Clear inputs beat “perfect specs”. Send the right files + decisions once, and your first sample lands closer—with fewer revision rounds.

With Uniomy’s sampling control system, we help you solve the common roadblocks below:

Start with clear inputs.

AI/PDF preferred (PNG/JPG ok for first review)

height/width + any must-keep proportions

expected MOQ / range (e.g., 500–1,000 pcs)

US / EU / UK / AU / SG / MY, etc. (for compliance planning)

kids vs adult / retail vs promotional

launch window or deadline (if any)

Top 3 must-keep priorities: features that cannot change after Round 1

Sampling-ready artwork reduces misinterpretation.

Artwork quality drives plush sampling speed and accuracy. Send the right file formats and views to translate your character design into pattern lines, embroidery/printing details, and correct proportions. Better artwork inputs reduce surprises, revisions, and time lost in Round 1.

Best formats (preferred for custom plush sampling)

Include when possible

If you only have a sketch

Lock base size early to avoid rebuilds.

You don’t need a full engineering drawing, but you do need a clear plush size target and proportion priorities. Size changes after the first sample often trigger pattern rework. Lock the base size early using a few key measurement points for faster approvals.

Provide

Helpful for better accuracy

Avoid

Define the feel goal, then match fabric and stuffing.

For custom plush sampling, “material” is not just the fabric type—it’s also the hand-feel and stuffing behavior. Share your feel goal early so we can recommend plush fabric options (minky/velboa/long pile) and stuffing targets that match your brand positioning and reduce rework.

Choose a feel goal (simple, buyer-friendly inputs)

If you have preferences

If sustainability matters

Placement rules keep logos labels consistent and readable.

Branding is a common cause of plush sample revisions. Define your logo file, decoration method (embroidery/printing/patch), and placement rules early. Clear branding inputs help us keep logo readability, alignment, and placement consistent from the first sample to bulk production.

Provide if applicable

Attachments change construction and compliance risk.

Accessories like keychains, magnets, zippers, hard parts, or electronics affect plush construction, safety, and sampling time. Mention them at the start of your custom plush sample request. Late additions often force structure changes, add revision rounds, and extend lead time.

Common accessories

Provide

Photos, samples, mood boards reduce interpretation and save revision rounds.

Reference examples make custom plush sampling faster and more accurate. A similar plush photo, a physical reference, or a clear mood board aligns style, stitching/printing expectations, finishing level, and hand-feel—often saving an entire revision round and improving internal approvals.

Best references

Only lock packaging early when it affects size or fit.

Packaging isn’t always required in early plush sampling. But if your custom plush must fit a retail box, mailer, or display format, share packaging constraints early. This prevents size rework and avoids “sample fits in hand but not in carton” issues.

Provide if packaging is already defined

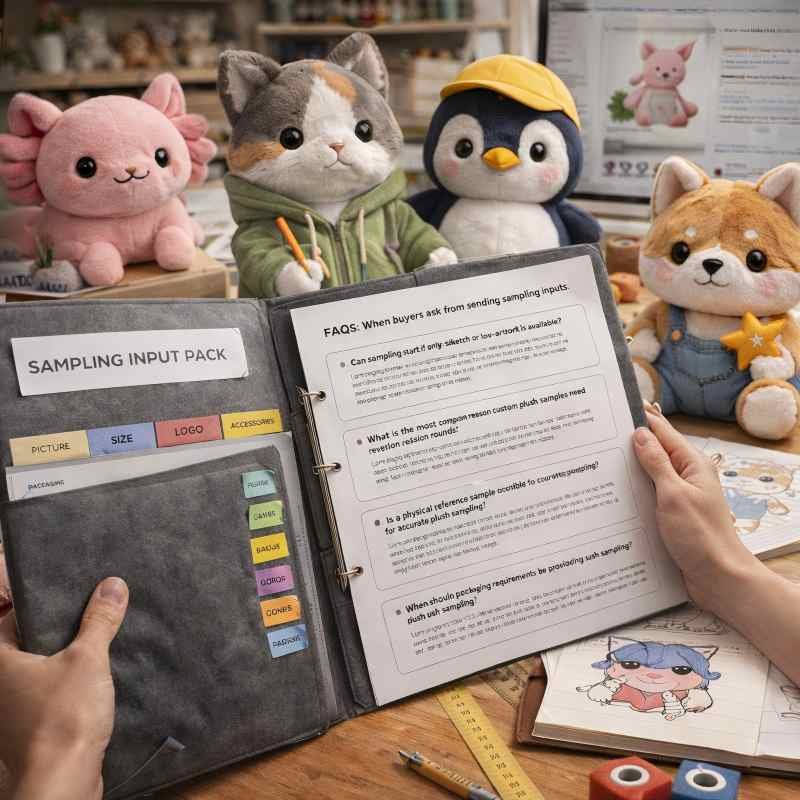

1 consolidated submission pack keeps everyone on the same version.

Sampling moves fastest when your team submits one consolidated “Sampling Input Pack.” This reduces back-and-forth and lets us respond with a clear sampling plan, timeline expectation, and Round-1 verification list—based on a single version set your team can approve against.

Sampling Input Pack checklist

Optional (helps align cost tier early)

Q1: Can sampling start if only a sketch or low-res artwork is available?

Yes. Sampling can start with a sketch or low-resolution image for feasibility review, shape direction, and method planning. To avoid revisions, include written priorities (must-keep features, acceptable simplifications) and provide vector artwork (AI/PDF) before branding placement and final detailing are locked.

Q2: What is the most common reason custom plush samples need extra revision rounds?

The most common cause is “unlocked basics”: size changes after Round 1, unclear branding placement, or late accessories/packaging constraints. A single Sampling Input Pack (artwork + size + market/age grade + feel goal + branding rules + attachments + references) keeps the first sample aligned and reduces rework.

Q3: Is a physical reference sample required for accurate plush sampling?

Not required, but highly helpful. A physical reference sample or clear reference photos (plus do/don’t notes) reduces interpretation on shape, finishing level, and hand-feel—often saving one revision round. If a physical sample can’t be sent, a competitor listing link or mood board is a good substitute.

Q4: When should packaging requirements be provided during plush sampling?

Packaging only needs to be decided early when it affects size, fit, or pack-out (window box, mailer limits, inserts, retail display requirements). If packaging is not fixed, sampling can proceed without it. If packaging is fixed, share internal dimensions and insert requirements upfront to prevent size rework later.

Q5: What information is needed for compliance planning (EU/US/UK) during sampling?

Provide the target market, intended age grade, and any channel-specific requirements (retailer rules, labeling language, special claims). Testing reports are product-specific and depend on final materials and components, so early clarity helps avoid retesting and prevents late design changes that impact timelines.

Verify Fast, Then Start With a Controlled Plan

If your team is ready to move forward, submit your Sampling Input Pack in one go. We’ll reply with a feasibility check, a recommended sample path (prototype / PP / golden sample), and the Round-1 verification list (size, branding placement, materials/hand-feel, attachments, packaging fit) so approvals don’t drift and revisions stay minimal.

I am Nika, our team would be happy to meet you and help to build your brand plush.