A quick, verifiable factory snapshot—who we are, what we do, and what evidence you can review before starting a custom plush project. An overview of our factory setup, capabilities, compliance mindset, and production controls.

What you need isn’t just a “cute sample”—it’s a manufacturing partner that executes reliably at scale.

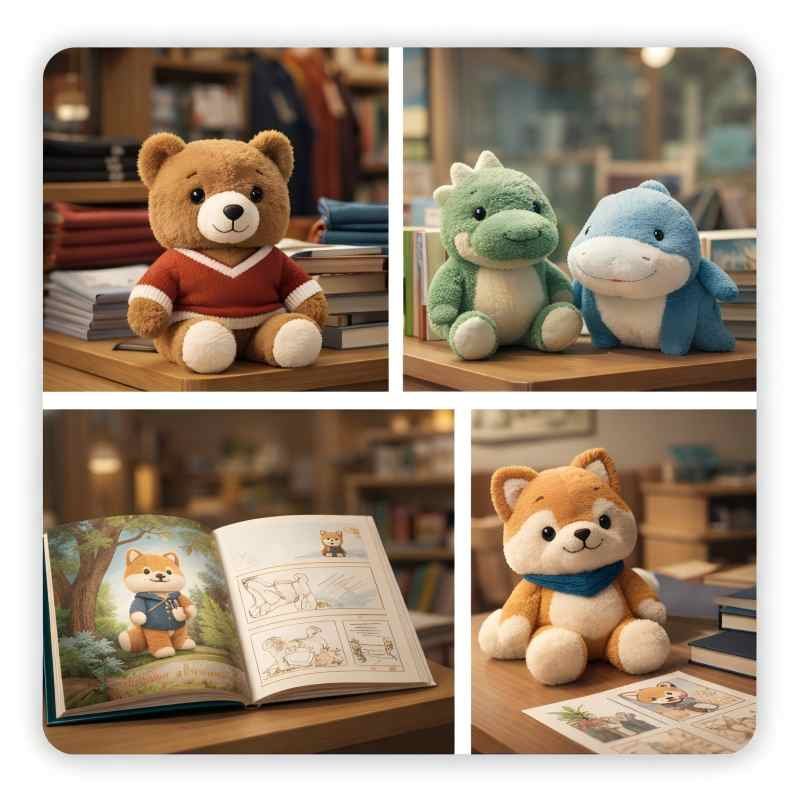

Uniomy was established to bridge the gap between a design concept and a production-ready custom plush product. Built around a coordinated workflow—pattern engineering, materials selection, sampling, decoration craftsmanship, quality control, and mass production—each project is managed under one system to reduce revisions, control risk, and keep results consistent from sample to bulk.

Located in Guangdong, China, one of the world’s most mature manufacturing hubs, Uniomy benefits from supply-chain efficiency while meeting international expectations for quality standards, compliance awareness, and clear communication.

Clients served include global brands, agencies, importers, and e-commerce teams seeking stable execution: buildable specifications, consistent workmanship, and dependable delivery.

Uniomy’s value goes beyond manufacturing capacity. Competitive plush products are built on up-to-date creativity—fresh character interpretation, trend-aware materials, smarter construction, and brand-ready details that stay consistent from sample to scale.

Many costly issues (and missed market opportunities) happen before production: the concept isn’t buildable, materials don’t perform, details don’t read well on-camera, or the final cost/timeline doesn’t match the business goal. A development-led approach is used to solve these challenges early—so the result isn’t only “cute,” but repeatable, sellable, and scalable.

A structured OEM/ODM workflow typically includes:

Trend-aligned concept translation (art → buildable plush specs that still feel “on brand”)

Character & silhouette refinement (shape language, proportions, shelf/photo impact)

Material & hand-feel direction (fabric selection, stuffing density, touch + durability balance)

Buildability & structure engineering (attachments, seam strategy, stability, safety considerations)

Prototype iteration with decision checkpoints (fewer revisions, clearer approvals)

Cost & timeline engineering (target cost, process routing, scalable workmanship)

Brand-ready finishing (logo readability, labels, packaging/kitting, delivery standards)

This approach is designed to reduce common plush risks—trend-misaligned samples, weak structure, inconsistent bulk quality, avoidable cost increases, and delays caused by late-stage redesign—while improving what matters most to buyers: a product that looks right, feels right, and ships right.

