Want to verify a real factory? This is a buyer-first factory tour: scan the workflow map, view photos/videos by area, and jump to proof pages if you need standards, records, and QC evidence. It’s designed for procurement and QA teams to validate quickly.

Check the workflow map (sampling → production → QC → packing → warehouse)

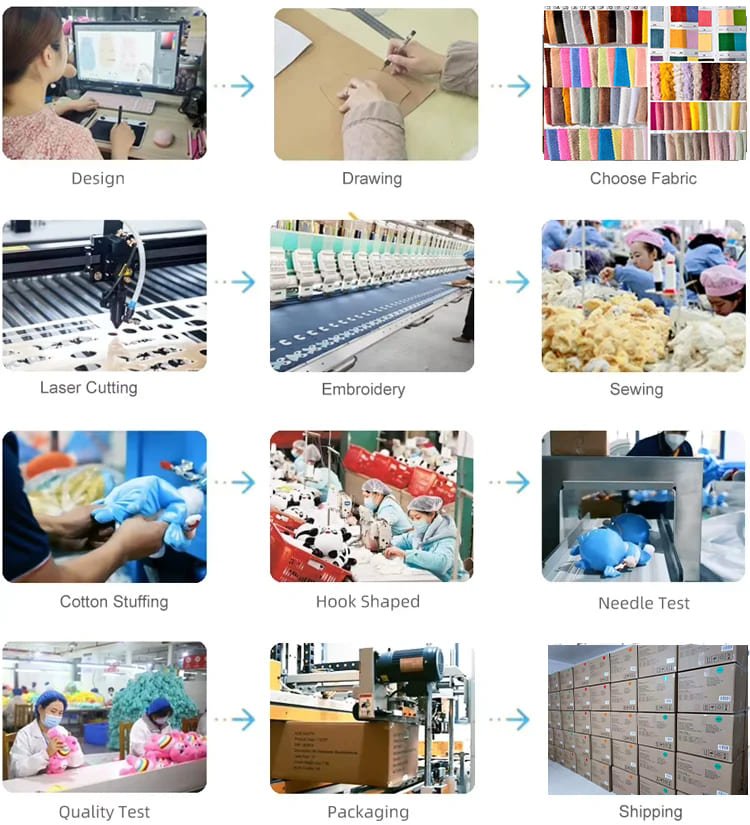

A stable plush supply chain requires a complete workflow: engineering and sampling, material staging, sewing and decoration, finishing and QC gates, then packing and warehouse preparation. This overview helps you confirm our workflow is complete and organized.

Workflow stages:

Take the Tour: 8 Stops Inside Our Factory

Where prototype samples, revisions, fit testing

Our sample room is where concepts become buildable prototypes. This area shows our iteration system: sample builds, revision rounds, review checklists, and approval records that turn prototypes into production-ready references.

What you will see:

Pattern feasibility, structure, size scaling

Pattern engineering is the bridge between artwork and repeatable production. This area demonstrates structure breakdown, proportion control, and engineering decisions for stability and attachments—so mass production doesn’t rely on handcraft luck.

What you will see:

fabric options, stuffing specs, sourcing

Many quality issues start with materials. This area shows how we manage fabric options, hand-feel goals, and batch consistency, plus how stuffing targets shape and feel. It’s key for reducing “feels different from sample” complaints.

What you will see:

mass production sewing, assembly workflow

This is the core mass production proof. You’ll see workstation workflow, handoff points, and how we keep consistency at scale. A real line shows order, repeatability, and clear work division—rather than random handcraft.

What you will see:

embroidery, applique, printing logo placement

Decoration is where plush becomes a brand asset. This area shows how we execute brand details with repeatable placement and QC checks—supporting logo readability, facial consistency, and photo impact across batches.

What you will see:

AQL inspection, needle detection, safety

Quality becomes credible when checkpoints and records exist. This area shows where we run staged QC (IQC/IPQC/FQC/OQC), how we classify defects, and what risk-control steps are used for high-impact issues like needle/metal control.

What you will see:

custom packaging, kitting, carton marking

Many shipment failures happen at packing: wrong labels, mixed SKUs, missing inserts, incorrect carton marks. This area shows how we assemble packaging, inserts, and sets with verification steps—so deliveries arrive warehouse-ready.

What you will see:

ready to ship, labeling, dispatch

Warehouse readiness is part of on-time delivery. This area demonstrates staging, carton organization, and shipment preparation—supporting smoother receiving and fewer disputes. It also connects to our milestone planning and delivery control approach.

What you will see:

For Remote Verification

Many buyers cannot visit in person. We can provide a structured tour pack: short videos per area, photo sets, and a proof link map. This helps procurement and QA validate reality without long back-and-forth messages.

Tour pack options (request-based)

Q1: Can you do a live video walkthrough?

Yes. We can schedule a guided walkthrough focusing on the areas most relevant to your project (sampling, lines, QC, packing).

Q2: Can you share photos/videos without exposing other clients’ IP?

Yes. We use controlled angles, redaction, and avoid sensitive close-ups of patterns and client marks.

Q3: What should our QA team look for during a tour?

Workflow completeness, cleanliness/organization, clear QC gates, packing verification discipline, and evidence that sampling and production are connected to repeatable standards.

Q4: How does this tour connect to your proof pages?

Each workflow stop links to a capability proof page showing how that area is managed (standards, checkpoints, and evidence options).

Verify Fast, Then Start With a Controlled Plan

Request a tour pack, or send your project essentials. We’ll reply with feasibility notes, a sampling plan, and proof links your stakeholders can review.

I am Nika, our team would be happy to meet you and help to build your brand plush.