Needle and foreign-metal risk is managed through accountable needle control, defined detection checkpoints, and traceable reject handling. This page documents what stays in scope, what gets verified, and what evidence is produced for approvals and compliance files—focused on repeatability in bulk, not tutorials.

Reduce hidden metal risk with controls

A broken needle is not “a production incident”; it is a hidden foreign-metal risk. The core objective is simple: prevent any needle fragment (or unknown metal piece) from being sealed into a finished plush and shipped. That requires two things to be true—every time, for every lot:

Problems this control system solves for the project owner

Visible Failure Modes Before Shipping

Checks are organized around buyer-visible failures—the issues that show up in photos, unboxing, handling, and receiving. Each category follows the same logic: risk → checkpoints → recorded outputs.

Coverage is set by three realities: where metal can be introduced, where a fragment can be trapped, and where rework can re-enter packing. The objective is consistent release: no unit moves forward unless its risk path is covered, cleared, and recorded.

Reinforced coverage fits when:

Decision Factors (fast checklist)

A detection system fails in one common way: items quietly move around it—during rework, shift handoffs, changeovers, or rush packing. The control focus here is simple: every unit follows the same mandatory pass points, and anything that fails stays out until it is cleared. No operating steps or standards—only what gets locked so results stay consistent batch after batch.

Locking matters most when:

Decision Factors (fast checklist)

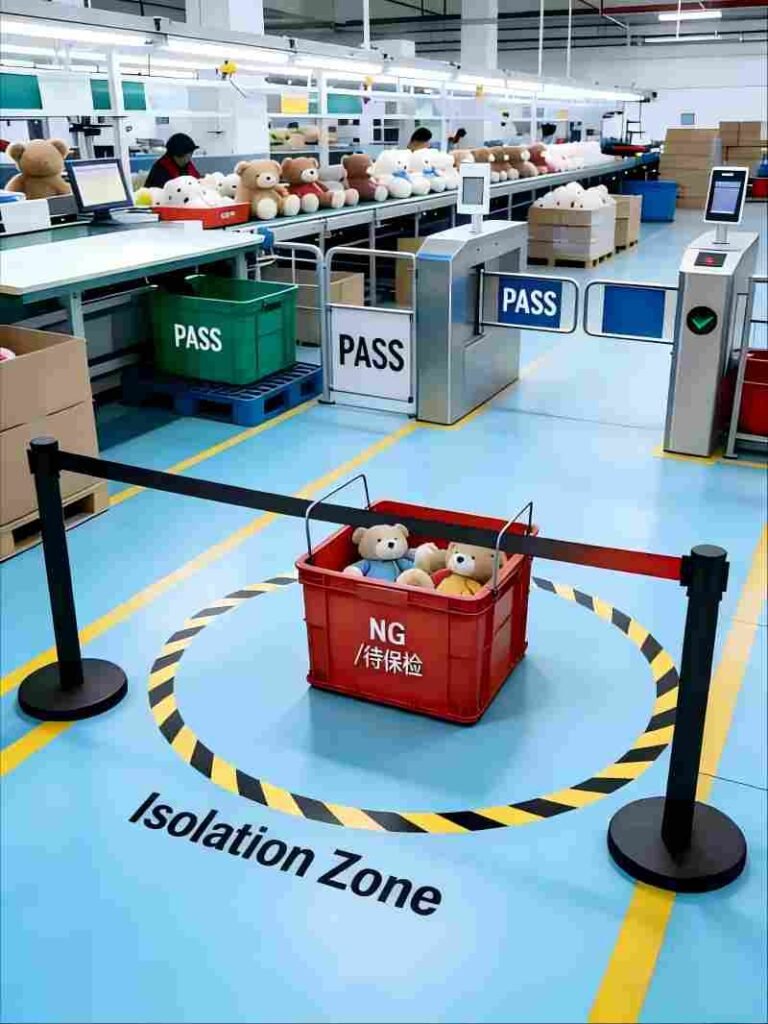

A reject is only safe when it stays out until it is cleared. The failure mode is simple: rejected or “to-be-rechecked” pieces quietly drift back into packing during rework, shift handoffs, or rush output. The control objective is a checkable closed loop: a visible isolation zone, unmissable status tags, controlled routing, recorded disposition, and batch linkage so packing only receives cleared pieces.

