Talking/recordable · Singing · Moving/dancing · Light/LED · Heated/microwavable · Sound modules · Motor modules · Magnets/batteries triggers

Interactive plush is a “system product.” The moment you add batteries, magnets, sound, motion, or heat, four things change at once: risk scope, testing expectations, shipping constraints, and pack-out discipline. The fastest projects are not the ones that rush sampling—they are the ones that declare triggers early, lock module specs early, and approve a benchmark that bulk can repeat.

An interactive plush that works must deliver:

Last updated: Feb. 28, 2026 · Applies to: OEM/ODM interactive plush programs (sound / motion / light / batteries / magnets) · Channels: 3PL / Retail DC / DTC / FBA-like · Covers: trigger confirmation → module integration → functional benchmark approvals → bulk repeatability → ship-ready pack-out

Interactive plush is not “plush + a feature.” Once you add sound, motion, light, batteries, or magnets, the project must be managed as one aligned system—so approvals hold, bulk repeats, and shipments clear smoothly.

Declare what’s inside upfront, or the project will reset later.

Lock for approval: No hidden triggers after prototype start—new batteries/magnets/electronics = scope reset and re-approval.

If it can’t ship cleanly, it’s not ready to launch.

Lock for approval: Shipping method and anti-activation steps must be frozen before final packaging is approved.

Electronics must disappear in hand—customers should feel plush, not hardware.

Lock for approval: No hard-edge hotspots—if comfort is compromised, placement and structure must be redesigned.

Repeatability comes from module control, not only sewing control.

Lock for approval: No module substitutions without re-approval—part number/spec changes are treated as a new version.

Visual approval is incomplete without a functional benchmark.

Lock for approval: No bulk greenlight without a signed functional benchmark and acceptance criteria.

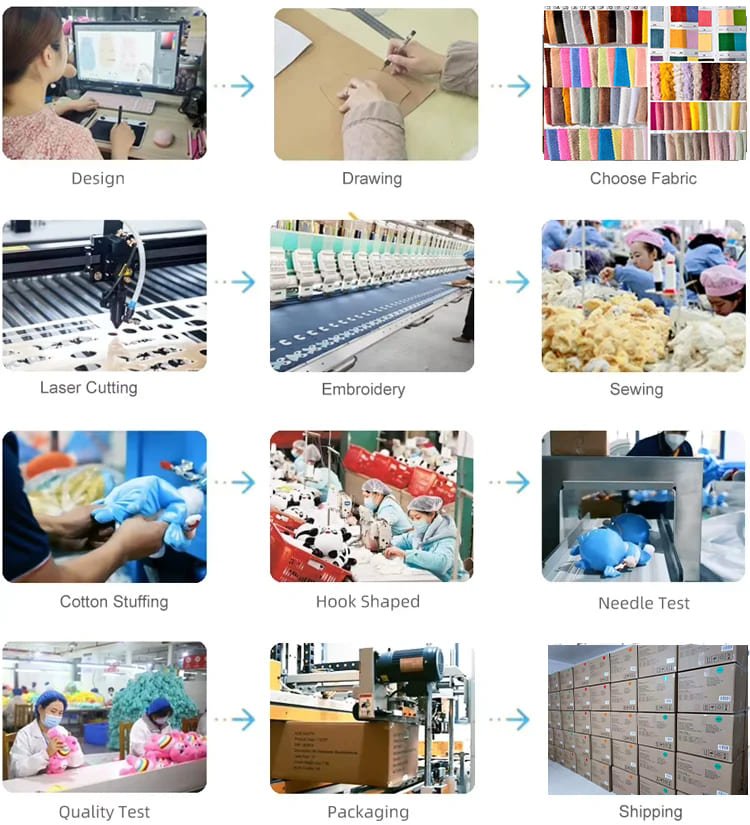

Most vendors can “sew a plush.” A professional plush manufacturer runs a development system so your team can approve confidently—and bulk stays aligned to what you signed off.

5 common interactive directions and what must be decided early for each.

Talking plush works when audio is clear, activation is controlled, and the module disappears in hand.

Lock for approval: No bulk greenlight until a functional audio benchmark is signed (clarity + volume + activation behavior).

Singing plush succeeds when sound is consistent across bulk and battery behavior is predictable.

Lock for approval: No module substitutions without re-approval—part number/spec changes = new version.

Motion plush is a stability product—movement must feel intentional, not shaky, noisy, or fragile.

Lock for approval: No production start until the plush passes a cycle + stability benchmark (pattern + noise tolerance + tip-over rule).

LED plush looks premium only when light is even, wiring is invisible, and activation is controlled.

Lock for approval: No approval unless the LED effect is verified on the actual fabric and stuffing (diffusion can’t be judged from drawings).

