Custom plush pricing is the combined result of materials + labor time + decoration + accessories + packaging + delivery requirements.

Uniomy’s controlled quoting system helps solve the common pricing blockers below:

Note: This page explains pricing logic and quote inputs—not public list pricing.

6 predictable drivers explain most price differences.

Most unit cost differences come from a few controllable drivers: size, sewing complexity, fabric/feel level, decoration method, accessories, and packaging/handling rules. If you lock these variables early, pricing becomes stable, tier tables become usable, and reorders become easier.

Bigger size uses more fabric and stuffing and usually increases sewing minutes per unit.

More pattern pieces, 3D shapes, layered details, and tight tolerances increase labor time.

Dense premium fabrics, specialty textures, and custom colors raise cost and can affect lead time.

Embroidery, appliqué, and printing have different cost, readability, and durability tradeoffs.

Keychains, zippers, magnets, electronics, outfits, and add-ons increase parts cost and handling/QC time.

Retail boxes, kits, barcode labeling, and strict carton rules add materials + packing labor.

4 core pricing blocks: quote structure, MOQ, tier breaks, and sampling costs.

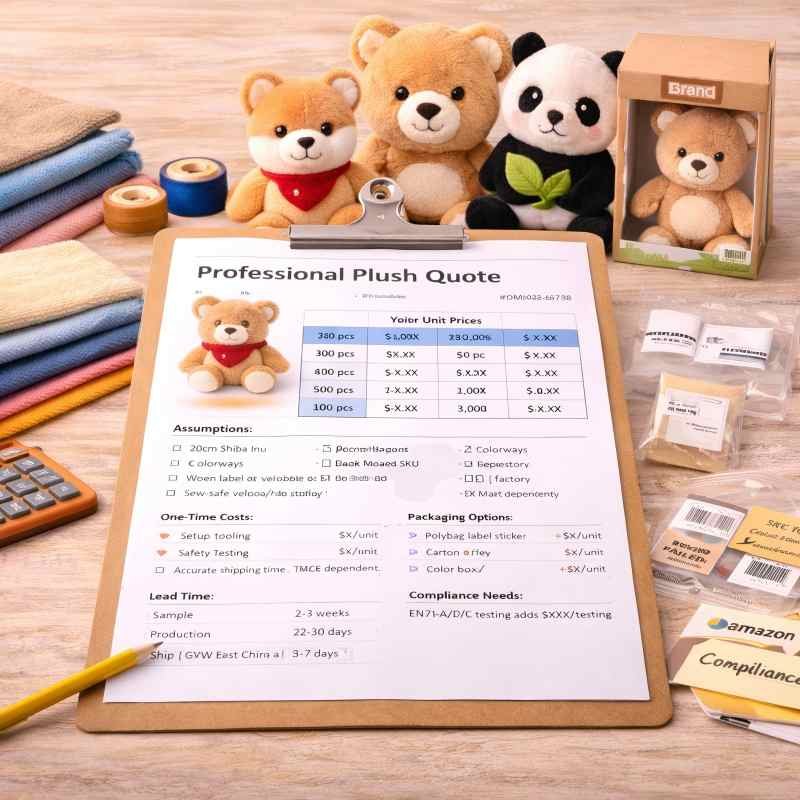

A usable quote shows tiers, assumptions, and the real cost drivers

A professional quote is more than a unit price. It should show tiered unit pricing, key assumptions (spec and pack-out rules), optional packaging add-ons, and a lead time estimate aligned with sampling rounds and shipping method. This makes supplier comparisons fair and reorders forecastable.

A typical quote includes

MOQ is where production becomes stable enough to price realistically.

MOQ is not a factory preference—it’s the point where sourcing, setup, and production flow become stable enough to deliver a reasonable unit cost. MOQ depends on fabric sourcing, colorways/SKUs, decoration setup, accessories, and packaging rules. Lower MOQ usually requires simplifying variables.

What pushes MOQ up

How to keep MOQ lower (without sacrificing the brand)

Tiers show real price breaks for same spec.

Tiered pricing shows how unit cost changes as quantity increases. Early tiers are higher because setup and variability are concentrated; higher tiers spread fixed costs and stabilize line efficiency. Use tiers to plan launches, budget approvals, and reorder forecasts—without chasing unrealistic unit prices.

Go deeper please review

Reduce rounds and resets to protect budget.

Sampling fees reflect pattern work, revision rounds, and any special processes needed to reach a production-ready approval baseline. For ongoing programs, sampling is a project investment and may be handled with structured credit logic after bulk order confirmation (project-dependent). The best savings come from fewer resets.

What affects sampling cost most

How to reduce sampling cost (and time)

Lead time is controllable when shipping and approvals are planned early.

Lead time is determined by sampling rounds, production complexity, SKU count, packaging rules, and shipping method. The fastest way to hit a hard launch date is early spec lock, fewer moving parts, and choosing shipping method early (or split shipments) to protect your arrival window.

