Squeaker plush · crinkle plush · rope hybrid tug plush · plush with internal ball · multi-pack pet toys · pet retail & subscription programs

Pet plush is a stress product. It gets bitten, tugged, dragged, washed, and thrown—then judged by pet parents on how long it lasts and how safe it feels. A strong pet plush program isn’t built around “cute.” It’s built around controlled stress points, protected inserts, washable materials, and packaging/labeling that fits pet retail and e-commerce.

A pet plush that truly works must deliver:

– Reinforced seams and attachment points that resist tearing under tugging

– Insert security (squeakers/crinkle/rope/ball) designed to stay contained

– Fabric choices that balance softness with abrasion resistance

– Wash behavior that stays acceptable after real cleaning (shape, feel, stitching)

– Feature decisions that avoid unnecessary small-part risk

– Packaging and labeling aligned to pet channels and customer expectations

Last updated:Feb. 28, 2026 · Applies to: Custom pet plush OEM/ODM programs · Channels: Pet retail / 3PL / Retail DC / DTC / FBA-like · Covers: play scenario + durability spec → prototype & insert containment → approvals → bulk consistency → pack-out readiness

From Concept to Production: The Work Most Suppliers Don’t Show

Most vendors can “sew a plush.” A professional plush manufacturer runs a development system so your team can approve confidently—and bulk stays aligned to what you signed off.

The 6 Failure Points Brands Experience—and We Engineer Out

What goes wrong: seams open at the first high-load junction (ears/limbs/rope ends/handle zones)

Why it happens: load path is undefined; reinforcement is added “after the fact”

How we control it (brand-grade):

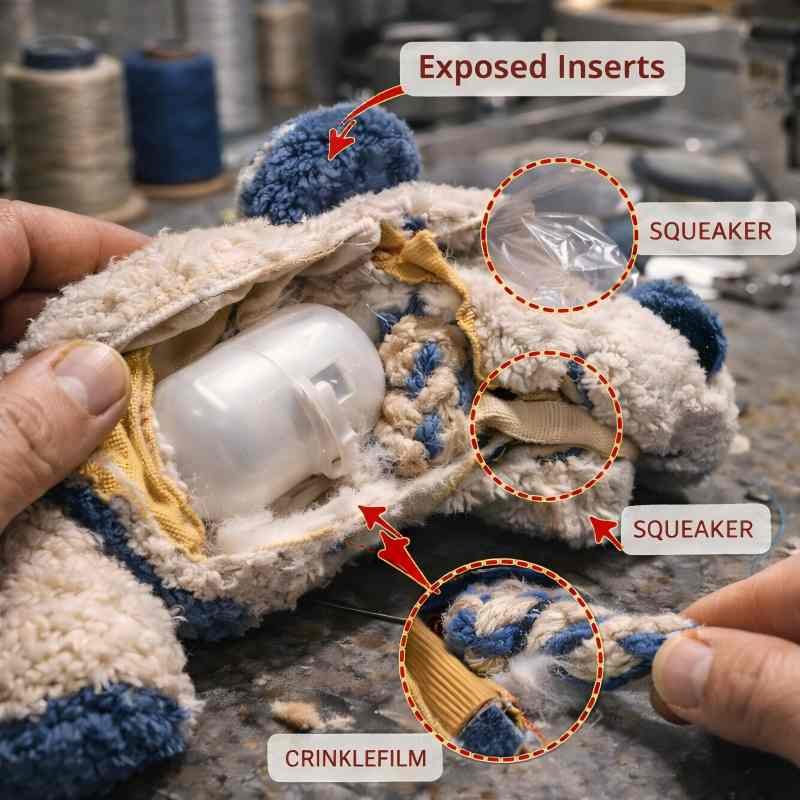

What goes wrong: inserts shift, break through lining, or become reachable

Why it happens: inserts are treated as accessories, not a containment system

How we control it (brand-grade):

What goes wrong: surface looks tired quickly; reviews mention “worn in days”

Why it happens: fabric selected by softness only; finishing varies run-to-run

How we control it (brand-grade):

What goes wrong: fill leaks from corners/edges; seams unravel under repeat biting

Why it happens: edge zones aren’t engineered; closure and junctions are weak

How we control it (brand-grade):

What goes wrong: after cleaning, shape collapses, feel changes, stitching looks messy

Why it happens: wash expectation is vague; construction isn’t designed for cleaning

How we control it (brand-grade):

What goes wrong: peg display doesn’t face correctly; barcodes don’t scan; multi-pack mis-packs; receiving rejects

Why it happens: packaging is designed after the toy; channel rules are discovered late

How we control it (brand-grade):

A Controlled plush developement System From Sample to Scale

What Makes Pet Plush Feel “Premium”? Pet plush is bought for play feedback—not just looks. We treat squeakers, crinkle layers, ropes, and internal balls as a controlled system: sound target, placement logic, containment method, and repeatable bulk execution.