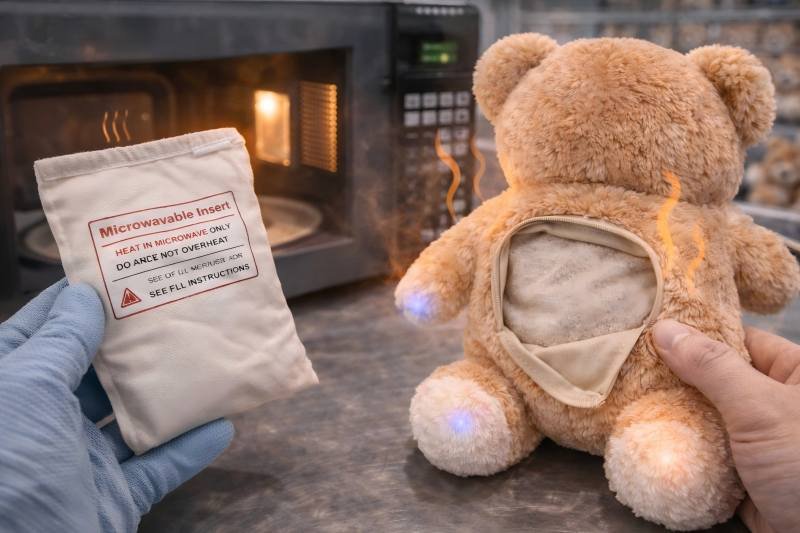

Heated plush must be engineered around safe containment and predictable user behavior—not just warmth.

Lock for approval: No launch without a defined heating-use benchmark (containment + temperature behavior + instruction set aligned to the actual build).

Interactive plush stays on schedule when “what’s inside” is confirmed on day one. When triggers surface late, teams are forced to re-approve function, re-check market expectations, revise labels/inserts, and sometimes rebuild the shipping plan.

Power (sets downstream rules)

Electronics (treat as controlled parts, not “features”)

Magnets (never “minor”)

Scope changers that commonly trigger rework

What these confirmations control

A premium interactive plush should still feel soft, balanced, and “giftable” in hand. The technology must be present—but never obvious. This section covers the integration controls that keep the plush comfortable, camera-clean, and repeatable in bulk.

Interactive plush touches multiple rule sets depending on market, age grade, and sales channel. The safest approach is to coordinate early and keep documentation consistent with the physical build.

What must be confirmed before finalizing the build

Typical compliance coordination tasks (brand + broker + testing partners)

Non-negotiable discipline:

Interactive plush needs two parallel approvals: visual approval and functional approval.

Interactive plush fails at the finish line when shipping and packing aren’t treated as part of the product system.

What pack-out must control for interactive products

No accidental activation in transit

Clear anti-activation steps (tabs/switch rules) so products don’t arrive drained or “dead.”

No crush around module zones

Packing method must protect comfort and silhouette where modules sit—no pressure marks, no deformation.

One repeatable power routine

Battery-related steps must be consistent: insulation tabs, on/off position, and any access checks.

Labels and inserts match the market and channel

Warnings, battery information, and usage guidance must match the version being shipped.

Carton mapping stays check-in friendly

Counts, variant mix rules, and carton labels must support fast receiving and low discrepancy rates.

Typical ship-ready dataset (what teams actually need)

Practical shipping rule:

If air shipping is a possibility, lock the power component decisions early. Power choices can limit options later.

Common programs that fit interactive plush well

When the project should pause and clarify before sampling

1) What’s the biggest cause of delays?

Late trigger disclosure (batteries/magnets/electronics) and unclear functional expectations. Declare triggers early and lock a functional benchmark.

2) Do we need a functional benchmark separate from the visual sample?

Yes. Visual approval does not guarantee repeatable function in bulk.

3) Can sound be clear through plush fabric?

Yes, but sound quality requires speaker placement and an opening strategy. Fabric is an audio filter.

4) Why do interactive plush projects “reset” near the end?

Usually because pack-out and labeling requirements were not frozen before the channel changed, or because module specs changed late.

5) Can one character have multiple interactive versions?

Yes, but versions must be controlled. Each variant needs clear function mapping and pack-out discipline.

6) Are magnets and batteries always a problem?

Not if declared early and controlled properly. Problems occur when they appear late without a control plan.

7) Can you ship interactive plush globally?

Often yes, but shipping options depend on the power component choices and documentation discipline. Lock those early.

For premium brands, interactive plush only scales when the module spec, approval gates, and ship-ready pack-out are fileable—so your prototype stays valid through bulk and reorders. You share:

We reply with the recommended path and input checklist within 1 business day after receiving above.

This form is built for accurate quoting—size, quantity, materials, accessories, and compliance needs. The more complete your brief, the fewer revisions and the faster your sample can start.

I am Nika, our team would be happy to meet you and help to build your brand plush.