Most custom plush sampling delays come from unclear decisions and late changes.

Uniomy approve faster by using round-based decisions—structure first, details last—so revisions don’t reset your timeline. We offer practical solutions for your problems like:

Sampling speed is driven by decision clarity, not sewing alone.

A plush sampling timeline is not a fixed shipping-style schedule. It’s a repeatable cycle: build → review → revise → confirm. Total sample lead time depends on complexity, material decisions, feedback quality, and revision scope. This guide explains what controls speed and what creates delays. A sampling timeline is influenced by:

shape difficulty, parts count, accessories, embroidery/printing coverage

fabric type, pile length, pile direction, color matching, stuffing targets

measurable notes vs subjective comments

small detail updates vs pattern rebuild and construction changes

5 key questions to control revisions

Most programs follow a simple three-round approval path.

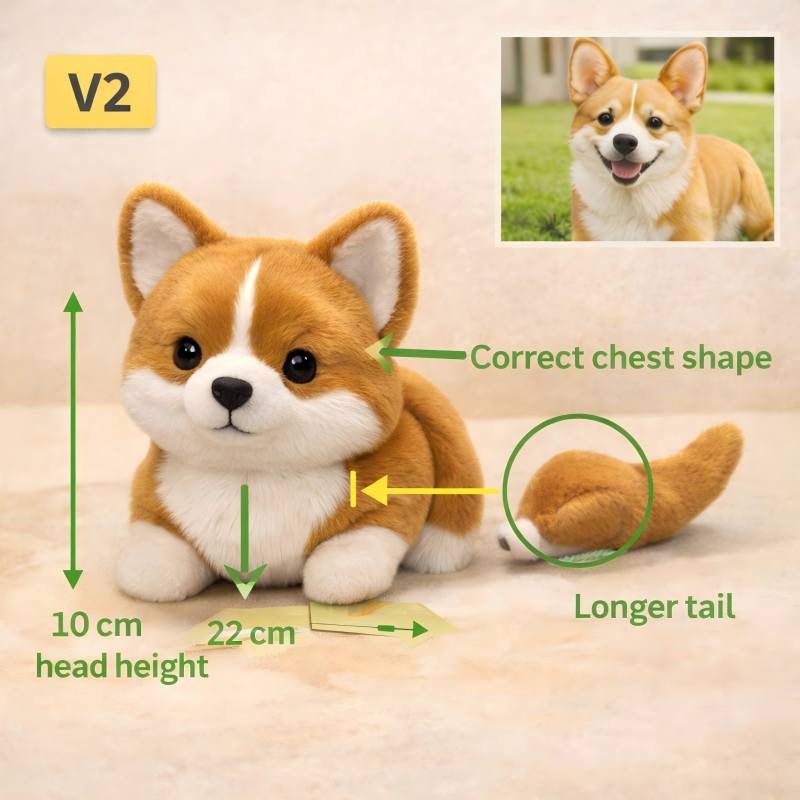

Custom plush sampling commonly follows a round-based process. V1 proves direction and feasibility. V2 corrects structure and key measurements. V3 refines details for approval. Some projects finish earlier; complex designs may need an extra round for electronics or multi-part assembly.

Staged rule: structure → measurements → placement → finishing

Trying to perfect details before structure is stable causes rework and extra rounds. Use a staged rule: structure → measurements → placement → finishing. This keeps each revision meaningful, reduces sample lead time, and prevents late changes from resetting patterns and approvals.

Measurable feedback prevents misinterpretation and lost edits.

The fastest approval path comes from clear, measurable review notes. Use a version tag, key measurements, annotated photos, and one consolidated change list per round. This reduces back-and-forth, prevents “interpretation gaps,” and ensures the next sample matches your intended corrections.

Always include:

One round = one consolidated list

Mark priorities clearly:

PP approval locks production-critical specs to protect the timeline.

Revisions stop being improvements when they start resetting construction decisions. A PP sample (pre-production sample) is a go/no-go gate that locks what matters for mass production: measurements, materials, placement map, attachments, and workmanship baseline. Use PP to prevent timeline drift before bulk production.

Move to PP when:

Do NOT move to PP when:

PP locks these fields (production-critical):

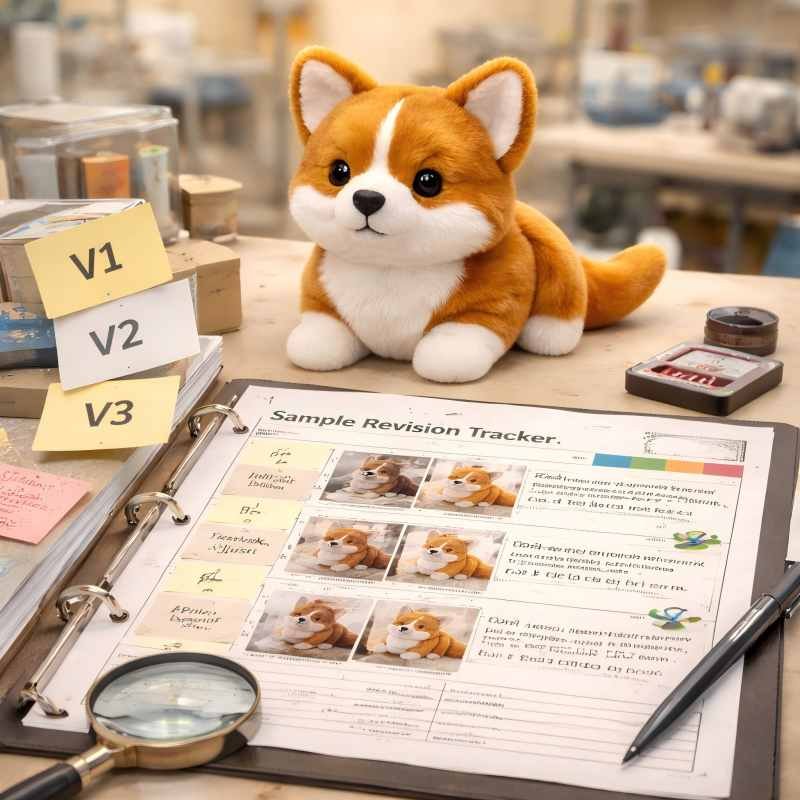

Version control keeps approvals clear and prevents silent resets.