Customization only works when the right details are locked early.

8 engineered steps of Pet Plush Path That Prevents Returns

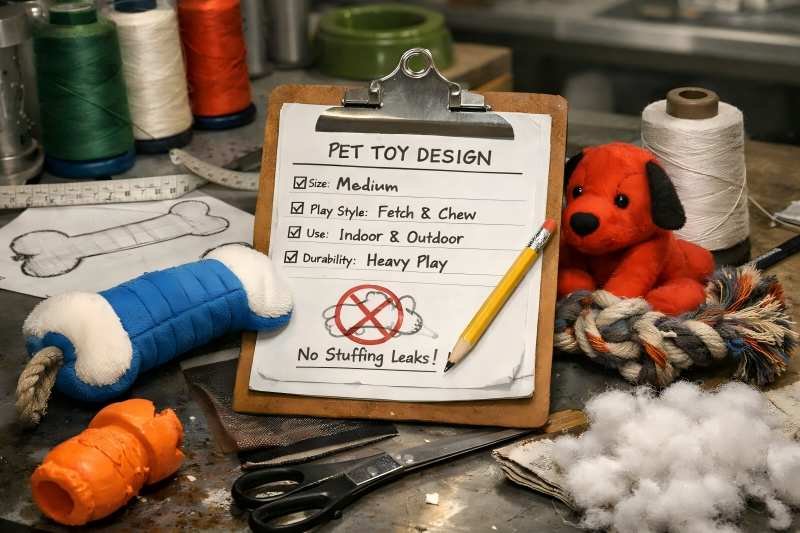

You share: pet size range, play style, and “gentle vs heavy play” expectation.

You receive: a build recommendation focused on stress points and insert containment.

We define tug zones, bite zones, and where reinforcement is required.

You receive: a reinforcement plan that guides sampling and bulk.

Fabric direction is chosen for abrasion and cleaning reality, not only softness.

You receive: fabric direction and finishing expectations.

Prototype is reviewed for seam strength, insert containment, and play feel.

You receive: a focused checklist for pet plush performance.

We adjust reinforcement, insert placement, and materials before locking.

You receive: updated reference and what is now frozen for bulk.

A bulk-like reference confirms repeatability of seams, inserts, and finishing.

You receive: measurable checkpoints that protect consistency.

Packaging and label placement are confirmed for your selling channel.

You receive: a pack-out checklist aligned to your distribution.

Stress zones are checked consistently, not only at final inspection.

You receive: consistency evidence that supports repeat runs.

Pet plush wins when customer reviews say “it lasted” and “my pet loves it.”

What gets protected:

What your team can keep as proof:

Pet Plush programs show up across many launch patterns and channels:

Common receiving setups include: 3PL warehouses, retail DCs, DTC fulfillment, and FBA-like check-in environments.

1) What is the #1 failure point in pet plush?

Seam failure and insert exposure. That’s why we build stress reinforcement and containment early.

2) Can you make a “tough” plush for heavy chewers?

We can reinforce and design for stronger play, but plush has practical limits. Setting the correct durability expectation at the start prevents disappointment.

3) Are squeakers and crinkle layers safe?

They can be, when contained and reinforced properly. We treat insert security as a core design task, not an afterthought.

4) Can these be washed?

Often yes, depending on materials and construction. Wash behavior expectations should be agreed early and validated during prototyping.

5) Do you recommend plastic eyes for pet plush?

For pet-use, embroidered features are usually safer and more durable under chewing.

6) Can you make multi-pack sets?

Yes. We define collation rules, count controls, and pack-out mapping to prevent mis-packs.

7) What should we send first?

Play scenario, pet size range, target size of the toy, insert preference (squeaker/crinkle/rope/ball), channel, and quantity options.

8) How do you keep reorders consistent?

By keeping a usable bulk benchmark and repeatable reinforcement/insertion checkpoints for later runs.

Different play styles need different build logic. Choose the route that matches how your customers actually use the toy—then we’ll return a quote-ready prototype plan.

Route A — Everyday Plush

Result: soft feel + clean finish + consistent bulk

Confirm: toy size · feature (none/squeak/crinkle) · selling format

Route B — Tug / Rope Hybrid

Result: reinforced pull points + cleaner rope integration

Confirm: tug zones · rope feel (soft/firm) · single vs set

Route C — Enrichment (Ball / Multi-sensory)

Result: stable containment + premium play feedback

Confirm: insert mix · firmness target · channel rules (labels/kitting)

Fast share your: references/artwork · pet size range · order range · in-hand date

You’ll get back: prototype plan · quote direction · pack-out outline

We reply with the recommended path and input checklist within 1 business day after receiving the 3 points above.

This form is built for accurate quoting—size, quantity, materials, accessories, and compliance needs. The more complete your brief, the fewer revisions and the faster your sample can start.

I am Nika, our team would be happy to meet you and help to build your brand plush.