Locking rejects matters most when:

Decision Factors (fast checklist)

Every needle is accounted for always.

A broken needle is not treated as “an inconvenience.” It is treated as a potential foreign-metal event until proven otherwise. The purpose of needle accountability is to remove the two biggest sources of risk in bulk production: unknown needle count and unclear incident scope.

What gets guaranteed by the needle system

No “missing needle” blind spots

Issued needles and returned needles must reconcile. A missing needle is treated as an unresolved risk until the status is closed on record.

A broken-needle event triggers a controlled hold

Affected work-in-progress is placed on hold based on a bounded scope (station/time window/identified pieces), not vague “check everything.”

No return to normal flow without clearance

Pieces under hold are not allowed to re-enter normal production or packing until clearance is recorded.

Repeat orders stay consistent across shifts

Needle accountability prevents “it depends on who is working” outcomes by keeping the same incident logic across teams.

What typically improves on real orders

Clear limits avoid false confidence.

Metal detection and broken-needle control reduce a specific risk: unknown metal inside shippable goods. They do not replace other safety controls, and they do not “guarantee everything is safe” by themselves. Clear boundaries prevent the most expensive mistake in approvals: assuming one control covers all risks.

What this system does not solve

Non-metal foreign objects

Plastic fragments, thread balls, foam bits, broken zipper teeth made of non-detectable materials, paper, or other non-metal debris require separate prevention and inspection controls.

Design-driven hazards

Small-part risks, sharp edges on accessories, pinch points, and age-related safety decisions are not solved by detection. These must be controlled at design/spec level and attachment engineering.

Chemical and material compliance risks

Odor, dyes, migration concerns, restricted substances, and material declarations sit outside detection/needle control and need their own documentation and testing routes.

Performance claims unrelated to metal risk

Wash durability, seam strength, print/embroidery wear, and appearance retention require different verification methods.

Physical limits under extreme builds

Very thick assemblies, ultra high-pile surfaces, dense internal structures, or certain weighted designs can reduce detection reliability unless coverage is adapted and documented.

Where mistakes usually happen (and how to avoid them)

Q1: Do you use metal detection for every order?

Metal detection coverage is set by program risk and documentation expectations, not by a one-size rule. Coverage level and mandatory checkpoints are defined per product (materials, thickness, accessories, rework likelihood), then tied to the lot record pack for review.

Q2: What happens if a needle breaks during production?

A broken needle is treated as a foreign-metal event until closed out. The response follows a defined close-out path: stop-and-hold, bounded quarantine, fragment search/recovery, re-check, then release only with recorded clearance.

Q3: Can needle policy and records be shared?

Yes—shared materials typically include policy summaries and redacted templates (needle ledger, incident form, reject tag, checkpoint map). Project-specific logs can be provided in the format required for approvals, with sensitive internal details removed where necessary.

Q4: How is traceability maintained if an incident occurs?

Records connect time window + workstation/line references to lot identifiers, then link to detection checkpoint results and packing-batch readiness. This makes the affected window identifiable and prevents uncontrolled release during rework or handoffs.

Q5: How does this relate to AQL inspection?

AQL is a sampling evaluation of batch quality at an inspection point. Needle and metal control is a preventive + containment system that runs through production gates and focuses on no-bypass release discipline when metal-risk events occur.

Fewer defects. Clear release decisions.

Send product photos + materials + target market. Receive a checkpoint plan outline and the record-pack list used for bulk release and incident close-out.

I am Nika, our team would be happy to meet you and help to build your brand plush.