Uniomy is set up to support custom plush programs from concept to bulk delivery with a development-led workflow. Beyond sewing capacity, the system is built around spec clarity, repeatability, and brand readiness—so what gets approved in sampling can be reproduced at scale with fewer surprises.

Capability coverage typically includes:

Custom plush toys, keychains, pillows, mascots, seasonal items

Pattern engineering, prototype sampling, decoration crafts

Production routing, QC gates, packaging/kitting, shipping prep

Documentation support for brand approvals and compliance workflows

Best for: teams needing a reliable partner to turn creativity into consistent production outcomes.

Modern plush success is driven by hand-feel, durability, photo impact, and stable supply—not just a cute shape. Uniomy’s development work focuses on making designs buildable, materials performant, and outcomes repeatable.

Engineering + development support commonly covers:

Fabric selection guidance (pile, density, shedding, colorfastness)

Stuffing control (density targets, shape-hold, rebound)

Structure feasibility (attachments, seam strategy, distortion risk)

Size scaling logic across product lines (keychain → hug-size consistency)

Decoration placement planning for readability and production stability

The goal is simple: creative intent preserved, production risk reduced, scale made realistic.

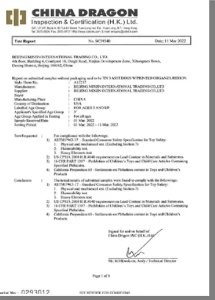

Uniomy supports a wide range of industries where character expression, brand consistency, and production repeatability are critical. Experience across multiple sectors makes it possible to adapt materials, structure, decoration techniques, safety considerations, and packaging formats to match different channels—from retail and events to licensed IP programs and institutional procurement.

Retail programs require shelf readiness, barcodes/hangtags, and stable replenishment.

Typical support: packaging/hangtag systems, carton marking for multi-store distribution, batch consistency controls, scalable workmanship standards.

Speed-to-market and predictable cost are central, but repeat-order consistency decides long-term success.

Typical support: low-MOQ pathway, structured sampling checkpoints, cost engineering, listing/photo-friendly finishing, pack-out formats for FBA or 3PL.

Food mascots are used for campaigns, membership gifts, and sellable merch—often with seasonal drops.

Typical support: character refinement for recognizability, logo/patch readability, gift-ready packaging, campaign timeline alignment, retail-ready SKUs for in-store/online.

IP programs require brand-guideline accuracy and repeatable production across SKUs and seasons.

Typical support: model-sheet/spec translation, color & detail control, embroidery/appliqué mapping, label/packaging coordination, consistency planning for reorders.

Pet plush is judged by stress durability and practical material/structure choices.

Typical support: reinforced seams, simplified part strategy, structure choices for bite stress, retail pack formats for pet channels.

Corporate programs need brand alignment + fast execution for events, onboarding kits, and client gifts.

Typical support: branding methods (patch/embroidery/print), gift-box kitting, inserts/cards, multi-variant coordination, delivery-ready packing and labeling.

Gift-shop plush must be story-aligned, retail-ready, and reorder-stable in high-traffic environments.

Typical support: character/story translation, durable fabric/shape-hold guidance, retail packaging/hangtags, high-volume replenishment planning.

Destination mascots require high recognition and strong “photo moment” design, often with seasonal refreshes.

Typical support: silhouette refinement, wearable/pose-friendly builds, seasonal accessory variants, multi-SKU lines, distribution-ready carton marking.

Hospitality plush tends to be premium-feel, gift-ready, and aligned with property identity or route branding.

Typical support: hand-feel material direction, premium embroidery/patch execution, room/gift-shop packaging formats, consistent quality for repeat runs.

Creator merch must match aesthetic direction and launch timing; packaging often supports unboxing content.

Typical support: style-aligned concept execution, limited-drop planning, special labels/tags, kitting (stickers/cards), scalable repeatability for reprints.

These programs prioritize character accuracy + collectible appeal, often across multiple sizes and accessories.

