Compliance isn’t “one certificate.” It’s a document chain: factory qualifications, SKU-specific test evidence, and market documents issued by the brand/importer. You may have the following troubles and see how we help:

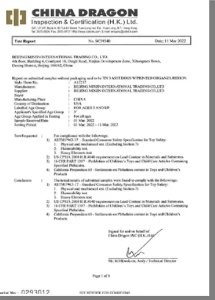

Factory certificates show whether a factory is audit-ready. SKU-specific testing proves a specific plush build is compliant for a specific market.

What it proves: Supplier entry qualification.

Factory certificates show whether a factory runs an audit-ready management system. They help buyers qualify suppliers, but they do not prove a specific plush SKU is compliant for a specific market.

What it covers

Quality / process management systems

Social responsibility / ethical audit readiness (when applicable)

Factory-level controls and documentation discipline

What it does NOT replace

Product testing reports for a specific SKU/version

Market documents held by the brand/importer (EU/UK/US)

What it proves: Shipment release proof.

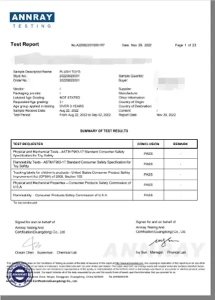

SKU-specific compliance is built per product and market. It proves the tested plush version (materials, components, and pack-out/labels) matches what will ship—and provides the evidence buyers and regulators review.

What it includes

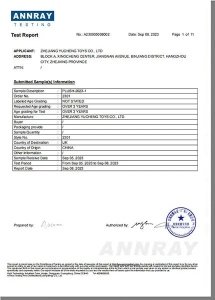

Third-party lab test reports (per SKU/version)

Technical documentation (market-specific)

Labeling, barcode/SKU alignment, and traceability records

What changes scope

Eyes/nose, prints/coatings, magnets/weights, electronics, small parts

Any material/component/pack-out version change may trigger re-checking coverage

Factory Qualification Certificates Buyers Commonly Expect

These factory certifications are common sourcing requirements for brands, retailers, and licensors. They don’t certify a specific plush SKU, but they help qualify a supplier: typically a quality system plus a social audit, with sustainability certificates added when claims or retailer policies require them.

ISO 9001 (Quality Management)

Signals stable control for incoming/process/final inspection, CAPA, and document control—often treated as a default requirement for serious B2B sourcing.

ICTI / Ethical Toy Program (IETP)

Toy-focused ethical audit recognized by many brands and licensing programs.

BSCI or SMETA (Sedex)

Common retail and marketplace threshold for labor, workplace safety, and ethical sourcing verification.

GRS / RCS (Recycled content chain-of-custody)

Used when recycled fabric/fill claims must be verified with traceability.

OEKO-TEX (Textile chemical safety expectation)

Often requested for skin-contact or baby-focused programs.

FSC (Paper packaging sourcing)

Helps when hangtags, inserts, cartons, or gift boxes require certified paper sourcing.

Common baseline: ISO 9001 + (BSCI/SMETA/ICTI), with GRS/RCS/OEKO-TEX/FSC added when claims or retailer policies require them.

Compliance Documents held by brands, Factory Support Required

In US/EU/UK compliance, the responsible party placing goods on the market signs declarations and holds technical files. Factory support is still critical: test samples, BOMs, construction notes, material declarations, and traceability fields often determine whether documentation is complete and defensible.

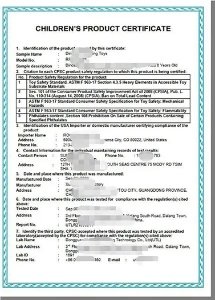

What it is: CPC (Children’s Product Certificate) is issued by the US importer or domestic manufacturer.

Factory support typically includes:

Common test basis: ASTM F963 + CPSIA substance limits (lead, phthalates, etc., depending on components).

DoC + technical file

What it is: EU Declaration of Conformity (DoC) + technical documentation kept by the responsible party.

Factory support typically includes:

UK DoC + technical file + marking rules

What it is: UK DoC + technical file + correct marking rules (UKCA/CE depending on policy at the time).

Factory support: largely mirrors EU requirements: testing scope + technical file evidence + traceability and labeling fields.

3 important points as Evidence + testing + labeling.

The factory evidence that closes gaps.

Most compliance delays come from missing details—not from missing goodwill. This list covers the documents and data most frequently requested by procurement and QA: BOM clarity, construction notes, supplier declarations, test alignment, and traceability fields that remain stable from sample to bulk.

Product BOM / materials list: fabric, fill, thread, accessories, eyes/nose, zippers, velcro, sound paper/bell, electronic modules

Construction notes: fixation method (stitching / adhesive / heat-seal / riveting), small-part dimensions, pull-force points

Sample-to-bulk consistency note: tested sample matches the locked production spec

Batch traceability fields: production date/lot, shipment lot, work order number

Supplier documents: COA, material declarations, SDS (inks/adhesives), recycled certificates (GRS/RCS)

If issues happen: corrective actions, re-test records, change control notes

Testing Labs, Workflow, Cost Responsibility

Testing scope depends on target market, age grading, structure, and components. Lab coordination can follow a nominated lab or a typical partner workflow. Third-party testing fees are paid by the brand/importer; support covers samples, document packaging, tracking, and change control.

Testing stays predictable when scope is defined early and the submitted sample matches the locked version.

Scope drivers: market/channel, age grading, structure, components, claims

Lab routes: buyer-nominated lab or coordinated partner workflow

Support includes: submission-ready samples, document packaging, status tracking, change control

Cost note:

Third-party testing fees are paid by the brand/importer.

Traceable batches, fewer disputes.

Labeling is not just artwork—it’s a repeatable field system tied to batch traceability. When label fields, language, and batch IDs stay consistent, compliance documentation remains defensible, warehouse receiving is smoother, and reorders can be linked back to the same approved spec.

Compliance files remain usable when identifiers stay consistent from sample to shipment.

Required label fields (language + warnings when applicable)

Batch ID mapping (materials → production lot → inspection → shipment)

Carton marks + shipment linkage (carton labels ↔ packing list ↔ PO)

Pack-out checks to keep labeling repeatable unit to unit

Lock scope before testing.

To confirm compliance scope accurately, share target market (US/EU/UK), age grading, reference images, size, quantity range, materials and components (eyes/nose, prints, electronics), and packaging/labeling requirements. A clear response can include a document checklist, test scope suggestion, and a realistic timeline. Third-party testing fees are paid by the brand/importer.

I am Nika, our team would be happy to meet you and help to build your brand plush.