The biggest timeline drivers

Go deeper

Your complete inputs produce a quote your team can approve internally.

The fastest usable quotes come from complete inputs. Send the items below and we’ll reply with a tier table, the top unit-cost drivers, and a lead time plan aligned with sampling milestones and shipping method—so you can decide internally without repeated re-quotes.

Please share:

6 Key Differences in a Procurement-Grade System

A “perfect sample” VS A “perfect bulk system”

What typical suppliers run into:

A “perfect sample” exists, but bulk units change—face placement shifts, seams vary, fabric feel drifts, packaging changes quietly.

What Uniomy controls instead:

Version locking after approval: the approved reference becomes the bulk benchmark, not a suggestion.

Spec boundaries defined early: what can change vs must-not-change (fabric, pile direction, fill feel, embroidery placement, packaging layout).

Change control discipline: any change triggers review before it hits production—no silent substitutions.

Customer Benifits:

Bulk stays matched to the approved reference, and reorders don’t restart the project from scratch.

A “good-looking batch” vs repeatable workstation execution.

What typical suppliers run into:

Unit-to-unit variation appears even within the same batch—tightness changes, seams drift, alignment shifts, finishing looks inconsistent.

What Uniomy controls instead:

Standard station-by-station steps: repeatable sewing path and handoff points (not “whoever is available”).

Key alignment points protected: eyes/nose/limb symmetry, openings and closures, hidden stitch finishing.

Feel and weight become measurable: fill weight ranges and fill-zone logic prevent random feel variation.

Customer Benifits:

Fewer reworks, fewer surprises at receiving, and more consistent customer reviews once the SKU scales.

A “nice fabric swatch” vs stable wear-and-wash behavior.

What typical suppliers run into:

Fabrics look good in photos but fail in bulk use: shedding, pilling, dye transfer, shrinkage, or decoration incompatibility.

What Uniomy controls instead:

Material screening by use intensity: display vs frequent handling vs high-friction items (keychains).

Risk flags before sampling: shedding, colorfastness, pile direction stability, print/embroidery suitability.

Substitution logic: alternatives are chosen to preserve the same feel target and appearance.

Customer Benifits:

Fewer compliance and durability surprises, and less re-testing caused by material drift.

A “sharp mockup” vs locked placement + repeatable pack-out.

What typical suppliers run into:

Logos become unreadable, edges lift, placement drifts, packaging varies, and kitting errors appear at scale.

What Uniomy controls instead:

Use-case selection: decoration method chosen by handling intensity (kids / display / keychain friction).

Placement rules locked: size ratio, edge finishing, stabilizer choices, wash/wear outcome.

Pack-out checklists: packaging layout and kitting accuracy kept repeatable unit to unit.

Customer Benifits:

Brand presentation stays consistent, unboxing stays repeatable, and warehouse receiving gets smoother.

“Looks fine” vs pass/fail rules with stop-and-fix control.

What typical suppliers run into:

Quality checks exist, but defects repeat; production continues; issues are discovered only when cartons arrive.

What Uniomy controls instead:

AQL pass/fail rules: defect grading + sampling logic aligned before bulk.

Stop-and-hold triggers: repeated drift pauses the run before defects spread.

Re-check after fix: the first good-after-fix unit becomes the new benchmark for the remaining batch.

Customer Benifits:

Lower defect volatility, fewer last-minute firefights, and clearer accountability when receiving teams inspect.

“Trust us” vs traceable records that protect shipments.

What typical suppliers run into:

Needle/metal incidents become serious risks, or post-delivery disputes have no traceable evidence trail.

What Uniomy controls instead:

Needle tracking + detection coverage: controlled workflow, not luck.

Batch traceability fields: production lots mapped to shipments and labeling fields.

Compliance support paths: document pack structure, testing workflow, labeling/traceability checklist.

Customer Benifits:

Lower risk exposure and faster resolution if issues arise after shipment.

Q1: Can you quote without a final design file?

Yes. Share reference images and target size. We can provide a budgetary tier range and highlight main cost drivers. Final pricing requires spec lock.

Q2: Why do quotes change after sampling?

Usually due to spec changes: fabric type, decoration method, accessories, packaging rules, or SKU count. We minimize this by locking must-not-change items early.

Q3: What’s the best way to reduce unit cost?

Control sewing complexity, reduce SKU count at launch, standardize packaging/carton rules, and scale into stable tiers.

Q4: How do I plan for a hard launch date?

Use the Gantt templates and choose shipping method early. Consider split shipments for launches.

Control the Budget for Your Entire Custom Plush Project

Share your specs and target quantity tiers. We’ll return a tier table, the top unit-cost drivers, and a lead time plan aligned with sampling milestones and your preferred shipping method.

I am Nika, our team would be happy to meet you and help to build your brand plush.