Fast sampling requires controlled revision records. We track versions (V1/V2/V3), record what changed, and keep approval notes so your team always knows what was decided and when. This reduces disputes, supports audit-ready documentation, and makes reorders easier to repeat consistently.

Spot delay triggers early and keep approvals on schedule.

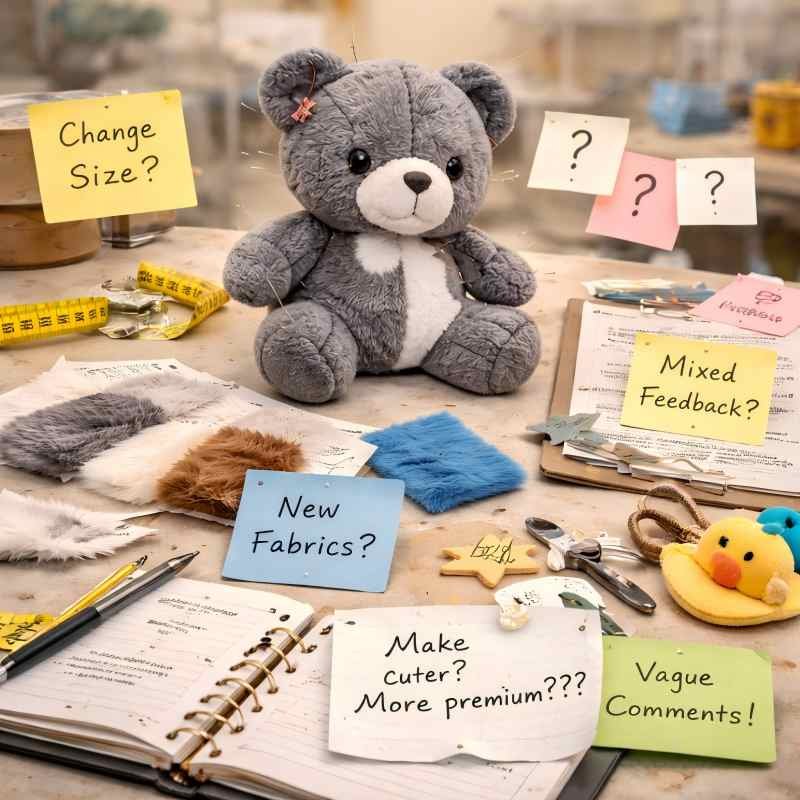

Most delays come from late changes and unclear decisions.

Sampling delays usually come from decision resets, not production speed. If you avoid the common delay triggers—size changes, fabric switching, scattered feedback, vague comments, and late accessories—most custom plush projects move smoothly through revision rounds and reach approval faster.

Top 5 delay causes:

Base size changes after V1 (pattern rebuild risk)

Fabric/pile changes (short pile ↔ long pile; pile direction requirements) without re-validating shape

Accessories/electronics added late (custom hardware, keychain parts, zippers, LED/sound modules)

Scattered stakeholder feedback with no single decision owner

Vague comments (“cuter,” “more premium”) without references, measurements, or annotated photos

Packaging or labeling requirements introduced early (retailer rules, multi-language, carton marks) that weren’t planned into the sample scope

Backward planning for Marketing, QA, Purchasing Alignment

Sampling often sits on the critical path for launches. Plan backwards from your campaign photo date, listing launch date, or retail delivery deadline. Add buffers for internal review, material confirmation, and optional testing. Pre-scheduled review meetings per round reduce delays and protect your launch window.

Plan backwards from:

Add buffers for:

Best practice:

Q1: Why does plush sampling take so long?

A: Sample lead time depends on design complexity, materials, and revision rounds. When the artwork/specs are clear and materials are standard, the first sample is typically made and dispatched in 5–7 business days. The overall “order → delivery” time also includes shipping, which varies by courier and destination. If the design requires non-standard accessories (custom hardware, special zippers, unique keychain parts, electronic modules, or uncommon trims), the timeline extends based on accessory sourcing and lead time—we confirm that lead time upfront and build it into the sampling plan.

Q2: How many sample revisions are normal for custom plush toys?

A: Most custom plush programs reach approval in 2–3 rounds (V1/V2/V3). Simple plush with clear references may approve in fewer rounds. Complex builds—many parts, multiple decoration zones, accessories, or electronics—often require an extra round to validate structure and repeatability.

Q3: What changes usually require a new sample round (instead of a small tweak)?

A: Changes that affect the pattern or construction typically trigger a new round: base size changes, fabric/pile changes, adding/removing accessories, moving attachment positions, or altering the silhouette. Detail-level updates (trim, embroidery density, small placement micro-adjustments) are usually best saved for later rounds after structure is stable.

Verify Fast, Then Start With a Controlled Plan

Share your product type, size, target market, and launch date. We’ll return a round-based sampling plan (V1→V2→V3), plus what to lock in each round to prevent resets. If you already have a reference, we’ll flag feasibility risks before you pay for extra revisions.

I am Nika, our team would be happy to meet you and help to build your brand plush.