Seasonal plush · Christmas · Valentine’s · Halloween · Easter · Lunar New Year · gift sets · ornaments/plush add-ons · retail & DTC

Holiday plush is schedule-driven. The “design” matters, but the winning factor is whether the product is approved, produced, packed, and delivered inside a narrow receiving window—without rework caused by late packaging rules or seasonal material shortages. A strong holiday plush program is built around back-planning, early locks, and pack-out discipline so your launch date stays non-negotiable.

Holiday plush programs work best when they deliver:

Last updated:Feb. 28, 2026 · Applies to: Custom Holiday Plush (seasonal drops & gift-set programs) · Channels: 3PL / Retail DC / DTC / FBA-like · Covers: back-planning to in-hand week → seasonal trim & variant control → sampling locks → gift-set kitting accuracy → peak-season pack-out & receiving readiness → wave-2 replenishment or close-out plan

From Concept to Production: The Work Most Suppliers Don’t Show

Most vendors can “sew a plush.” A professional plush manufacturer runs a development system so your team can approve confidently—and bulk stays aligned to what you signed off.

When a brand approves a plush partner, the decision rarely hinges on “can you make it.” It hinges on whether the partner can keep the plush consistent, scalable, and channel-ready without resets.

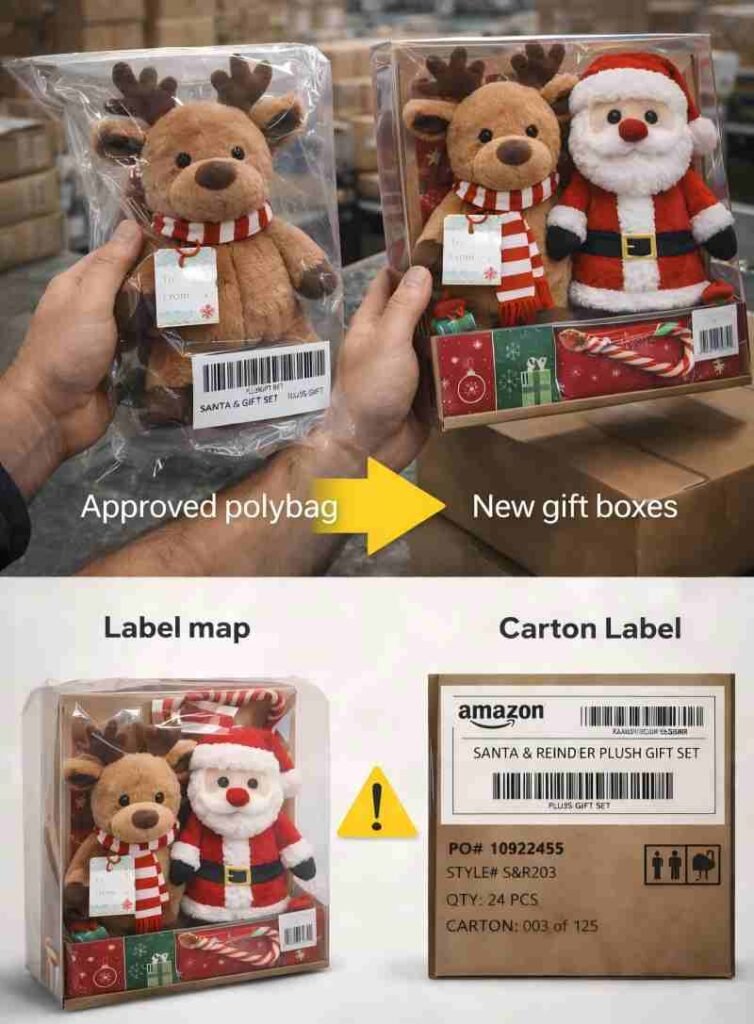

Holiday plush often gets approved visually first—then packaging arrives as a separate conversation. That split is what causes late resets: gift boxes change unit dimensions, inserts change kitting steps, and label rules change what the warehouse will accept.

Typical cause: gift box, insert cards, or labeling rules introduced after sampling approval.

What we lock to prevent this:

High-end launch discipline: packaging is treated as part of the product, not decoration. If it changes the unit footprint or receiving workflow, it is a “version change,” not a “minor edit.”

Seasonal trims create two risks that don’t exist in normal programs: availability peaks (everyone buys at the same time) and visual drift (metallics, reds, ribbons vary between batches).

Typical cause: specialty ribbons, metallic threads, or themed accessories selected too late.

Holiday-specific controls that matter:

What brands get wrong: treating trims like easy add-ons. In holiday programs, trims are often the longest pole.

Holiday misses rarely come from one big mistake—they come from approval creep: too many “tiny improvements,” late rounds, and booking started after everything is finished.

Typical cause: approvals drift, revision rounds expand, or booking is planned after everything is finished.

The control is not “work faster.” It’s a calendar that enforces boundaries.

