Plush throw pillows · character pillows · shaped cushions · travel pillows · gift-set inserts · retail & DTC

A plush pillow is a “feel product” and a “shipping product” at the same time. Customers judge it by softness, rebound, and how it holds its silhouette on a sofa or in an unboxing video. Brands judge it by freight cost, carton efficiency, and whether the pillow arrives cleanly compressed—or arrives deformed and triggers returns.

A plush pillow that works must deliver:

Last updated:Feb. 28, 2026 · Applies to: custom plush pillow OEM/ODM· Channels: 3PL / Retail DC / DTC / FBA-like · Covers: fill-feel definition → shape & seam controls → prototype approvals → bulk consistency → compression & carton pack-out readiness

Many suppliers treat pillows as simple shells + stuffing. In real programs, the pillow must feel right, hold shape, and ship profitably.

When a brand approves a plush partner, the decision rarely hinges on “can you make it.” It hinges on whether the partner can keep the plush consistent, scalable, and channel-ready without resets.

What it looks like: some units feel cloud-soft, others feel flat or over-stuffed; squeeze test and rebound don’t match your approved sample.

Typical cause: fill weight tolerance too loose, fill isn’t stabilized (migrates in transit), shell cutting variance changes internal volume.

How we prevent it: we lock a Feel Spec instead of vague adjectives—target loft, squeeze resistance, and rebound behavior—then pair it with size-based fill weights and a fill distribution method (so the center/edges don’t drift). Bulk checks are based on feel + weight, not “looks OK.”

What it looks like: empty corners on shelf photos, or puffy corners that make the pillow look cheap and uneven.

Typical cause: panel geometry not designed for corner fullness; fill migrates away from corners; seam allowance/turning method creates corner distortion.

How we prevent it: we engineer corners as a system—corner geometry + seam strategy + fill retention—and confirm the pillow holds its shape after handling (hug, press, shake). For square/rectangles, corner fullness is treated as a measurable checkpoint, not an aesthetic hope.

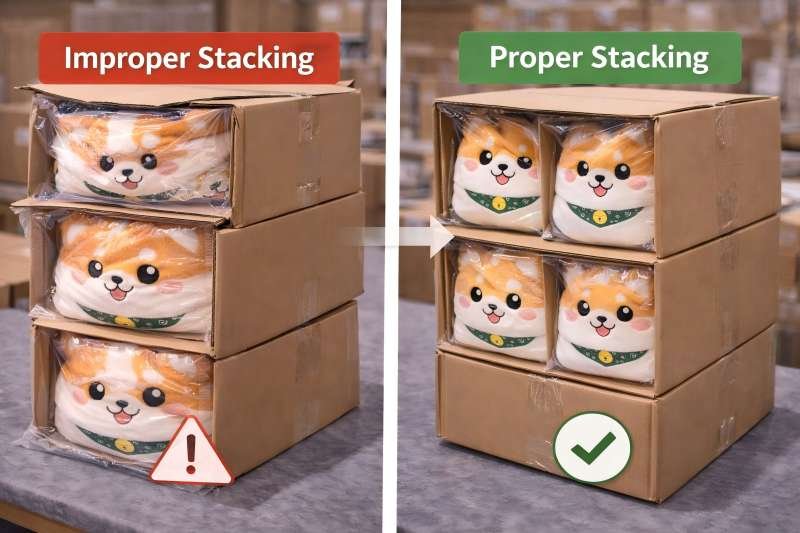

What it looks like: pillow arrives “dead,” slow to recover, or never returns to the approved loft—especially obvious in unboxing videos and customer reviews.

Typical cause: compression level chosen without considering fill type and surface fabric; recovery expectations not defined; cartons stacked in a way that crushes loft; long pile surfaces show pressure marks.

How we prevent it: we choose compression based on pillow type + fill behavior, then define a recovery expectation (how it should look after a set time out of carton). Carton stacking rules protect loft and surface finish, so you don’t trade freight savings for returns.

What it looks like: the quote looks fine, but shipping becomes the profit killer because pillows are volume-driven.

Typical cause: thickness and loft not engineered for carton efficiency; no carton plan early; pillow dimensions don’t align to practical carton footprints; compression feasibility discovered too late.

How we prevent it: we lock a carton reality early—target carton footprint, units per carton, max weight, compression allowance—then design the pillow’s loft and pack-out around it. Your program is built to ship profitably, not just to sample beautifully.

What it looks like: character faces stretch when the pillow is filled; embroidery/print sits on a flexible area and looks distorted; alignment drifts between units.

Typical cause: decoration placed across high-tension zones; surface art wasn’t planned around seam lines; large coverage on plush stretches differently by fill density.

How we prevent it: we define stable decoration zones and map placement to panels that don’t deform under fill pressure. For character pillows, we lock a photo reference standard for face alignment (front-on camera read), not just a flat artwork position.

