Built for kids, education, and storytelling programs that require safe, durable interaction.

Tags: Opening control · Internal structure · Reinforced seams

Mini plush and hanging ornaments optimized for small-part stability, neat finishing, and packaging/kitting accuracy.

Best for blind boxes, gift sets, and seasonal drops needing clean, repeatable small builds.

Tags: Small-part control · Neat finishing · Kitting accuracy

Baby-safe plush builds with stricter material choices, construction rules, and risk-reduction priorities.

Built for baby brands and education programs that require safer builds and clear acceptance rules.

Tags: Safer materials · No-small-parts logic · Compliance readiness

Oversized plush with shape-holding structure, controlled stuffing zones, and packable bulk execution.

Built for events, mascots, and display programs that need scale without deformation.

Tags: Support zones · Weight control · Packability planning

4 proven plush decoration methods—choose fast, scale consistently.

Best when:logos, line art, facial outlines, small-to-medium color counts, designs that must stay readable on textured plush.

Pros (what you gain)

Cons (trade-offs to know upfront)

Best when:bold color blocks, large shapes, badges/patch looks, designs that need strong contrast and clean borders.

Pros

Cons

Best when:full-color faces, gradients, complex patterns, large artwork areas that should remain soft.

Pros

Cons

Best when:you need both brand readability and rich color, or you want a premium “layered” look without sacrificing softness.

Pros

Cons

Beyond embroidery supply—an innovation system for consistent decoration.

Fabric is not a decoration choice—it determines how the plush photographs, how consistent bulk looks, and how your customers perceive quality on first touch.

Customization only works when the right details are locked early.

These are the decisions that separate smooth development from repeated resets.

8 engineered steps lock decisions and keep brands unique and outstanding.

You share brand tier, target use, channels, and launch date.

You receive: a recommended build direction + early decisions that prevent rework later.

We translate artwork into a feasible build approach: proportions, surface finish, and attachment strategy.

You receive: a draft spec direction + risk flags list.

Panels, seams, and structure are engineered so shape can be repeated in bulk.

You receive: a controlled plan showing what is allowed to shift and what must stay exact.

Fabric and key trims are confirmed with hand-feel and camera behavior in mind.

You receive: material direction + finishing expectations.

The first prototype validates proportions, identity, and key functional points.

You receive: a review checklist that separates “must-fix” from “nice-to-have.”

Changes are tracked so teams don’t approve different versions unknowingly.

You receive: updated references + a clear list of frozen elements moving forward.

A bulk-like reference is confirmed before full production.

You receive: measurable checkpoints that protect bulk consistency.

Unit packing, labels, cartons, and mapping are aligned to your receiving channel.

You receive: pack-out rules and a shipment-ready dataset.

Brands don’t reorder because the first sample was pretty. They reorder because the second and third runs still look and feel the same.

What gets protected (and how):

What your team can file internally as proof:

Plush programs show up across many launch patterns and channels:

Common receiving setups include: 3PL warehouses, retail DCs, DTC fulfillment, and FBA-like check-in environments.

1) What do you need first to start correctly?

A clear reference set, target size(s), quantity options, decoration intent, destination + receiving type, and your in-hand date.

2) Why do plush quotes change after sampling?

Usually because the true drivers changed: size, material grade, surface coverage, accessories, pack-out requirements, or compliance scope.

3) How do you prevent “one perfect sample, inconsistent bulk”?

By freezing a benchmark and using repeatable checkpoints for the visual and feel-critical points.

4) Can you support different channels like 3PL, retail DC, DTC, or FBA-like receiving?

Yes—pack-out and labeling are aligned to the rules that determine whether receiving is smooth or held.

5) Do you handle deep animal styling control here?

Animal shape/fur/feature consistency is handled on /products/custom-stuffed-animals/.

6) What if our plush includes magnets, sound, motion, or batteries?

Declare these at the start. They can change compliance scope and shipping constraints.

7) How do you support reorders?

By keeping usable references and checkpoints so later runs don’t drift from the approved benchmark.

8) Can we build multiple formats under one character program (e.g., plush + keychain + pillow)?

Yes. We align identity and brand finish across formats while controlling each format’s unique risk points.

Pick one path below. We’ll reply with a clear plan and the next required inputs—so your prototype, approvals, and bulk run stay consistent from the start.

Route A — Pilot Prototype (Fast Start)

Result: A controlled first prototype plan that reduces revision loops and locks the right priorities early.

Route B — Retail Launch (Ready-to-Scale)

Result: A tier-ready quote package plus approval checkpoints—built for repeatable bulk consistency.

Route C — Reorder & Expansion (Keep It Consistent)

Result: A version lock approach that helps your next run match the approved benchmark across repeats.

To send the correct plan, confirm these three items:

We reply with the recommended path and input checklist within 1 business day after receiving the 3 points above.

This form is built for accurate quoting—size, quantity, materials, accessories, and compliance needs. The more complete your brief, the fewer revisions and the faster your sample can start.

I am Nika, our team would be happy to meet you and help to build your brand plush.