High-end clarity: a holiday program has a point where you stop optimizing and start executing. Without that line, you don’t have a launch plan—you have an endless prototype.

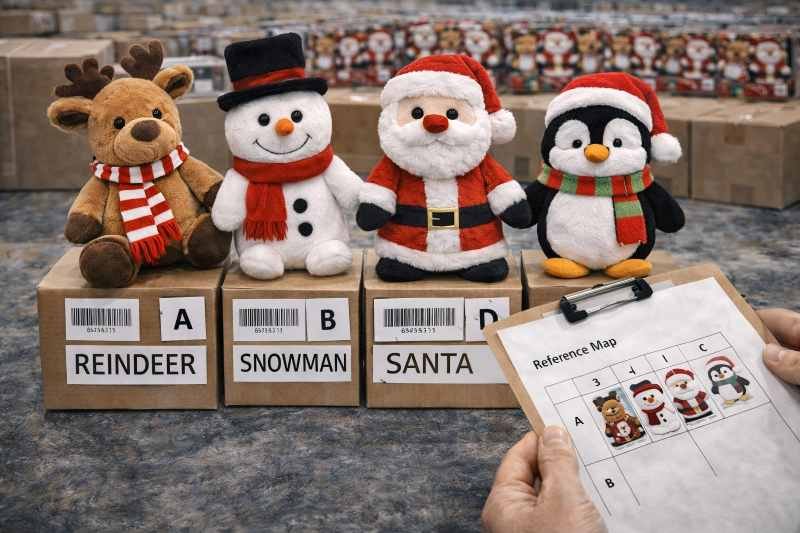

Holiday plush commonly ships as bundles: plush + accessory + card + seasonal insert. This is where operational failure shows up as customer complaints: wrong variant, missing insert, mixed cartons, inconsistent sets.

Typical cause: bundle rules not defined, variants not controlled, carton mapping unclear.

The system solution is an “Assortment Map,” not a reminder.

High-end outcome: set accuracy becomes repeatable, not dependent on “careful workers.”

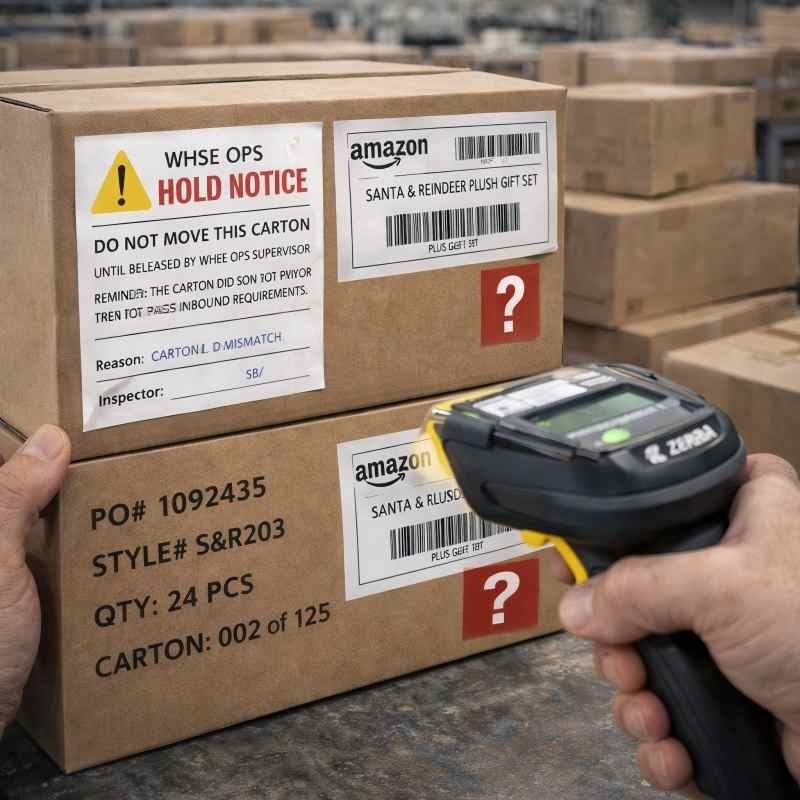

During peak season, warehouses tighten rules because volume spikes. What passes in April might get held in October/November. Holds usually happen for reasons that feel “small” but are pass/fail operationally: barcode placement, carton marks, mapping data mismatch.

Typical cause: carton marks/labels don’t match receiving SOP; mapping data inconsistent.

What we align before labels are printed:

Holiday-specific truth: receiving is part of the launch window. A truck that arrives but can’t check in is not “delivered” in holiday terms.

Holiday plush has a unique “success problem”: if it sells out, you may want Wave 2—but seasonal materials, trims, packaging, and capacity windows may no longer be available. Without a plan, “replenishment” becomes a new project with new risks.

Typical cause: no plan for replenishment materials and benchmark references.