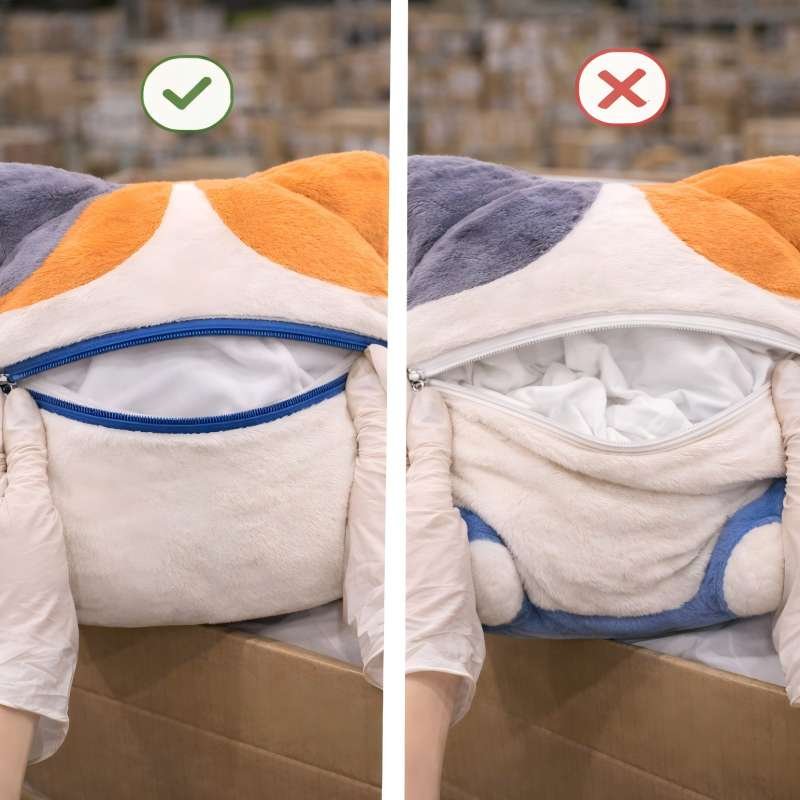

What it looks like: zipper line waves, silhouette bends, one side sits higher; insert bunches, corners wrinkle.

Typical cause: zipper placed on a tension edge; zipper tape stiffness fights the shell; insert dimensions don’t match shell volume; stitch line pulls the surface.

How we prevent it: we place closures where they won’t fight the silhouette, match insert sizing to shell volume, and lock a zipper finish standard (alignment, smoothness, no rippling). The result is a pillow that looks premium on shelf and stays premium after use.

A Controlled plush developement System From Sample to Scale

Best for: home lines, lifestyle drops, retail shelves, DTC bundles

What makes it feel premium: even loft, clean edges, full corners, “same squeeze” across cartons

Must Lock:

Best for: IP brands, creator merch, kids lines, drop culture cushions

What makes it premium: silhouette reads instantly, face stays aligned on a filled pillow, arrives uncrushed

Must lock:

Best for: playful décor, giftable drops, cozy collections

What makes it premium: true roundness, smooth seam lines, consistent “hug feel” without lumps

Must lock:

Best for: travel brands, gift bundles, seasonal promotions, convenience retail

What makes it premium: holds ergonomic curve, rebounds after use, stays hygienic in packaging

Must lock:

Best for: functional merch (remote pocket, small storage), couch accessories, gifting

What makes it premium: pocket sits flat, doesn’t distort silhouette, survives repeated use

Must lock:

Best for: novelty lines, mood products, seasonal drops, social-content items

What makes it premium: flips smoothly, aligns cleanly, looks intentional on both sides

Must lock:

Plush pillows are volume-driven. Compression can protect margin—but only if loft recovery is designed and verified. This section defines how we choose compression levels, set recovery expectations, and prevent surface crush, so pillows arrive premium in unboxing and stay premium on the couch.

6 custom plush pillow options

8 engineered steps lock decisions and keep brands unique and outstanding.

You share: size, channel, “feel words,” and your in-hand date.

You receive: a fill + pack-out direction designed around carton efficiency.

We choose a shell construction that holds shape and a fill strategy that matches your feel.

You receive: a practical build direction (what must not change later).

Fabric is chosen for surface uniformity and handling behavior.

You receive: fabric direction and finishing expectations.

Prototype review focuses on feel, rebound, corner fullness, silhouette, and surface finish.

You receive: a review checklist aligned to pillow realities.

We adjust fill weight/distribution or shell geometry before locking.

You receive: updated reference and what is now frozen.

A bulk-like reference confirms repeatable feel and shape stability.

You receive: measurable checkpoints for fill weight and silhouette.

Compression level and carton plan are confirmed based on your channel.

You receive: packing rules that protect shape and reduce freight.

Shape-critical points (corners, thickness, symmetry) are checked consistently.

You receive: consistency evidence that supports reorders.

Premium pillow programs don’t scale on “memory.” They scale on a filed reference set your team can reuse—so new teammates, new seasons, and new reorders don’t change how the pillow feels, looks, or ships.

What we build for you (so the program is governable):

6 common pillow program patterns brands run—each with different priorities.

1) What causes pillows to feel inconsistent?

Fill weight variation and distribution variation. That’s why we lock fill targets and distribution rules early.

2) Can you control corner fullness and prevent lumps?

Yes—through shell geometry choices, fill planning, and checkpoints during production.

3) Can pillows be compressed for shipping without damage?

Often yes, but compression level must match the pillow type and surface fabric, with recovery expectations defined.

4) Why is freight cost such a big deal for pillows?

Because pillows ship as volume. Carton efficiency and compression rules directly shape landed cost.

5) Can we do shaped pillows with character faces?

Yes—silhouette stability and decoration placement must be engineered so faces stay clean and aligned.

6) Do you offer removable inserts and zippers?

Yes. Zipper placement and insert sizing must support shape rather than distort it.

7) Can we match a full plush character and a pillow version?

Yes. Identity can stay consistent while the construction is redesigned for pillow stability and shipping efficiency.

Plush pillows don’t fail in sampling—they fail after compression, stacking, and real handling. Send a few inputs and we’ll run a pillow-specific risk screen, then return a build plan that locks hand-feel, silhouette, and carton economics before bulk.

Share these fast inputs:

We reply with the recommended path and input checklist within 1 business day after receiving the 3 points above.

This form is built for accurate quoting—size, quantity, materials, accessories, and compliance needs. The more complete your brief, the fewer revisions and the faster your sample can start.

I am Nika, our team would be happy to meet you and help to build your brand plush.