Typical support: detail mapping for high readability, multi-size scaling, accessory/attachment planning, collector-style packaging and set builds.

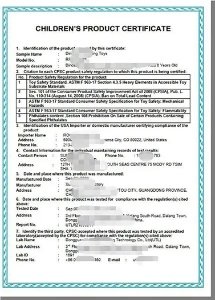

Kids-facing products often require extra attention to attachment choices, labeling, and durability.

Typical support: structure feasibility and safer attachment strategies, care/label planning, durability guidance, consistent production for series expansions.

Collabs require trend-aware creativity plus feasibility—so designs stay “special” without becoming unbuildable.

Typical support: concept-to-build translation, material hand-feel curation, decoration placement planning, seasonal variants, scalable multi-SKU execution.

Institutional buying values durability, clear identity, and simple approvals for bookstores, fundraising, alumni, and events.

Typical support: school color matching, durable construction choices, labeling options, budget-tier builds, reorder stability for ongoing programs.

Event merchandise lives and dies by deadline reliability and fan-facing photo impact.

Typical support: mascot plush development, multi-SKU sets (keychain + plush + pillow), event-date scheduling, venue/batch labeling, kitting for bundles and giveaways.

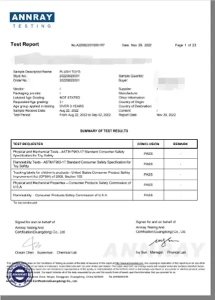

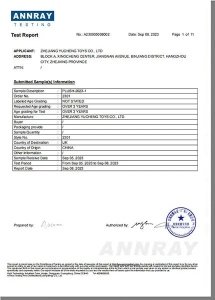

Trust is built through controls, not claims. Uniomy operates with a quality mindset designed for international buyer expectations—focusing on spec discipline, in-process checkpoints, and shipment readiness.

Quality system highlights often include:

AQL inspection options aligned to buyer requirements

QC gates across critical stages (materials → assembly → finishing → packing)

Needle/metal risk controls where applicable

Workmanship consistency checks for batch repeatability

Documentation readiness for approvals (photos, specs, packing marks, labeling references)

Certification availability can vary by project and destination market, but the operating principle remains: auditable process, consistent output.

Sustainability is treated as a practical, spec-driven decision—not a vague label. Uniomy supports brands seeking lower-impact material options and more efficient production planning while maintaining feel, durability, and commercial viability.

Sustainability support may include:

RPET / recycled materials options (fabric, stuffing) where suitable

Packaging reduction and kitting optimization

Material efficiency planning to reduce waste

Supplier documentation alignment when required by brand programs

The focus stays on what buyers actually need: credible material choices, consistent performance, and repeatable supply.

Trusted by Global Brands

Uniomy is built for long-term programs—where the goal isn’t a one-off sample, but a reliable product system that can grow. The long view prioritizes trend-aware creativity, engineering feasibility, and stable execution so product lines can expand without rework chaos.

A long-term partnership typically means:

Specs and build standards becoming clearer over time

Faster approvals through structured sampling checkpoints

Consistency improvements across repeat orders

Better cost and lead-time predictability with stable routing

The vision is straightforward: help brands scale plush lines with confidence—without losing design intent.

Q1: Are you a factory or a trading company?

We are a manufacturing factory with in-house sampling, production workflow, QC checkpoints, and packaging execution capability. You can verify through our evidence hub and factory tour materials.

Q2: Do you support OEM/ODM and private label branding?

Yes—branding elements such as embroidery, patches, labels, hangtags, and packaging can be supported based on your program.

Q3: Can we see your factory workflow?

Yes. Start with our factory tour page and capability proof pages. Visual materials and redacted documentation examples can be provided upon request.

Q4: How do you confirm capacity and lead time?

We evaluate capacity by design complexity, process bottlenecks, SKU count, and packaging requirements, then provide a milestone-based plan.

Verify Fast, Then Start With a Controlled Plan

If you need a plush factory you can trust on quality, timelines, and accountability—start here, and verify everything before you spend on sampling.

I am Nika, our team would be happy to meet you and help to build your brand plush.