The decision you must make early (even if you’re unsure):

What we preserve if Wave 2 is possible:

High-end framing: replenishment is not “just make more.” It’s a controlled extension of the season—only possible if you kept the path open.

6 formats you choose changes cost, speed, and pack-out complexity.

Holiday programs are won by premium-looking details that still stay available, repeatable, and pack-out friendly in peak season.

Best-fit product types (holiday plush formats):

Fabric families that tend to behave best in holiday reality (choose by program tier):

Technical difficulties (holiday-specific failure modes):

Brand-facing decisions to lock early (prevents resets):

Best-fit product types (where trims actually add value):

Trim types commonly used in holiday programs (choose with timing discipline):

Technical difficulties (why trims cause delays):

Brand-facing lock list (prevents late resets):

Best-fit product types (where graphics carry the seasonal message):

Common graphic methods used in holiday plush (each with trade-offs):

Technical difficulties (holiday-specific pain points):

Brand-facing decisions that protect premium perception:

Best-fit product types (packaging-led holiday programs):

Packaging material options commonly used (choose by channel and timeline):

Technical difficulties (why packaging causes late resets):

Brand-facing lock list (non-negotiable for holiday timelines):

This section focuses on decisions that directly impact schedule control and pack-out success.

Freeze these before you call a sample “final.” If any of them moves late, the timeline usually resets.

Holiday boundary: after pack-out freeze, any change that affects unit dimensions, labeling, or variant mix becomes a next-season change.

These can move later only if the structure and placement are already locked.

Think of this as “copy and finish,” not “structure and workflow.”

Holiday programs often sell as bundles, and mis-packs spike during seasonal volume. Treat the set as a controlled system.

Lock a single Assortment Map that ties together:

If your team can’t explain the set in one clean map, it will drift in bulk.

Wave-2 success only happens if the path is kept open before bulk begins.

Choose one strategy early:

What changes with this choice: how tightly you lock materials, how you preserve benchmarks, and whether trims/packaging must remain reorderable.

Deliverable you can file: a reorder-ready reference set (version lock list + assortment map + pack-out rules) so Wave-2 doesn’t become a new project.

6 engineered timeline logic keep brands unique and outstanding

You share: concept references, target sizes, quantity options, channels, and in-hand date.

You receive: a back-planned timeline with lock points.

Prototype validates: look, key festive details, and any kitting impact.

You receive: a focused checklist that prioritizes deadline-critical issues.

We revise only what changes sellability or causes bulk risk.

You receive: updated reference + what is now frozen.

A bulk-like reference confirms repeatability and pack-out readiness.

You receive: measurable checkpoints and a pack-out freeze.

Production runs with version stability. Pack-out follows a fixed checklist.

You receive: mapping and documentation consistency for receiving.

Booking and documents align to your channel.

You receive: carton mapping dataset and receiving-aligned packing files.

Holiday launches don’t slip because of one reason—they slip because small uncertainties compound late.

What keeps the program controllable:

What your team can keep as proof:

Plush programs show up across many launch patterns and channels:

Common receiving setups include: 3PL warehouses, retail DCs, DTC fulfillment, and FBA-like check-in environments.

1) What should we decide first for a holiday plush project?

Your in-hand date, selling channel, packaging direction, and 1–2 hero festive details. Everything else should protect those.

2) Why do holiday projects reset late?

Packaging and receiving rules were not frozen early, or seasonal trims were chosen too late.

3) Can we do gift sets and bundles?

Yes. Kitting rules must be written early and mapped to cartons to avoid mis-packs and receiving disputes.

4) How do you reduce sampling rounds for holiday timelines?

By defining what matters most for sellability and freezing non-negotiables early, then limiting revisions to deadline-critical changes.

5) What if we want multiple variants or a collection?

That’s common for holiday assortments, but variant control (labels, mapping, pack-out discipline) must be treated as part of the core plan.

6) Can we replenish if the launch sells out?

Often yes, but only if you chose a reorder-ready strategy early and kept materials and references usable.

If you’re planning a seasonal drop with a hard in-hand week—Black Friday, Christmas, Valentine’s, Halloween, Easter, a winter gifting run, or a limited-edition holiday variant—your plush program needs more than “a cute sample.” It needs launch control:

Back-planning from your in-hand week (no-reset points, booking cutoffs, approval gates)

Seasonal trims + color risk control (trim freeze list + safe substitute rules)

Holiday version locks (what must be frozen vs what can stay flexible)

Gift-set + kitting discipline (assortment map, insert rules, mis-pack prevention)

Peak-season receiving readiness (labels, carton marks, carton mapping for 3PL/DC/FBA-like)

Wave-2 decision support (top-seller restock vs clean close-out)

Share your target plan we reply with the recommended path and input checklist within 1 business day.

This form is built for accurate quoting—size, quantity, materials, accessories, and compliance needs. The more complete your brief, the fewer revisions and the faster your sample can start.

I am Nika, our team would be happy to meet you and help to build your brand plush.